La selección de cálculos, el control de calidad, la inspección, el servicio y otras etapas de producción garantizan que los clientes no tengan preocupaciones.

TAGS

Válvula de control

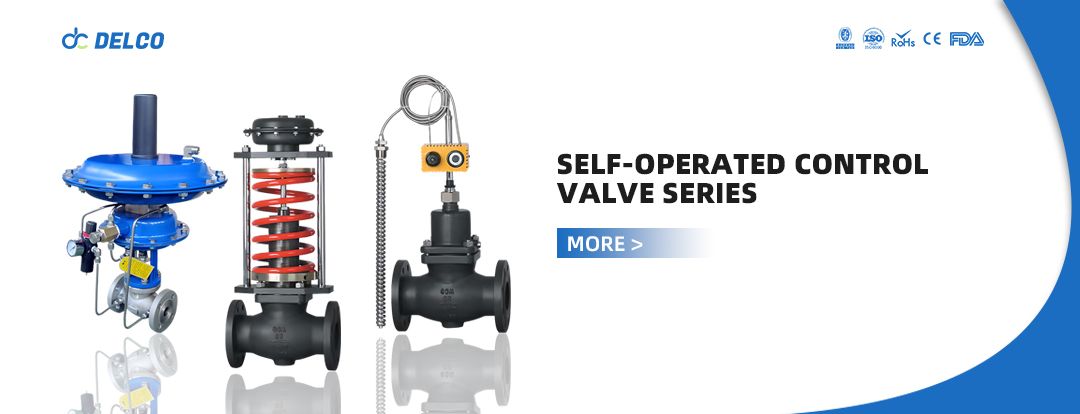

Delco specializes in the manufacturer of control valve, Which are essential components in various industrial processes, offering precise control over fluid flow, pressure, and temperature.

✅Electric Regulating Control Valve: Built-in Servo System | Precision Control | Response Speed | Low Maintenance

✅Pneumatic Diaphragm Control Valve: Small pressure drop loss | High Flow rate | High accuracy of flow characteristics

✅Self-Operated Pressure Control Valve:No External Power | Cost-effective | Fewer components | Reliability

✅Internal Structure Types: Single Seat, Double Seat, Sleeve type

✅Flow characteristics: Equal percentage, Linear, Quick-opening

✅Connection: Flange: FF, RF, RJ and LG; Thread: DIN, NPT, RC, BSP, G; Welding etc.

Application: Oil &Gas,Food & Beverage,Water & Wastewater,Ultra Pure Water, Desalination, Chemical, Textile, Pharmaceutical, and Power Industries

Want to learn more about our control valves and other valve products? Whether you need a customized solution or have any questions about our products, Delco Valves is happy to provide you with expert advice and service. Please fill out the inquiry form below or contact our customer service team directly. We will provide you with the most appropriate quote and technical support as soon as possible. We look forward to working with you!

Obtenga un presupuesto instantáneo

Un buen proveedor no sólo puede despreocuparle, sino también permitir que su empresa se desarrolle de forma sostenible y que su marca acumule continuamente reputación de servicio y calidad.

What is a control valve?

A válvula de control is a critical device used to regulate fluid flow, pressure, and temperature. It precisely controls the flow of media in pipelines by adjusting the valve opening, thereby ensuring the stability and efficiency of industrial processes. Control valves are often used in conjunction with automation systems to enable remote control and precise regulation, making them an indispensable component of modern industrial production.

Control Valve Design Advantages

- Precise Control: Control valves precisely regulate fluid flow and pressure, ensuring optimal system operation and avoiding energy waste.

- High Reliability: Manufactured from corrosion-resistant and high-temperature resistant materials, they ensure stable operation under extreme operating conditions.

- Fast Response: Modern control valve designs feature intelligent actuators that quickly respond to signal changes, ensuring instantaneous regulation.

- High Durability: Control valves are designed with a focus on wear resistance and sealing, extending their service life and reducing the need for frequent maintenance.

Industrias y aplicaciones de las válvulas de control

Control valves are widely used in various industries, including but not limited to:

- Oil and Gas: During pipeline transportation and processing, control valves help precisely regulate fluid flow and pressure, ensuring safety and efficiency.

- Chemical and Pharmaceutical Industries: Control valves regulate temperature, pressure, and liquid flow during chemical reactions or pharmaceutical production to ensure product quality.

- Power Industry: In power plants, control valves control steam flow and pressure, helping to regulate boiler and turbine operation.

- Water Treatment: In wastewater and drinking water treatment processes, control valves precisely regulate water flow to optimize treatment results.

- Control Valve Maintenance and Repair Regular maintenance and repair are essential to ensure long-term, stable operation of control valves. Key maintenance and repair tasks include:

- Regular Seal Inspection: Check seal wear to prevent leaks.

- Cleaning and Lubrication: Regularly clean valve components, especially the actuator and valve body, to prevent deposits that affect performance; and lubricate moving parts to reduce wear.

- Replacing Wear Parts: Regularly replacing commonly used valve components, such as O-rings and actuators, can extend valve life.

- Performance Testing: Regularly test valve performance to ensure that response speed and flow regulation meet requirements.

Why Choose Delco Valves?

Extensive Industry Experience: As a valve manufacturer with over 20 years of experience, Delco Valves offers professional valve solutions for a wide range of industries.

Quality Assurance: We utilize high-quality raw materials and advanced manufacturing processes to ensure that each control valve delivers exceptional performance and reliability.

Customized Services: Delco offers personalized control valve customization services to meet the specific needs of diverse industries and applications.

Global Service Network: Regardless of your location, Delco provides timely technical support and after-sales service to ensure the smooth operation of your system.

Innovative Technology: Our R&D team is constantly committed to innovation, ensuring our products remain at the forefront of the industry and meet the evolving control valve needs of modern industry.

Choose Delco Valves and let us provide you with the highest-quality control valve solutions for your industrial applications!

Guía de compra

● Confirme la tamaño de la válvula que necesita. Ofrecemos esta válvula de bola motorizada de PVC de 1/2 pulg. a 4 pulg.

● Confirme la material del cuerpo de la válvula que necesita. Ofrecemos esta válvula de bola motorizada de PVC en material UPVC, CPVC, PPH y PVDF.

● Confirme la norma de conexión. Ofrecemos esta válvula de bola motorizada de PVC en las normas ANSI, JIS, DIN y UK.

● Confirme la presión y temperatura de trabajo. La presión y la temperatura son los puntos importantes y los que pueden afectar al coste.

● Confirme la tensión que necesita. El voltaje adecuado puede ayudar a que su válvula funcione mejor.

● Díganos su medio. Cada medio tiene características diferentes y le ayudaremos a seleccionar la válvula en función de los requisitos del medio.

● Confirme la tipo de actuador que necesita. Disponemos de actuadores eléctricos para válvulas de tipo encendido/apagado, modulante, inteligente, a prueba de explosiones, IP68 y de retorno automático para su proyecto.

Si tiene algún requisito, díganoslo, como el material del núcleo, el material de sellado o la norma de conexión. Le ayudaremos a personalizar la válvula que necesite.

Para más información, envíenos un mensaje. Le enviaremos un presupuesto en 2 horas. [email protected]

Póngase en contacto con nosotros

Si tiene alguna pregunta o necesidad sobre válvulas de control, válvulas motorizadas, válvulas neumáticas, electroválvulas u otras válvulas industriales, no dude en ponerse en contacto con nosotros para una mayor comunicación.

About DELCO Valves

El pedido es sólo el principio de nuestro servicio. Tratamos a cada cliente con seriedad y sinceridad, esforzándonos por satisfacer sus requisitos personalizados lo mejor posible. Nuestro compromiso va más allá de la venta inicial; nuestro objetivo es proporcionar soluciones de válvulas rentables que satisfagan las necesidades específicas de cada cliente. Mantener los intereses de nuestros clientes es la base de nuestro desarrollo, y hacemos hincapié en establecer relaciones a largo plazo basadas en la confianza, la fiabilidad y el beneficio mutuo.

Además, proporcionamos un apoyo integral y servicios posventa para garantizar que nuestros clientes tengan una experiencia sin fisuras desde la compra hasta la implementación. Ya sea mediante asistencia técnica, entrega rápida o mantenimiento continuo, nos comprometemos a apoyar a nuestros clientes en cada paso. Nuestro objetivo es ser algo más que un proveedor; aspiramos a ser un socio de confianza en el éxito de nuestros clientes, ofreciendo soluciones innovadoras y un servicio inigualable.