BLOG

DELCO Valve Provide Various Optimal Solution For Industrial Valves, Especially For Control Valves.

TAGS

Contact Us

7 Types of Flow Control Valves for Precise Selection

- DELCO Valve

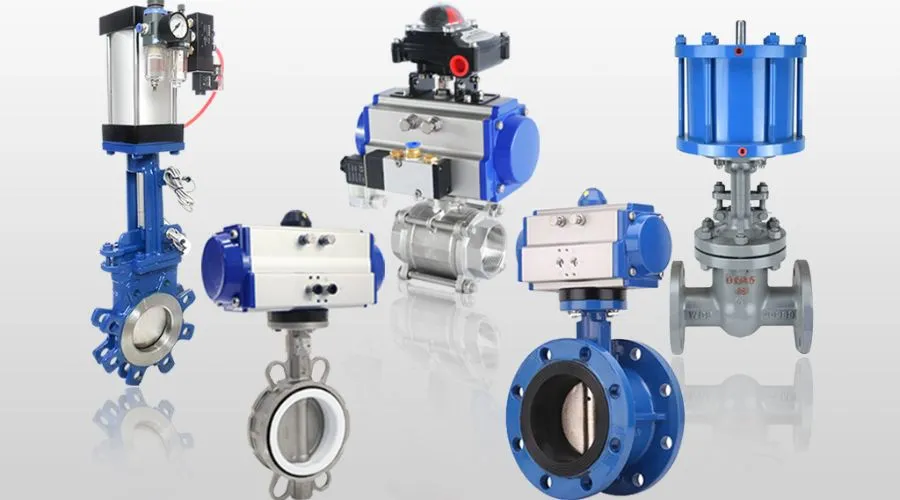

Choosing the right valve is crucial for any industrial fluid control system. An appropriate valve not only ensures stable production but also helps save costs and enhance automation. But with so many types of flow control valves available, do you ever feel overwhelmed?

As experts in fluid control, we offer a one-stop solution. This article will provide an in-depth analysis of our main industrial valve types, helping you understand the working principles, application scenarios, and unique advantages of each, so you can make the most informed decision when selecting your equipment.

1. The Future of Precision and Intelligence: Motorized Valve Series

Motorized valves are the ideal choice for industrial automation and remote control. Driven by an electric actuator, they can accurately control fluid flow, making them perfect for applications requiring high precision, remote operation, or automated integration.

Our motorized valve series includes:

Motorized Ball Valve: Simple in structure with excellent sealing and high flow capacity. It’s especially suitable for quick on/off and fluid cutoff, making it a common choice for industrial pipelines.

Applications: Inlet/outlet water control in water treatment plants, temperature regulation in HVAC systems, and pipeline switching in the food and beverage industry.

Motorized Butterfly Valve: Compact and lightweight, ideal for large-diameter pipelines. It offers low flow resistance and fast switching.

- Applications: Large-scale water conservancy projects, fluid control in chemical manufacturing, and gas regulation in industrial ventilation systems.

The Three Types of Electric Actuators

The electric actuator is the “brain” of the motorized valve. We offer three types to meet different control needs:

- On-off type: The most basic type, used to fully open or close the valve for simple fluid on/off control.

- Regulating type: Can precisely adjust the valve’s opening based on a received signal (e.g., 4-20mA current) for fine flow control.

- Intelligent Type with display screen: Equipped with a display screen and a built-in intelligent control module. This powerful actuator supports remote diagnostics, parameter settings, and fault alarms, making it ideal for advanced automation.

2. High Efficiency and Reliability: Pneumatic Valve Series

Pneumatic valves are powered by compressed air, offering fast response times and high reliability. In hazardous environments like those with flammable or explosive materials, pneumatic valves are the preferred choice due to their non-electrical operation.

Our pneumatic valve series includes:

- Pneumatic Ball Valve: Similar to the motorized ball valve but uses an air source for faster switching.

- Applications: Material conveying on automated production lines, rapid pipeline switching in the chemical and pharmaceutical industries.

- Pneumatic Butterfly Valve: Compact and well-suited for applications that require fast and frequent operation.

- Applications: Pipeline control in beer brewing and sugar manufacturing, and environmental projects like flue gas desulfurization.

- Pneumatic Angle Seat Valve: Features a Y-shaped body with minimal flow resistance and high flow capacity. It offers fast switching and a long service life.

- Applications: Steam systems, sterilization equipment, and precise control in textile printing and dyeing machinery.

The Two Operating Modes of Pneumatic Actuators

The pneumatic actuator is the core of the pneumatic valve, primarily coming in two types:

- Single-acting: The valve opens with an air supply and closes automatically with a spring return. This design automatically returns to a safe position if the air supply is cut off.

- Double-acting: The valve opens with an air supply and also closes with an air supply. It provides greater torque for larger-diameter or high-pressure valves.

3. Experts in Rapid Response: Solenoid Valve Series

Solenoid valves are automated components that use electromagnetic force to drive the valve core directly or indirectly. They are known for their quick response, small size, and easy installation.

We offer several types to meet different fluid and pressure requirements:

- Direct Acting Diaphragm Solenoid Valve: Works without a pressure differential, suitable for low flow and low-pressure applications.

- Applications: Small water treatment devices, garden irrigation, and commercial or household appliances like coffee machines.

- Pilot Type Solenoid Valve: Uses the fluid’s own pressure differential to drive the valve, making it ideal for large-flow and high-pressure systems.

- Applications: Gas control for large industrial furnaces and flow control for tap water pipelines.

- Piston Type Solenoid Valve: Features a piston structure that can withstand higher pressure.

- Applications: High-temperature steam pipelines and high-pressure fluid systems.

4. Precise Fluid Management: Control Valve Series

Control valves are key devices for achieving precise control of flow, pressure, and temperature.

- Pneumatic Control Valve: Offers a fast response and high control accuracy.

- Applications: Temperature and pressure control in chemical reactors, and distillation column regulation in oil refineries.

- Electric Control Valve: Provides even higher control accuracy and is highly programmable.

- Applications: Feedwater regulation in thermal power plants, and precise mixing systems in the pharmaceutical industry.

- Self-Operated Pressure Control Valve: Operates without an external power source, relying on the fluid’s pressure changes for regulation.

- Applications: Steam pressure reduction in industrial boilers, and pressure stabilization in compressed air stations.

5. Other Important Valve Types

In addition to our main product lines, we also offer a variety of functional valves to complete your fluid control system:

- Check Valve: Ensures one-way fluid flow, preventing backflow.

- Safety Valve: Automatically opens when system pressure exceeds a set value to protect equipment.

- Y-Strainer: Removes solid impurities from the fluid, protecting downstream equipment from damage.

- Pressure Reducing Valve (PRV): Lowers high upstream fluid pressure to a desired low downstream pressure.

6. How to Select the Right Flow Control Valve?

Choosing the right flow control valve is the first step to ensuring a stable system. Use the following key parameters to quickly match the most suitable valve for your needs:

| Parameter | Description |

| Medium | Fluid type (water, oil, gas, steam, etc.) and its corrosiveness |

| Pressure & Temperature | The system’s maximum working pressure and temperature |

| Size & Connection End | Pipeline diameter and connection type (threaded, flanged, welded, etc.) |

| Control Requirements | Do you need simple on/off, precise regulation, or intelligent control? |

| Working Environment | Are there specific requirements for flammable, explosive, or other conditions? |

We offer a diverse range of products and can provide professional, customized solutions based on your specific needs. If you have any further questions about valve selection, please feel free to contact our team of experts. We are here to help.