Kami bukan sahaja menyediakan sebut harga yang mudah, tetapi kami pakar dalam pemilihan, pengiraan dan lukisan.

Pilihan Teratas

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Injap Solenoid yang dikendalikan oleh Juruterbang Baca lagi

DELCO Normally Closed Stem Welded Pneumatic Angle Seat Piston Valves

DELCO itu Welded Pneumatic Angle Seat Piston Valves are designed for use with all types of liquids and gases. Valves made of copperplate are ideal for applications involving water, oil, and compressed air. On the other hand, the stainless steel version is suited for both neutral and aggressive liquid and gaseous media. These valves are also capable of operating in rough vacuum environments. The maximum working pressure is 16 bar (232 psi), though this may vary depending on the specific valve model.

model: Welded Angle Seat Valve

Julat Saiz: 1/2”~2-1/2”

Julat Tekanan: 0~1.6MPa

Bahan: Stainless Steel 304/306

Edit Kandungan

DELCO Pneumatic Welded Angle Seat Piston Valves

A pneumatic angle seat valve offers a high flow rate and can operate at zero pressure difference and high temperatures. It is also suitable for handling high viscosity and dirty media. To operate in an explosive environment (Eex area), simply place the pilot valve outside the area. The valve is controlled by a pneumatic actuator driven by a three-way solenoid valve. The pilot medium pressure enters the actuator cylinder, pushing the piston to open or close the gasket through the stem. The gasket returns to its default position thanks to the return spring in the pneumatic actuator.

There are two types of pneumatic angle seat valves: single-acting and double-acting.

Single-Acting Valve

- Design: Typically has one port on the pneumatic head.

- Operation: Uses a spring to return to its default position. It is further classified into normally open and normally closed types based on the spring function.

Double-Acting Valve

- Design: Typically has two ports on the pneumatic head.

- Operation: The air supply controls the opening and closing. For more precise control, a double-acting valve can be combined with a spring return, as per customer requirements.

Parameter Teknikal Badan Injap

| Actuator material | Stainless steel or PolyamidePA | Bahan badan | SS304, 316, 316L |

| Seat material | PTFE, F46 | Bahan batang | SS304, 316, 316L |

| Ambient temp | -30℃~180℃ | Tekanan | 0~1.6MPa |

| Jenis Sambungan | Welding, flange, thread, clamp | Control type | Single-acting, double-acting |

| Applicable medium | Water, natural gas or liquid alcohol, oil, organic solvent, steam | Aksesori pilihan | Solenoid valve, limit switch box, positioner, etc |

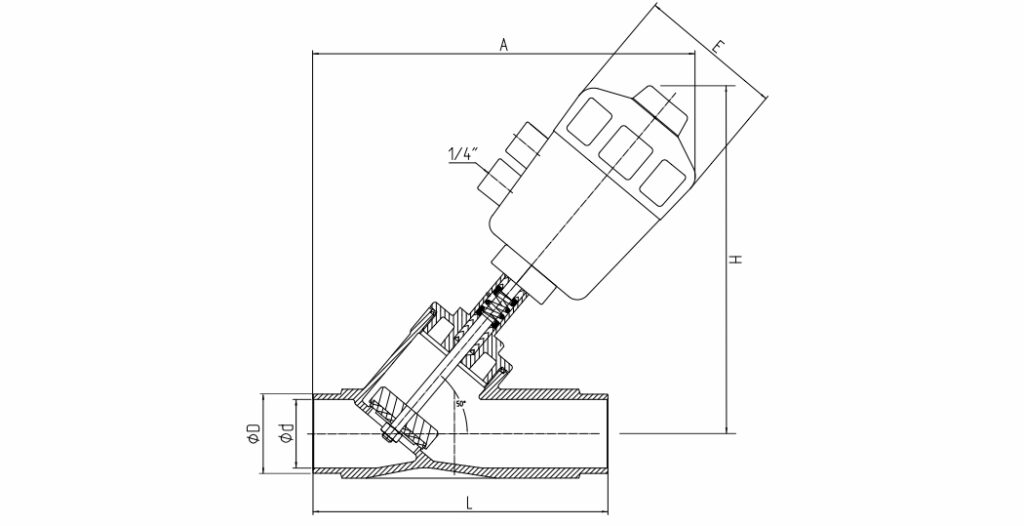

Welded Angle Seat Valve

| Size | Inch | d | D | L | H | A | E | Actuatar |

| DN15 | 1/2″ | 15.5 | 19.5 | 100 | 137 | 175 | 64 | 50 |

| DN20 | 3/4″ | 21.5 | 26.5 | 120 | 145 | 180 | 64 | 50 |

| DN25 | 1″ | 28.5 | 32.5 | 140 | 185 | 215 | 80 | 63 |

| DN32 | 1-1/4″ | 33 | 38.5 | 155 | 210 | 235 | 80 | 63 |

| DN40 | 1-1/2″ | 46 | 52 | 170 | 260 | 245 | 80 | 63 |

| DN50 | 2″ | 57 | 64 | 190 | 300 | 325 | 100 | 80 |

| DN65 | 2-1/2″ | 68 | 77 | 200 | 340 | 355 | 100 | 80 |

| DN80 | 3″ | 82 | 92 | 220 | 385 | 400 | 126 | 100 |

Dapatkan Sebut Harga Pantas

SYOR

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Injap Solenoid yang dikendalikan oleh Juruterbang Baca lagi

Edit Kandungan

Edit Kandungan

Dapatkan Sebut Harga Pantas

SYOR

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Injap Solenoid yang dikendalikan oleh Juruterbang Baca lagi