AUTOMATION VALVE Manufacturer since 2005

Electric Actuated Valve | Pneumatic Actuated Valve | Flow Control Valve | Solenoid Valve | Marine Valve | Manual Operated Valve etc.

MULTIPLE TYPES OF AUTOMATION VALVE

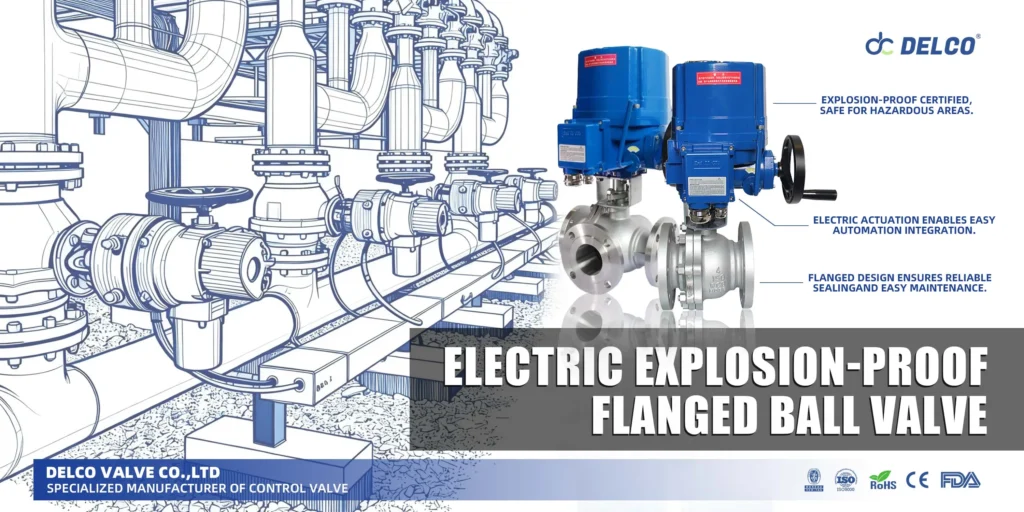

Electric Actuated Valve

DELCO Offering Multiple types of Electric Ball Valves | Butterfly Valves | Gate Valves | Globe Valves

Electric Actuated Valve

- Phone:+86-159 8960 2972

- Email:[email protected]

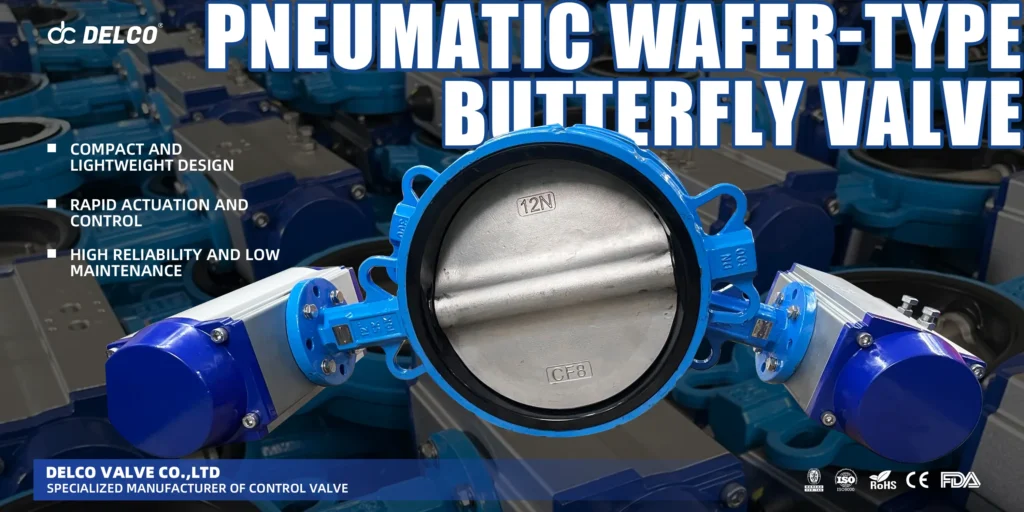

Pneumatic Actauted Valve

DELCO Offering Different types of Air Operated Ball Valve | Butterfly Valve | Gate Valve | Globe Valve

Pneumatic Actauted Valve

- Phone:+86-159 8960 2972

- Email:[email protected]

Globe Control Valve

DELCO Provide Pneumatic & Eletcric Globe Flow Control Valve | Pressure Control Valve | Temperature Control Valves

Globe Control Valve

- Phone:+86-159 8960 2972

- Email:[email protected]

Elektromagnetický ventil

DELCO Supply Direct Acting Solenoid Valve | Pilot Piston Solenoid Valve | Sanitary Solenoid Valve | Steam& Water Solenoid Valves

Elektromagnetický ventil

- Phone:+86-159 8960 2972

- Email:[email protected]

Electric & Pneumatic Actuator

Quarter-Turn Electric Actuator | Multi-turn Electric Actuator | AT & AW Series Pneumatic ACtuator

Electric & Pneumatic Actuator

- Phone:+86-159 8960 2972

- Email:[email protected]

Ruční ventil

Ball Valve | Butterfly Valve | Gate&Globe Valve | PRV | Safety Valve | Check Valve | Filter

Ruční ventil

- Phone:+86-159 8960 2972

- Email:[email protected]

GLOBAL PROJECT & INSTALLATION CASE

DELCO Valves are indispensable components in a wide range of industies, like Oil&Gas.Water & Wastewater Treatment.Power Generation,Chemical & Perochemical.Phamaceutical & Food.Marine & Shipbuiding.HVAC etc.

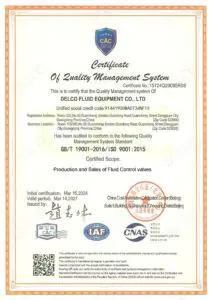

CERTIFICATES WORTH YOUR TRUST

DELCO have been certified by lS09001:2015, CE, SGS, ROHS, TUV, FDA andgained more than 30 patents to prove our professionalism in valve filed.We have won the trust of many customers with our high quality valves and services.

COOPERATIVE BRANDS WITH DELCO

LATEST BLOG & INFORMATION

FAQs

How do I select the most suitable valve for my project? What key factors should be considered?

Selecting the perfect valve for your project requires a systematic evaluation of four key dimensions:

Operating Conditions: This is the foundation. You need to define the media type (liquid, gas, steam, or if it contains particulates or is corrosive), temperature range, and pressure rating. For instance, a high-temperature, high-pressure steam system might require a forged steel gate or globe valve, while corrosive chemical media would best be handled by a PFA-lined or a 316L stainless steel ball valve.

Functional Requirements: What function does the valve need to perform? Is it for frequent, quick shut-off (we recommend a ball valve or butterfly valve), precise flow control (a V-port ball valve or a dedicated regulační ventil is ideal), or simply to prevent backflow (a check valve).

Industry Standards & Certifications: Different industries have different regulations. The oil and gas industry typically requires valves to comply with API standards, while the food and pharmaceutical industries need valves that meet sanitary standards (e.g., 3-A, FDA). Our entire product line is manufactured in strict accordance with relevant industry standards, and we can provide complete certification documents.

Cost & Maintenance: While ensuring the valve meets all operational requirements, we also help you balance the initial procurement cost with long-term operational and maintenance expenses.

Our Advantage: Don’t worry about the complexity of selection! Simply provide us with your operating parameters, and our experienced team of engineers will promptly offer a free, professional selection proposal to ensure you get the most cost-effective valve solution.

Should I choose a high-performance butterfly valve or a floating ball valve? What are their respective advantages?

That’s an excellent question, as both are widely used valves. The choice depends on your budget and specific application:

Floating Ball Valve:

Advantages: Offers excellent sealing performance, easily achieving bi-directional zero-leakage, and has strong high-pressure resistance. It provides minimal flow resistance and requires low torque for quick operation, making it the top choice for shut-off applications in most industries.

Best For: Applications with stringent sealing requirements, such as in the oil, natural gas, and chemical industries.

High-Performance Butterfly Valve (Double/Triple Offset):

Advantages: Compared to a ball valve of the same size, it is more compact, lighter, and more cost-effective, especially in large-diameter pipelines. A triple-offset design creates a frictionless open/close action, significantly extending seat life while still achieving a high level of sealing.

Best For: Water treatment, power generation, HVAC, and some applications requiring flow control.

Our Advantage: Whether you need a high-pressure ball valve or a large-diameter high-performance butterfly valve, we maintain a substantial inventory and a robust supply chain to ensure fast delivery. We can also provide a detailed performance and cost comparison to help you make the best decision.

Do you offer custom valve solutions for special applications?

Absolutely. Non-standard customization is one of our core competencies. We understand that standard products cannot meet every unique operational challenge. Our technical team excels at handling a wide range of complex requirements, including:

Special Materials: Alloys such as Hastelloy, Monel, and Titanium for extremely corrosive media.

Structural Modifications: Stem extensions (for insulation or underground pipelines), special end connections, multi-port designs, and more.

Specialized Conditions: Custom designs for ultra-high temperatures, cryogenic applications, and media with high abrasive particles.

Automation Integration: Integrating specific brands or functions of actuators and accessories according to your control requirements.

Our Advantage: Simply send us your technical specifications. Our engineers will work with you one-on-one, providing a complete customized solution from design and material selection to manufacturing, including detailed drawings to ensure the product 100% meets your site requirements.

What should I consider when selecting an actuator for valve automation?

Choosing the right actuator is critical for achieving reliable automated control. You need to consider the following:

Torque/Thrust Output: The actuator’s output torque must be greater than the torque required to operate the valve, with a sufficient safety margin (typically 1.3-1.5 times).

Power Source: Select pneumatic, electric, or hydraulic based on site conditions. Pneumatic actuators offer fast response times and are inherently explosion-proof. Electric actuators provide precise control and are easy to integrate with PLC systems.

Control Type: Is it for simple on/off service, or is it a modulating type that requires a feedback signal (e.g., a 4-20mA input/output)?

Environmental Factors: Consider the ambient temperature, humidity, ingress protection (IP rating), and whether an explosion-proof rating (Ex rating) is necessary.

Our Advantage: We offer one-stop valve automation services. You don’t need to source valves and actuators separately. We can assemble, calibrate, and test the complete package before shipping, ensuring you receive a unit that is ready for immediate installation, saving you significant time and cost on-site.

What is a valve's Cv, and how does it affect my system's flow rate?

The Cv, or Flow Coefficient, is a critical metric that measures a valve’s flow capacity. It is defined as the number of US gallons per minute (GPM) of 60°F water that will pass through a valve with a pressure drop of 1 psi. In simple terms, the higher the Cv value, the smaller the resistance to flow, and the greater the valve’s capacity.

Accurately calculating the required Cv is crucial during selection, especially for control valves. If the Cv is too small, the valve won’t be able to pass the maximum flow required by the system. If it’s too large, the valve may only need to open slightly to achieve the desired flow rate, leading to poor control accuracy and potential system instability.

Our Advantage: Based on your provided parameters like flow rate and pressure, we can perform a professional Cv calculation for you free of charge and recommend the most suitable valve size and model to ensure your control system operates with stability and efficiency.

How can I perform routine valve maintenance to extend its service life?

Proper maintenance can significantly extend a valve’s life and ensure system safety. We recommend the following practices:

Regular Cleaning: Keep the valve exterior clean, removing dust, grease, and debris, especially around the stem.

Lubrication: Periodically apply lubricant to transmission parts such as the stem threads and gearbox to ensure smooth operation.

Seal Inspection: Regularly check for any signs of internal or external leakage. For packing seals, the gland bolts can be gently tightened; if leakage persists, the packing should be replaced. For flange connections, check for loose bolts.

Regular Operation: For valves not frequently used, it is advisable to cycle them (fully open and fully close) periodically to prevent the disc or ball from seizing.

Our Advantage: We provide not only high-quality valves but also full life-cycle after-sales support. If you encounter any maintenance challenges or need spare parts (like O-rings, gaskets, or packing), our support team will respond quickly to provide professional guidance or components.

What quality assurances and certifications do your valves have?

Quality is the foundation of the trust we build with our clients. We have established a strict quality control system to ensure every valve leaving our factory meets the highest standards:

System Certification: We are an ISO 9001 certified company for quality management.

Product Certifications: Our main product lines have obtained relevant authoritative certifications for their target markets, including CE Marking (for EU market access) and RoHs compliance.

Quality Control: We implement 100% inspection at every critical stage—from Positive Material Identification (PMI) for incoming raw materials, to dimensional checks during machining, to pressure testing (both shell and seat tests) for the final product.

Our Advantage: We can provide a detailed Material Test Report (MTR) and a factory test report for every shipment. Choosing us means you are choosing a partner committed to reliability, quality, and compliance.

What is the process for ordering valves, and what is your typical lead time?

We are committed to providing you with a simple and efficient procurement experience. The process is as follows:

Inquiry: Contact us with your requirements via phone, email, or our website’s contact form.

Solution & Quotation: Our sales engineers will connect with you to confirm technical specifications and provide a formal quotation and technical proposal.

Order & Production: Once the contract is signed, your order is immediately entered into our production planning system.

Delivery & Logistics: After production and testing are complete, we will arrange reliable logistics to deliver the goods safely to your designated location.

Our Advantage: “Fast delivery” is one of our core commitments. Thanks to our optimized production processes and robust supply chain management, we keep many standard products in stock for rapid dispatch. Even for customized orders, we offer lead times that are significantly better than the industry average. Feel free to ask our sales team for real-time stock status and estimated delivery times for specific models.