We don’t just provide simple quotations, but we are experts in selection, calculation and drawing.

Top Picks

-

Electric Sanitary Clamp Butterfly Valve | For Food, Beverage & Pharmaceutical

Electric Butterfly Valve Read more -

Electric Wafer Butterfly Valve | Ductile Iron Valve for Industrial & HVAC Applications

Electric Butterfly Valve Read more -

3-Piece Socket Weld Ball Valve | High-Pressure Electric Actuated Valve

Electric Ball Valve Read more -

PTFE-Lined Flanged Ball Valve | Electric Actuated for Corrosive Service

Electric Ball Valve Read more

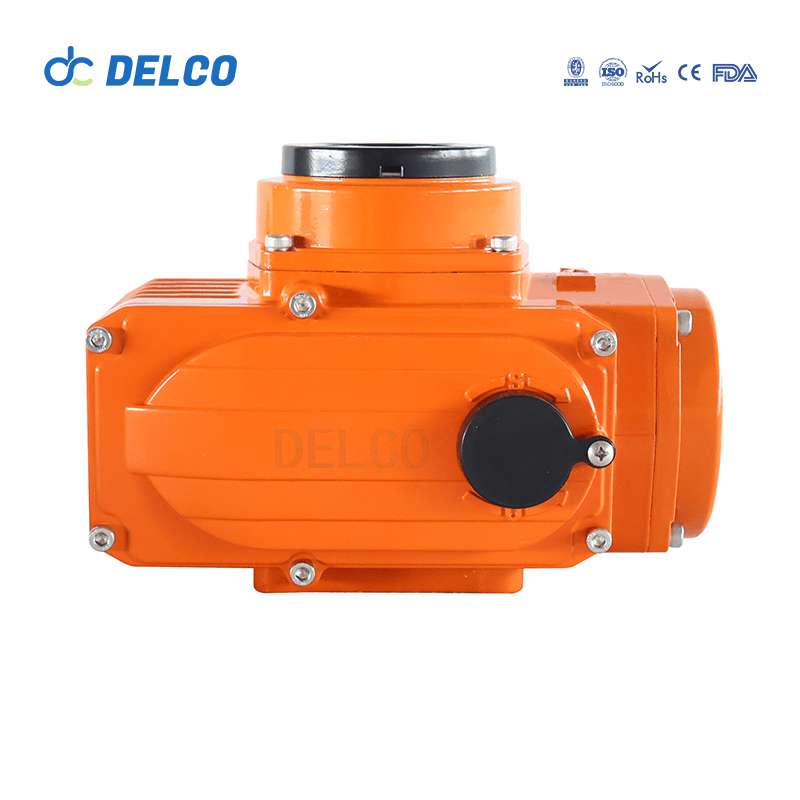

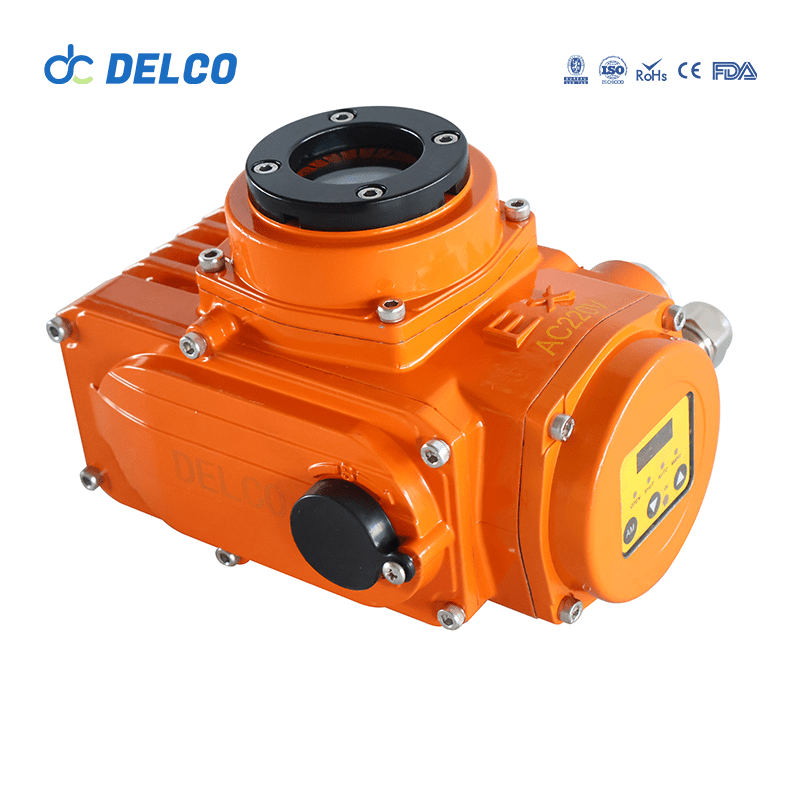

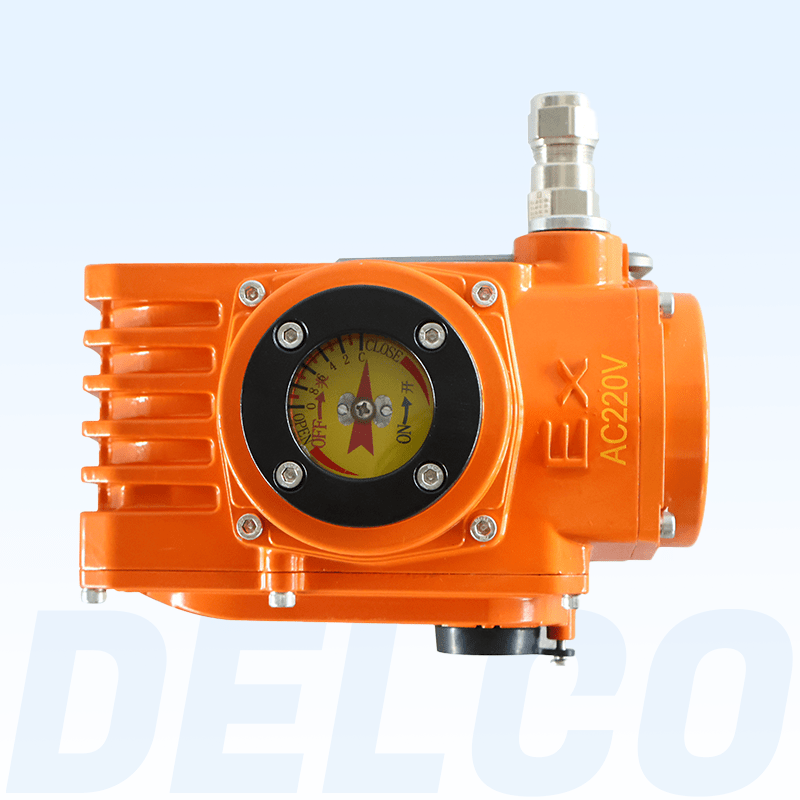

DELCO DKS IP67 Explosion-proof Electric Valve Actuator

DELCO’s latest electric actuators showcase corrosion-resistant aluminum housings, high torque capabilities, manual operation choices with handles, superior IP67-rated sealing (with optional IP68), and self-locking functionality, enhancing both safety and reliability.

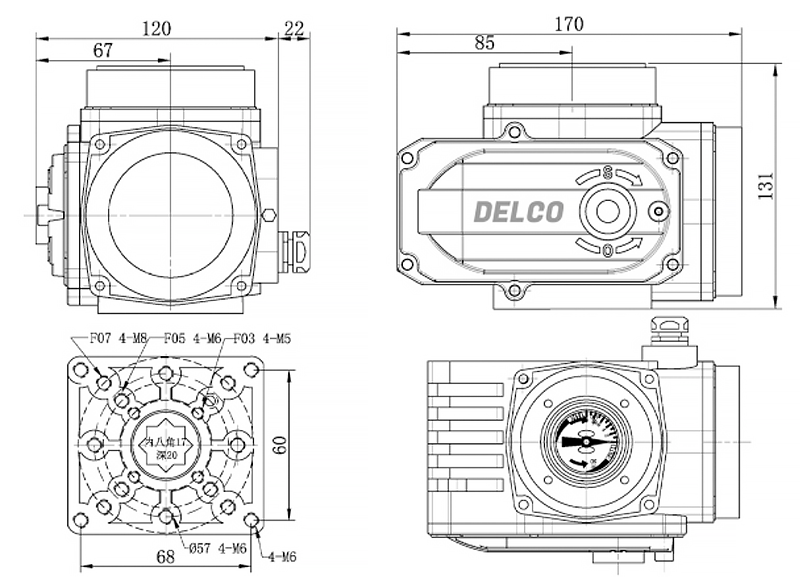

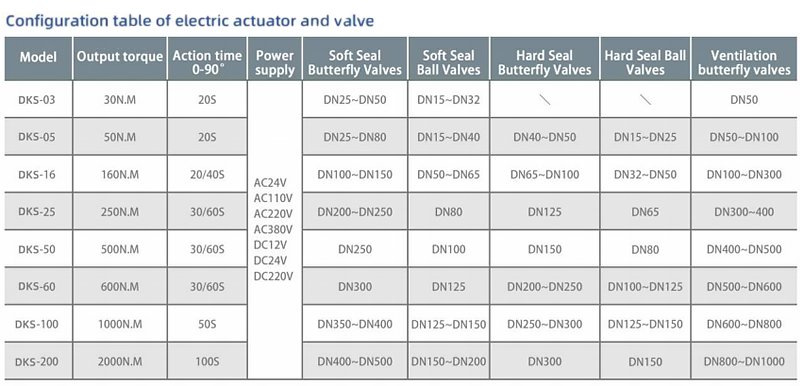

Model: DKS electric actuator

Action Time: 20S to 100S

Torque Output: 30-2000Nm

Material: Aluminum Alloy

Item | DELCO DKS IP67 Explosion-proof Electric Valve Actuator | ||

Shell Material | Die-Cast Aluminum Alloy (Powder Coated) | ||

Lifespan | 100,000 (Ten Thousand) Times | ||

Output Torque | 50 to 4000Nm | ||

Angle of Rotation | 90° ±4° | ||

90° Cycle Time | 15S/30S/60S | ||

Optional Voltage | DC24V (±10%), AC110-220V, 50/60Hz | ||

Insulation Resistance | DC24V: 100MΩ/250V; AC110/220V/380V: 100MΩ/500V | ||

Withstand Voltage | DC24V: 500V; AC110/220V: 1500V; AC380V: 1800V 1Minute | ||

Protection Class | IP67 IP68 | ||

Explosion Proof | EX d II BT4 | ||

Optional Accessories | Over Torque Protectors, Dehumidify Heater, Stainless Steel Coupling & Yoke | ||

Ambient Temp. | Range from -30°C to +60°C (For Use In Temperatures Below 0°C, We Suggest Anti-Condensate Elements) | ||

DELCO DKS Electric Actuators: Precision, Durability, and Innovation

DELCO Valve is proud to introduce the DELCO DKS Electric Actuators, a product designed to provide precise, reliable, and efficient valve control across a wide range of industrial applications. These actuators are designed to move valves from 0° to 90° with high accuracy, ensuring smooth and reliable operation in automated control systems.

1. What are DELCO DKS Electric Actuators?

The DELCO DKS Electric Actuators are electric devices used to control the movement of valves in automated systems. These actuators are commonly used in various industrial applications where accurate and automated valve control is required. They are powered by 380V/220V/110V AC or 24V/110V DC, with control signals such as 4-20mA current or 0-10V DC voltage to adjust the valve to the desired position.

The DKS Series Electric Actuators are designed for rotating valves like butterfly valves, air doors, baffle valves, and cock valves. These actuators can handle a wide range of applications across industries such as petroleum, chemical processing, water treatment, power plants, and more.

2. Advantages of DELCO DKS Electric Actuators

DELCO DKS Electric Actuators offer a number of advantages that make them stand out in the industry:

2.1 Corrosion Resistance

The shell of the actuator is made of hard aluminum alloy, which undergoes anodizing and polyester powder coating processes. This ensures that the actuators have strong resistance to corrosion, making them suitable for use in harsh environments, including those with exposure to water or chemicals.

2.2 Compact Design with High Torque

The actuators are equipped with a fully enclosed squirrel cage motor that offers high torque in a small size. This design reduces inertia and enables the actuator to deliver high performance in a compact form factor. This makes it ideal for space-constrained installations while maintaining power and reliability.

2.3 Self-Locking Mechanism

The DELCO DKS Electric Actuators use a precision twin-turbine worm mechanism, which efficiently transmits large torque while maintaining high efficiency and low noise levels (max. 50 dB). The self-locking feature prevents reverse rotation, ensuring that the actuator’s position remains stable and reliable without the need for additional external locking mechanisms.

2.4 Manual Operation Capability

For added convenience and safety, the DELCO DKS Electric Actuators are equipped with a manual operation feature. When the actuator is not energized, it can still be operated manually using a wrench handle. This feature ensures that the actuator can still be adjusted in case of power failure or maintenance.

2.5 Integrated Intelligent Control

The DELCO DKS Electric Actuators come with an integrated intelligent control module that allows for efficient and accurate positioning. This eliminates the need for external positioners, simplifying the setup and reducing the complexity of the system. The actuators can also support different types of control signals, such as switching, regulating, and intelligent integration.

3. Applications of DELCO DKS Electric Actuators

The DELCO DKS Electric Actuators are highly versatile and are used in various applications, including but not limited to:

3.1 Petroleum Industry

In the petroleum industry, these actuators are used for controlling the flow of fluids in pipelines, storage tanks, and processing systems. The precise valve control ensures efficient and safe operations in critical oil and gas production processes.

3.2 Chemical Processing

Chemical plants use DELCO DKS Electric Actuators to control the flow of chemicals, gases, and other fluids. The actuators’ high accuracy ensures that the correct quantities of chemicals are used in processing, improving efficiency and safety.

3.3 Water Treatment

Water treatment plants rely on these actuators to manage the flow of water and chemicals in filtration and treatment processes. With precise control over valve positions, the DELCO DKS Electric Actuators help optimize the efficiency of water treatment operations.

3.4 Power Generation

In power plants, these actuators are used to control the flow of steam, water, and fuel. The DELCO DKS Electric Actuators help maintain optimal operating conditions, ensuring efficient energy production and minimizing downtime.

3.5 HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, these actuators regulate the flow of air and water, ensuring comfortable and energy-efficient indoor environments.

4. Maintenance and Servicing of DELCO DKS Electric Actuators

Proper maintenance is essential to ensure the longevity and efficiency of DELCO DKS Electric Actuators. Here are some key maintenance tips:

4.1 Regular Inspections

Perform regular inspections of the actuator’s electrical components, including the motor and control system. This ensures that there are no signs of overheating or wear that could lead to failure.

4.2 Sealing and Protection

Check the seals regularly to maintain the IP67 (standard) or IP68 (optional) protection level. This ensures that no water or dust can enter the actuator, protecting the internal components from damage.

4.3 Lubrication

Lubricate the mechanical components to reduce friction and wear. This will help the actuator function smoothly and quietly, prolonging its service life and ensuring low noise levels.

4.4 Space Heater Function

Ensure the space heater inside the actuator is working correctly. The heater prevents condensation and keeps the internal components dry, which is particularly important in environments with significant temperature fluctuations.

5. Why Choose DELCO DKS Electric Actuators?

The DELCO DKS Electric Actuators are engineered to provide top-notch performance and reliability. Here’s why they should be your actuator of choice:

High performance with precise valve control for various industrial applications.

Durable design with strong corrosion resistance and self-locking features.

Energy-efficient operation that minimizes power consumption while maximizing output.

Safety and reliability with built-in overheat protection, dual limit switches, and manual operation capability.

Ease of integration with intelligent control and simplified installation processes.

By choosing DELCO DKS Electric Actuators, you are investing in a reliable, efficient, and durable solution for your industrial needs.

FAQs

What is the operating range of the DELCO DKS Electric Actuators?

What power sources are compatible with DELCO DKS Electric Actuators?

What makes DELCO DKS Electric Actuators suitable for harsh environments?

How do I manually operate DELCO DKS Electric Actuators?

What is the maintenance required for DELCO DKS Electric Actuators?

Get A Quick Quote

RECOMMEND

-

Electric Sanitary Clamp Butterfly Valve | For Food, Beverage & Pharmaceutical

Electric Butterfly Valve Read more -

Electric Wafer Butterfly Valve | Ductile Iron Valve for Industrial & HVAC Applications

Electric Butterfly Valve Read more -

3-Piece Socket Weld Ball Valve | High-Pressure Electric Actuated Valve

Electric Ball Valve Read more -

PTFE-Lined Flanged Ball Valve | Electric Actuated for Corrosive Service

Electric Ball Valve Read more

Get A Quick Quote

RECOMMEND

-

Electric Sanitary Clamp Butterfly Valve | For Food, Beverage & Pharmaceutical

Electric Butterfly Valve Read more -

Electric Wafer Butterfly Valve | Ductile Iron Valve for Industrial & HVAC Applications

Electric Butterfly Valve Read more -

3-Piece Socket Weld Ball Valve | High-Pressure Electric Actuated Valve

Electric Ball Valve Read more -

PTFE-Lined Flanged Ball Valve | Electric Actuated for Corrosive Service

Electric Ball Valve Read more