เราไม่เพียงแต่ให้ใบเสนอราคาแบบง่าย ๆ แต่เรายังเป็นผู้เชี่ยวชาญด้านการคัดเลือก การคำนวณ และการวาดภาพอีกด้วย

ข้อมูลการติดต่อ

- +86 -1598-9602972

- สอบถามข้อมูลเพิ่มเติมได้ที่@delcofluid.com

- ถนนหว่านเจียง เมืองตงกวน ประเทศจีน

ตัวเลือกยอดนิยม

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

โซลินอยด์วาล์วควบคุมด้วยนักบิน อ่านเพิ่ม

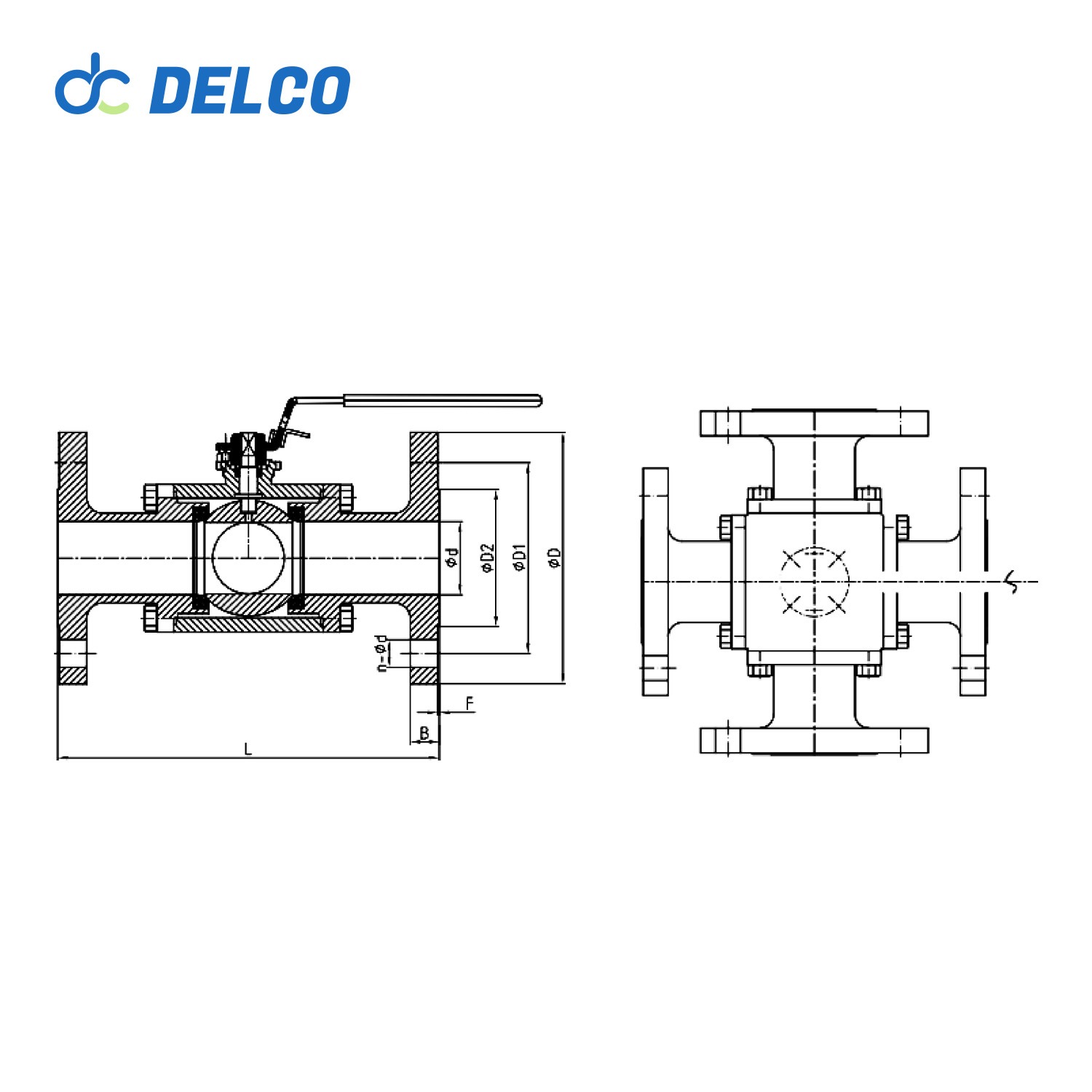

DELCO Valve Stainless Steel 4 Way Flange pneumatic Ball Valves

The integrated design of the four-way flange pneumatic ball valve not only enhances its aesthetic appeal but also contributes to its lightweight and user-friendly nature. With its swift disassembly and assembly process, this valve ensures operational efficiency while delivering outstanding performance. Its simplicity in configuration and generous flow capacity make it an ideal choice across various industrial sectors, including food, environmental protection, light industry, petroleum, papermaking, chemicals, and electric power. Renowned for its versatility and reliability, this valve plays a crucial role in the automation systems of these industries, facilitating seamless operations and maintaining high standards of performance.

แบบอย่าง: DK66-4TF

ช่วงขนาด: 1″ to 6″

ช่วงความดัน: 1.6 to 6.4MPa

วัสดุ: สแตนเลส 304/316

รับใบเสนอราคาทันที

ซัพพลายเออร์ที่ดีไม่เพียงแต่ทำให้คุณหมดกังวลเท่านั้น แต่ยังช่วยให้ธุรกิจของคุณพัฒนาอย่างยั่งยืนและทำให้แบรนด์ของคุณได้รับชื่อเสียงด้านการบริการและคุณภาพอย่างต่อเนื่องอีกด้วย

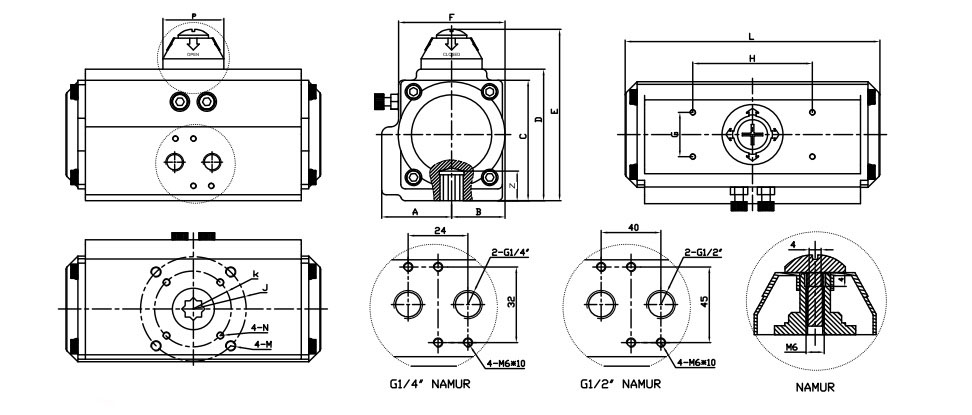

DELCO 4 Way Flange Pneumatic Actuator Ball Valve

พารามิเตอร์ทางเทคนิคของตัวกระตุ้นวาล์ว

| การแสดงสองแบบ | อากาศเปิด อากาศปิด ซัพพลายเออร์อากาศล้มเหลวในการรักษาตำแหน่งปัจจุบัน |

| N/C แบบแสดงเดี่ยว | อากาศเปิด, อากาศขัดข้องปิด, อากาศปิดไม่ได้ |

| การแสดงเดี่ยว N/O | อากาศปิด, อากาศขัดข้องเพื่อเปิด, อากาศเปิดไม่ได้ |

| อุปกรณ์เสริม | โซลินอยด์วาล์วกลับด้าน, กล่องสวิตช์จำกัด, วาล์วลดตัวกรองอากาศ, ตัวกำหนดตำแหน่ง, มือจับแบบแมนนวล, วาล์วล็อค |

พารามิเตอร์ทางเทคนิคของตัววาล์ว

| Body | ส่วนประกอบของวาล์ว | ||

| ช่วงขนาด | DN25~DN150 | วัสดุปิดผนึก | PTFE, PPL |

| Body material | SS304, SS316, SS316L | Core material | สแตนเลส |

| End conection | หน้าแปลน | Stem material | สแตนเลส |

| Operating pressure | 1.6 to 6.4MPa |

สื่อที่สามารถนำไปใช้ได้ | Water, air, oil, gas, etc |

| โครงสร้าง | แกนลูกบอลลอย | ||

โปรเซสเซอร์แหล่งอากาศ: ผสมผสานฟังก์ชันการกรอง การลดแรงดัน และการหล่อลื่น ช่วยให้แรงดันทางออกคงที่ มีให้เลือกทั้งแบบ 2 ชิ้นสำหรับการกรองอากาศอัดของเครื่องมือ และแบบ 3 ชิ้นเพื่อการหล่อลื่นเพิ่มเติม

โซลินอยด์วาล์วลม: ควบคุมการเปิดและปิดวาล์วลมด้วยการสร้างแม่เหล็กและขจัดแม่เหล็กเพื่อควบคุมการไหลของก๊าซตามสัญญาณแรงดันไฟฟ้า ให้การควบคุมการทำงานของวาล์วที่แม่นยำ มักใช้ในการจัดการแหล่งก๊าซและการไหลของวงจร

สวิตซ์จำกัด: ตรวจจับสถานะของวาล์วและส่งสัญญาณสำหรับตำแหน่งเปิดหรือปิด มีความสำคัญในระบบควบคุมอัตโนมัติ โดยยืนยันและดำเนินการตามโปรแกรมที่ตามมา ให้การป้องกันการล็อกวาล์ว และระบุสัญญาณเตือนระยะไกลภายในระบบ

ตำแหน่งวาล์ว: มีความสำคัญสำหรับการควบคุมที่แม่นยำเกี่ยวกับตำแหน่งวาล์วในวาล์วควบคุมลม โดยเปรียบเทียบการเคลื่อนที่ของก้านวาล์วและสัญญาณเอาต์พุตของตัวควบคุม และปรับสัญญาณเอาต์พุตของตัวกระตุ้นให้เหมาะสม

อุปกรณ์คู่มือ: เสริมชุดตัวกระตุ้นนิวเมติกส์ ช่วยให้ควบคุมวาล์วปีกผีเสื้อและวาล์วลูกบอลที่มีช่องเปิด 90° ด้วยมือหรือด้วยลมได้สะดวก ช่วยให้ควบคุมวาล์วได้หลากหลายและยืดหยุ่น ทั้งยังควบคุมด้วยมือและอัตโนมัติตามต้องการ

รับใบเสนอราคาอย่างรวดเร็ว

แนะนำ

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

โซลินอยด์วาล์วควบคุมด้วยนักบิน อ่านเพิ่ม

รับใบเสนอราคาอย่างรวดเร็ว

แนะนำ

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

โซลินอยด์วาล์วควบคุมด้วยนักบิน อ่านเพิ่ม