BLOG

DELCO Valve leverer forskellige optimale løsninger til industrielle ventiler, især til reguleringsventiler.

TAGS

Kontakt os

What is a Valve? A Complete Guide to Types, Parts, and Functions

- DELCO-ventil

An Introduction to Valve Types, Applications, and Industries: A Comprehensive Guide to Valve Selection and Use

Valves are critical components in industrial equipment, widely used to control the flow of fluids and ensure the safe, stable operation of systems. From oil and gas, chemical processing, and power generation to metallurgy, mining, and water treatment, valves play an indispensable role. This article provides a detailed introduction to valve types, their fields of application, their roles across various industries, and a practical, step-by-step guide for valve selection and maintenance.

What is a Valve? Basic Concepts

A valve is a device used to control the flow of a fluid (liquid, gas, slurry, etc.) by starting, stopping, or regulating its flow, preventing backflow, or controlling its pressure. A typical valve consists of a body, a seat, a disc (or core), sealing components, and an actuator. Based on different operating principles and structures, valves are classified into numerous types to meet diverse industrial demands.

The Basic Functions of a Valve:

On/Off (Isolation): Valves like gate valves and ball valves can completely open or close a flow path.

Throttling (Regulation): By adjusting the degree of opening, valves such as globe valves and control valves can precisely regulate the fluid flow rate.

Backflow Prevention: Devices like check valves ensure fluid flows in only one direction, protecting upstream equipment.

Pressure Regulation: Some valves, such as pressure reducing valves and safety valves, automatically regulate or maintain system pressure within a set range.

Valve Types and Their Applications

1. Electric Valves (Electrically Actuated Valves)

An electric valve uses an electric actuator for on/off or modulating control. It is ideal for applications requiring remote control, automation, or precise flow regulation. With stable response and accurate control, it is a common device in automated control systems (e.g., DCS, PLC).

Applications:

Chemical Processing: For precise flow control in chemical reaction processes.

Power Generation: In boiler feedwater and steam control systems to regulate the flow of water and steam.

2. Pneumatic Valves (Pneumatically Actuated Valves)

A pneumatic valve is driven by a compressed air actuator. It is characterized by fast response, intrinsic safety (explosion-proof), and relatively low cost. Pneumatic valves are frequently used in automated systems, especially in environments with high safety requirements, such as those with flammable or explosive materials.

Applications:

Oil & Gas: For rapid shutdown and flow regulation in oil and gas pipelines.

Metallurgy: For controlling gases like oxygen and coal gas in smelting processes.

3. Control Valves

A control valve is the final control element in an automated system, used to precisely manage the flow rate, pressure, temperature, or level of a fluid. It typically works in conjunction with sensors and controllers, receiving a control signal to change the valve’s opening.

Applications:

Water Treatment: To accurately regulate chemical dosing and water flow, ensuring stable water quality.

Chemical Processing: To adjust the temperature and pressure in reactors, ensuring stable production processes.

View Technical Specifications & Case Studies for Control Valves

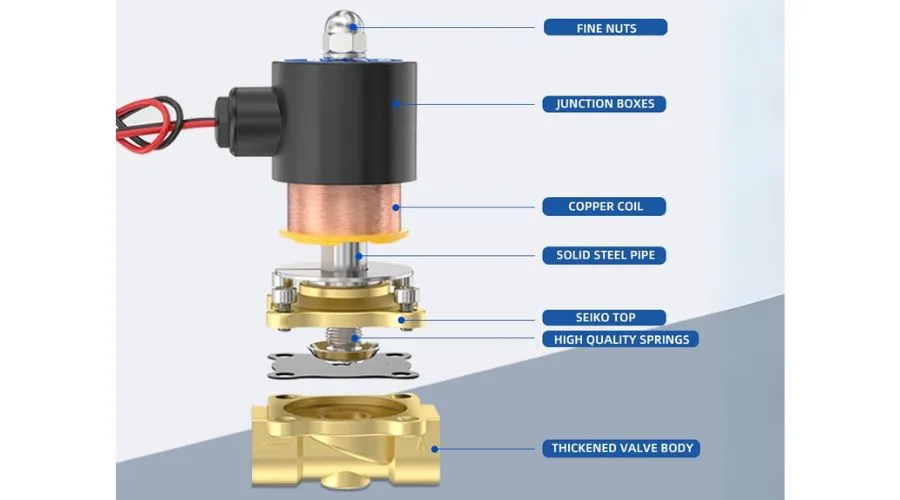

4. Solenoid Valves

A solenoid valve is controlled by an electromagnetic coil that opens or closes the valve when energized or de-energized. It offers an extremely fast response time (in milliseconds) and a simple structure, making it suitable for applications requiring rapid and frequent on/off switching.

Applications:

Automated Production Lines: For controlling pneumatic cylinders and fluid dispensing systems.

HVAC & Refrigeration: For quickly opening or closing refrigerant lines.

5. Ball Valves

A ball valve uses a spherical disc with a hole (a bore) to control flow. A 90-degree turn of the actuator handle or stem fully opens or closes the valve, allowing for quick operation. Due to their compact structure, excellent sealing performance, and low flow resistance, they are widely used in high-pressure, high-temperature, and quick-shutoff applications.

Applications:

Petrochemicals: In long-distance pipelines and storage facilities for oil and natural gas.

District Heating: For regulating water and steam flow in boiler and heat exchange systems.

6. Gate Valves

A gate valve uses a flat gate (a wedge or slab) that moves up and down to start or stop fluid flow. It provides an unobstructed path when fully open, resulting in very low flow resistance. It is designed primarily for fully open or fully closed service and is not suitable for throttling.

Applications:

Natural Gas Transmission: For isolating main sections of pipelines.

Water Supply & Drainage: For main line isolation in water intake and drainage systems.

7. Globe Valves

A globe valve uses a movable disc and a stationary ring seat in a generally spherical body to stop or regulate flow. Its design provides excellent sealing when closed. Although it has higher flow resistance than a gate valve, it is ideal for applications requiring precise throttling and reliable shutoff.

Applications:

Power Generation: For regulating steam and high-temperature water flow in boiler systems.

Chemical Processing: For precise flow control in delicate chemical reaction processes.

8. Check Valves

Also known as non-return valves, check valves are designed to allow fluid to flow in only one direction. They operate automatically, opening with forward flow and closing against reverse flow, preventing backflow that could damage equipment.

Applications:

Pump Outlets: To prevent backflow from damaging the pump.

Chemical Processing: To prevent the mixing or backflow of different media that could disrupt a reaction.

How to Select the Right Valve for Your Application (A Step-by-Step Guide)

Choosing the wrong valve can lead to system inefficiency, leaks, or even safety hazards. Follow these steps for a systematic selection process:

1. Identify the Service Medium:

Medium Type: Is it a liquid, gas, steam, or slurry? Is it corrosive? Does it contain solid particles? This will determine the primary valve type and the required body/seal materials.

Example: Abrasive media with particles are not suitable for globe valves with high-sealing seats; a V-port ball valve or a knife gate valve would be a better choice.

2. Determine the Pressure and Temperature:

Operating Conditions: Identify the maximum and minimum operating pressure and temperature of the system. The selected valve must have a corresponding pressure rating (e.g., PN16, Class 150) and temperature range.

3. Choose the Method of Operation:

Manual, Pneumatic, Electric, or Hydraulic? This depends on control requirements, safety considerations, and budget. Choose pneumatic or electric for remote automated control; select manual for simple, infrequent operations.

4. Consider the Functional Requirement:

Simple On/Off? Choose a ball, gate, or butterfly valve.

Need to Regulate Flow? Choose a globe, control, or V-port ball valve.

Preventing Backflow? A check valve is required.

5. Specify Material and Connection Type:

Body Material: Select based on the medium’s corrosiveness and temperature. Common materials include cast iron, carbon steel, stainless steel (304, 316), copper alloys, and PVC.

Connection Type: Flanged, threaded, welded, or compression? This depends on pipe size, pressure class, and ease of installation and maintenance.

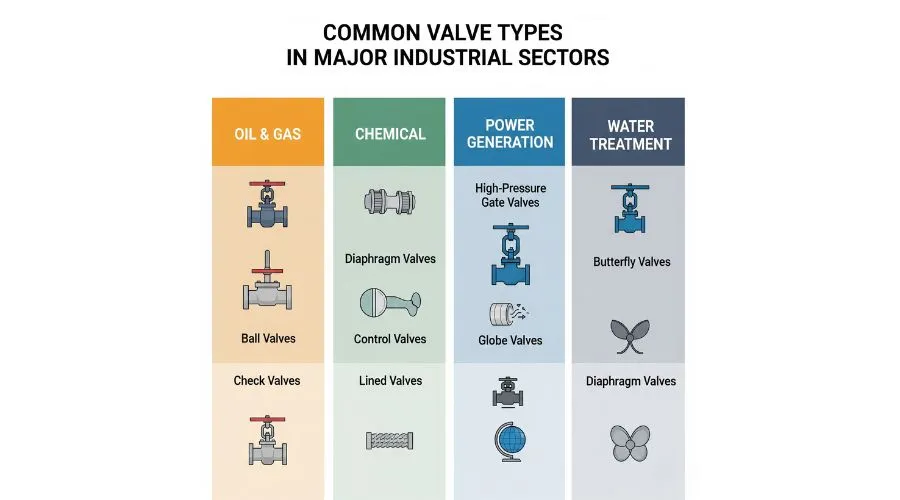

The Critical Role of Valves Across Industries

Oil & Gas: Control the flow of oil and gas, isolate pipeline sections, and regulate pressure. API-standard ball, gate, and check valves are commonly used, with stringent requirements for materials and sealing.

Chemical: Precisely control fluid flow rates, temperatures, and pressures in chemical reactions. Control valves, diaphragm valves, and corrosion-resistant ball valves are frequent choices.

Power Generation: Regulate the flow of water and steam in boilers to ensure the safe and stable operation of generator units. High-temperature, high-pressure gate, globe, and control valves are key equipment.

Water Treatment: Adjust water flow, pressure, and chemical dosing to meet quality standards. Butterfly valves, diaphragm valves, and PVC valves are widely used.

Metallurgy: Control the flow of cooling water, gases, and liquid metals to ensure smooth smelting processes. Abrasion-resistant and high-temperature ball valves and knife gate valves are common.

Valve Maintenance and Inspection

Over time, valves may suffer from leaks, wear, and other issues, making regular inspection and maintenance essential.

Periodic Inspection: Check valve seals to ensure there are no internal or external leaks when closed.

Rengøring og smøring: Keep moving parts, such as the stem, clean and lubricated to prevent sticking.

Funktionel afprøvning: Periodically test critical valves (especially during major shutdowns) to check their response time and control capabilities.

Frequently Asked Questions About Actuator Valves

What is the main difference between a ball valve and a gate valve?

When should I choose a pneumatic valve over an electric valve?

What do "DN50" or "PN16" on a valve mean?

Conclusion and Outlook

Valves are the essential joints and conduits of modern industrial systems. From oil and gas to water treatment, and from chemicals to power generation, they ensure the precise control of fluid flow and system safety. By systematically considering the medium, pressure, temperature, and control needs, you can accurately select the right valve type and material for your system, effectively boosting operational efficiency and safety. Regular inspection and maintenance are also key to ensuring the long-term, stable performance of your equipment.

Need a Professional Valve Solution?

With over 15 years of industry experience, we provide high-quality valve products and technical support to clients worldwide.

Contact Our Technical Experts for a One-on-One Consultation