Home /

Home / Gate Valve Guide: Working Principles, Types & Uses (2026)

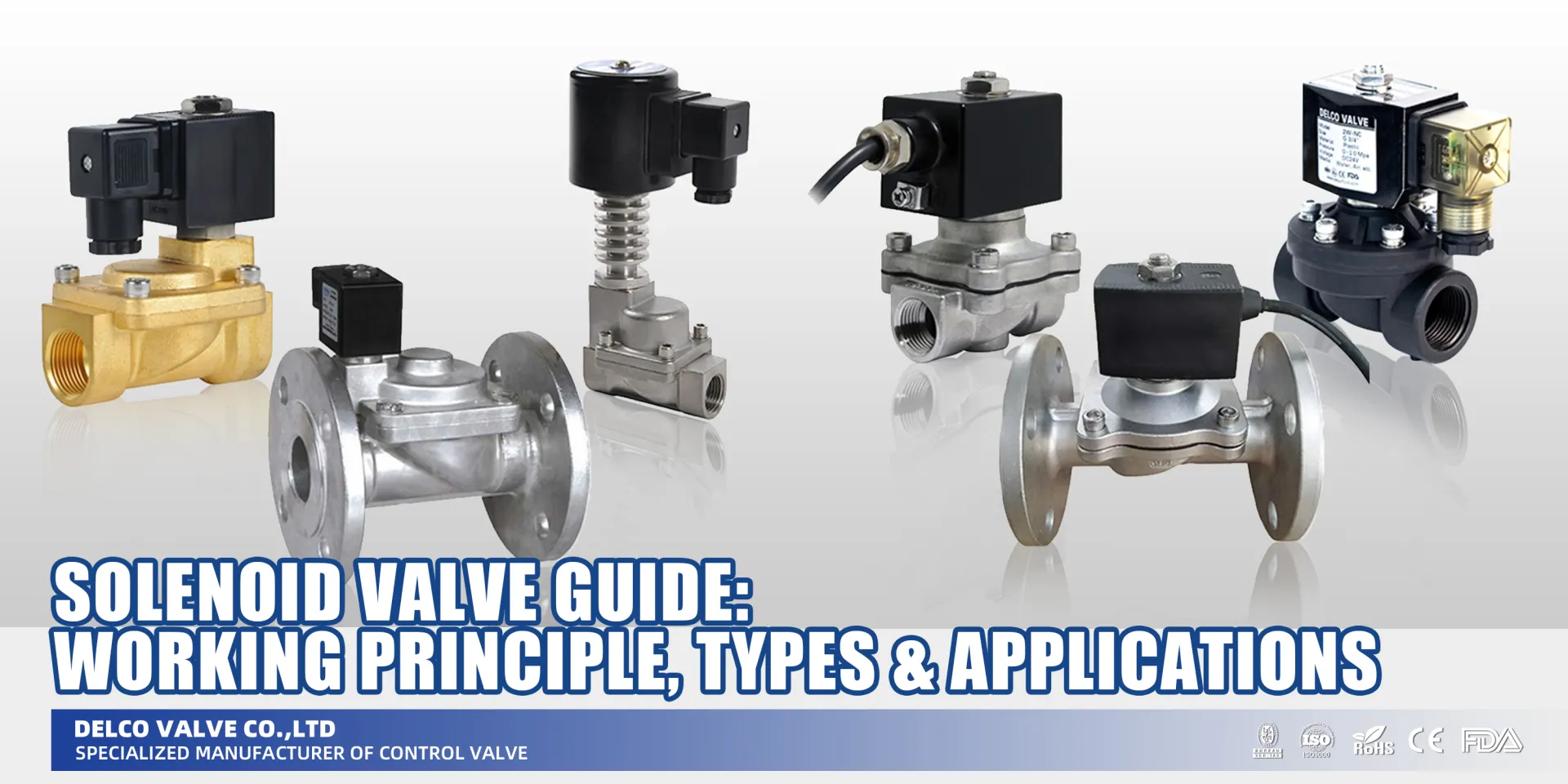

Solenoid Valve Guide: Working Principle, Types & Applications

Dec 30, 2025

Gate Valve Guide: Working Principles, Types & Uses (2026)

Dec 30, 2025

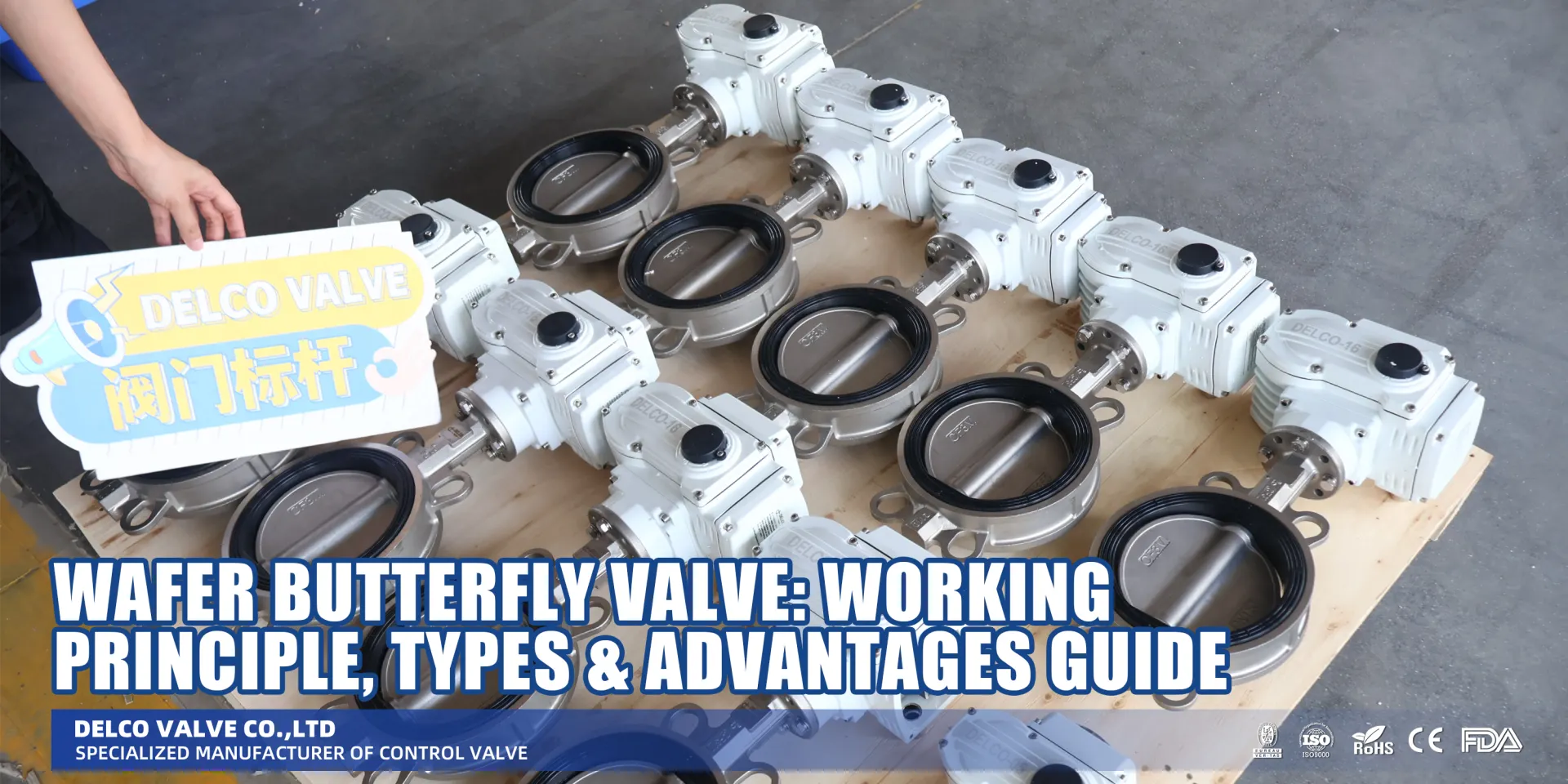

Wafer Butterfly Valve: Working Principle, Types & Advantages Guide

Dec 29, 2025

Motorized Ball Valve: The Complete Guide to Types, Wiring, and Selection

Dec 29, 2025

Master gate valve working principles types and uses. Discover wedge, rising stem, and knife designs for efficient industrial isolation.

How Gate Valves Work: The Fundamental Principles

Ever wonder what’s actually happening inside the pipeline when you crank that wheel? Unlike other flow control devices (see our complete guide on [What Is a Valve: Types, Parts, and Functions]), the gate valve is strictly designed for on/off isolation.

Simply put, these are the workhorses of the global isolation valve market. I often tell my clients to think of a gate valve like a medieval castle gate—it’s either all the way up to let everyone through, or all the way down to stop everything.

Here is the straightforward breakdown of the operation:

- Handwheel/Actuator Rotation: Being a multi-turn valve, you have to rotate the handle multiple times.

- Stem Movement: This rotation transfers energy to the valve stem.

- Gate Action: The stem physically lifts the rectangular or circular gate (the wedge) out of the path of the fluid or pushes it down to seal it.

Full-Open vs. Full-Closed Positions

The beauty of this design lies in its full bore capability. When the valve is fully open, the gate is completely retracted into the bonnet. This means the pipeline is virtually unobstructed, resulting in minimal flow resistance and a very low pressure drop. You aren’t fighting the fluid; you’re just opening the door.

Conversely, when fully closed, the gate wedges tightly between two seats, providing a robust shut-off. This design also allows for bi-directional flow, meaning it doesn’t matter which way the fluid is running—the valve will stop it from either direction.

The Throttling Misconception

Here is a major warning I give to everyone in the industry: Never use a gate valve for throttling.

It is tempting to leave the valve half-open to regulate flow, but these valves are designed strictly for on/off service. If you leave the gate partially open:

- Vibration: The high-velocity fluid hits the bottom of the gate, causing severe chatter and vibration.

- Erosion: The turbulent flow will quickly erode the disc and seats (wire drawing), destroying the seal.

If you need to regulate flow, use a globe valve. If you need isolation with zero obstruction, stick with the gate valve.

Next Step

Would you like me to detail the specific components that make this operation possible, like the difference between the bonnet and the body?

Key Components and Gate Valve Parts Name

To understand how these work, you need to know what’s going on under the hood. A gate valve isn’t overly complex, but every piece plays a specific role in maintaining that pressure boundary and ensuring a tight seal.

Here is the breakdown of the essential gate valve parts:

- Body: This is the main pressure-retaining part that connects to the pipeline. It houses the internal hardware and allows flow through the valve.

- Bonnet: Think of this as the cover for the body. It provides an opening to install the internal parts and is bolted or screwed onto the body to create a leak-proof seal.

- Gate (or Wedge): This is the heart of the valve. It’s the barrier that moves up and down to either allow full flow or stop it completely.

- Stem: The rod that connects the handwheel to the gate. When you turn the handle, the stem transfers that motion to lift or lower the wedge.

- Seats: These are the sealing surfaces inside the body where the gate rests when closed. High-quality seats are crucial for preventing internal leakage.

- Packing: Located around the stem, the packing acts as a gasket to prevent the fluid from leaking out of the valve along the stem area.

- Handwheel/Actuator: The manual wheel or automated motor used to operate the valve.

OS&Y Gate Valve Meaning

You will often see the term OS&Y (Outside Screw and Yoke) on specs, especially in fire protection and industrial applications in the US.

In an OS&Y gate valve, the threads of the stem are exposed outside the valve body. This provides a clear visual indication of the valve’s status: if the stem is sticking up, the valve is open; if it’s down, it’s closed. This design also keeps the threads out of the fluid, preventing corrosion from the media.

Next Step: Would you like me to create a comparison table for the different types of wedges (Solid vs. Flexible) for the next section?

Types of Gate Valves: Classification and Features

When you’re sourcing valves for a project, you quickly realize that “one size fits all” doesn’t apply here. We categorize gate valve types based on three main factors: the internal design of the wedge, how the stem operates, and the seating material. Making the right pick here determines whether your system runs smoothly or requires constant maintenance.

Classification by Wedge Design

The wedge is the part that actually stops the flow. Depending on pressure and temperature, I recommend specific designs:

- Solid Wedge: This is the most common and robust type. It is a single-piece construction, making it perfect for turbulent flow. It’s simple, strong, and generally the most cost-effective solid wedge vs flexible wedge option.

- Flexible Wedge: Unlike the solid type, this has a slight cut around the perimeter. Why? It allows the wedge to flex slightly. This is crucial in steam systems to prevent thermal binding—where heat expansion locks the valve shut.

- Split or Parallel Disc: Used primarily in high-pressure scenarios. The discs move independently to adjust to the seat, ensuring a tight seal even when the pipe undergoes thermal stress.

Rising Stem vs Non-Rising Stem

This classification is about space and visibility.

- Rising Stem Gate Valve (OS&Y): The stem physically rises out of the handle as you open it. This is a massive advantage for safety because you can see from a distance if the valve is open or closed. It’s the standard for fire protection systems, but it requires vertical clearance.

- Non-Rising Stem Gate Valve: The stem threads into the gate inside the valve body. The height doesn’t change during operation. I use these in tight spaces, like underground water distribution or inside compact manifold systems.

Seating and Specialized Variants

Beyond the standard setups, we have specialized designs for specific media:

- Resilient Seated Gate Valve: The wedge is encapsulated in rubber (usually EPDM). This allows for a “bubble-tight” seal, making it the industry standard for water and wastewater to prevent leakage.

- Knife Gate Valve: Designed with a sharp edge to cut through thick fluids. If you are dealing with paper pulp, slurry, or wastewater sludge, a standard wedge will get clogged; a knife gate valve is the only way to go.

- Slab Gate Valve (Through Conduit): Common in oil and gas pipelines. It features a single unit with a bore-sized hole. When open, it offers smooth flow with zero turbulence and is “piggable” for cleaning.

Quick Comparison of Gate Valve Types

Here is a breakdown to help you match the valve to the application:

| Valve Type | Best Application | Primary Advantage | Limitation |

|---|---|---|---|

| Solid Wedge | General industrial, Water, Oil | Robust and simple design | Can lock up due to thermal expansion |

| Flexible Wedge | Steam, High-temp systems | Resists thermal binding | Weaker in turbulent flow than solid |

| Rising Stem (OS&Y) | Fire protection, Critical isolation | Visual indication of position | Requires extra vertical space |

| Non-Rising Stem | Underground, Plumbing | Compact, space-saving | No visual open/close indication |

| Resilient Seated | Water, Wastewater | Bubble-tight shutoff | Temperature limited by rubber material |

| Knife Gate | Slurry, Pulp, Viscous fluids | Cuts through solids | Not suitable for high pressure |

Would you like me to detail the specific maintenance schedules required for resilient seated versus metal seated valves next?

Advantages and Limitations of Gate Valves

When we look at selecting the right valve for a pipeline, the Gate Valve is often the first choice for isolation applications, and for good reason. Understanding the pros and cons helps us avoid costly mistakes in the field.

Key Advantages: Why We Use Them

The primary benefit here is efficiency. Because these are full bore valves, the diameter of the opening matches the pipe.

- Low Pressure Drop: Since the gate lifts entirely out of the flow path, there is almost no flow resistance. This keeps your pumping efficiency high and energy costs low.

- Bi-directional Capability: Unlike a globe or check valve, a gate valve allows flow in either direction. You don’t have to worry about installation orientation regarding flow direction.

- Durable Sealing: Whether using a solid or flexible wedge, these provide a tight, metal-to-metal or resilient seal, making them reliable for long-term shut-off.

Limitations to Keep in Mind

While they are excellent for isolation, they aren’t a “do-it-all” solution.

- No Throttling: Never use a gate valve to regulate flow. Leaving it partially open causes vibration that destroys the seats and the wedge (wire drawing).

- Slow Operation: These are multi-turn valves. You have to rotate the handwheel many times to go from fully open to fully closed. This is actually a safety feature to prevent water hammer, but it makes them bad for quick-action needs.

- Thermal Binding: In high-temperature steam applications, the metal body can contract around the wedge as it cools, sometimes locking the valve shut.

Pro Tip: While gate valves isolate flow, they cannot prevent system overpressure. Always ensure you have dedicated [Safety Valves] installed in critical lines to protect your equipment from pressure spikes.

When to Choose Gate Valves

I recommend sticking to Gate Valves when your primary need is strictly On/Off service—what we call isolation. If you need to preserve fluid pressure and don’t require frequent cycling, this is your best bet. If you need to control the flow rate, look elsewhere.

Would you like me to create a comparison table showing exactly how gate valves stack up against ball and globe valves for specific industries?

Gate Valve vs. Other Valves: Quick Comparisons

In my experience dealing with industrial piping, picking the wrong valve type is the most common mistake I see. It usually comes down to not knowing the specific strengths of each design. While a gate valve is my go-to for on-off isolation, it isn’t a “do-it-all” solution.

Here is how the gate valve stacks up against the competition.

Gate Valve vs. Globe Valve Difference

This is the big one. The main gate valve vs globe valve difference lies in their purpose.

- Gate Valves: Designed strictly for isolation. The flow goes straight through with very little resistance.

- Globe Valves: Built for throttling (regulating) flow. The internal path forces the fluid to change direction, creating high flow resistance to control the volume.

Bottom line: If you need to turn flow on or off completely, stick with a gate valve. If you need to adjust the flow rate to 50%, grab a globe valve.

Gate vs. Ball Valve

A ball valve is a quarter-turn valve, meaning you can shut it off instantly. A gate valve is a multi-turn valve, requiring you to spin the handwheel many times to close it.

- Use [Motorized Ball Valves] or manual ball valves when you need quick, automated shut-off.

- Use Gate Valves when you want to avoid “water hammer” (pressure surges caused by stopping flow too fast) or need a full bore opening that matches the pipe size perfectly.

Gate vs. Butterfly Valve

[Wafer Butterfly Valves] are compact and lightweight, making them a popular choice in large-diameter pipes where space is limited and weight is a concern. However, the disc in a butterfly valve always sits in the flow stream, creating a slight obstruction.

In contrast, a gate valve retracts completely into the bonnet, offering a full bore opening with almost zero pressure drop. Choose the butterfly for space-saving; choose the gate for maximum flow efficiency.

Comparison at a Glance

| Feature | Gate Valve | Globe Valve | Ball Valve | Butterfly Valve |

|---|---|---|---|---|

| Primary Function | Isolation (On/Off) | Regulation (Throttling) | Isolation (Quick) | Isolation & Flow Control |

| Flow Resistance | Very Low | High | Low | Moderate |

| Operation Speed | Slow (Multi-turn) | Slow (Multi-turn) | Fast (Quarter-turn) | Fast (Quarter-turn) |

| Space Required | High (Vertical space) | High | Moderate | Low (Compact) |

When balancing cost and performance, I always recommend gate valves for main supply lines where flow efficiency is king. If you don’t need frequent cycling, they offer the best value.

Would you like me to detail the specific industrial applications where these differences matter most?

Industrial Gate Valve Applications and Uses

In my industry experience, gate valve applications are incredibly diverse. Because these valves are designed strictly for on/off service rather than throttling, they are the go-to standard for isolation across almost every major sector in the United States. We rely on them anywhere we need a straight-line flow with minimal restriction.

Here is a breakdown of where we use specific types of gate valves to get the job done:

Water and Wastewater Treatment

In municipal water systems, we almost exclusively use the resilient seated gate valve. Unlike older metal-seated versions, the resilient wedge has a rubber coating that creates a bubble-tight seal. This is crucial for wastewater lines where small debris might otherwise prevent a complete closure.

- Best fit: Resilient seated gate valves (AWWA standards).

- Role: Main isolation in distribution networks and pump stations.

Oil and Gas Sector

The energy sector requires valves that can handle high pressure and dirty crude. Here, the slab gate valve and through conduit gate valve are kings. They feature a full-bore design that matches the pipe’s internal diameter exactly, allowing for the passage of “pigs” (cleaning devices) through the pipeline without obstruction.

- Best fit: Slab/expanding gate valves.

- Role: Wellheads, transmission pipelines, and refineries.

Power Generation and Steam Systems

When dealing with high-pressure steam, thermal expansion is a real threat. A solid wedge might expand and get stuck in the seat (thermal binding). This is where flexible wedge gate valve advantages come into play; the slight flexibility allows the disc to adjust to temperature changes without locking up.

- Best fit: Flexible wedge gate valves (often pressure seal bonnets).

- Role: Steam isolation and feedwater systems.

Mining, Pulp, and Paper

If you are moving thick sludge, pulp stock, or slurry, a standard wedge will clog instantly. We use a knife gate valve for these aggressive media. As the name implies, the gate is a sharp blade that cuts through solids to close the line.

- Best fit: Knife gate valves (Stainless steel).

- Role: Handling slurries, powder, and viscous fluids.

Chemical and General Manufacturing

From HVAC lines to fire protection systems (OS&Y type), these valves are everywhere. In chemical processing, the focus shifts to materials. We use high-grade stainless steel or alloy bodies to resist corrosion while maintaining the standard gate valve working principle of low pressure drop.

Would you like me to create a maintenance checklist to help extend the lifespan of these specific gate valve types?

Selection and Installation Best Practices

When I’m helping clients spec out a project, I always tell them that picking the right valve is just as important as the pipe itself. You can’t just grab any gate valve off the shelf and expect it to hold up. You need to match the specific gate valve parts and materials to your actual operating conditions. If you get this wrong, you’re looking at leaks, failures, and expensive downtime.

Factors to Consider Before Buying

Before you install anything, you need to evaluate a few critical factors to ensure the valve handles the job. Here is what I look for:

- Media Type: What is flowing through the line? Clean water, slurry, or corrosive chemicals? A knife gate valve is essential for slurries, while standard wedges work for clean liquids.

- Pressure and Temperature: Check the pressure/temperature rating. For high-pressure steam or oil applications, you need valves that meet strict ANSI class ratings.

- Space Constraints: If you are tight on vertical space, go with a non-rising stem gate valve. If you have room and need to see if the valve is open from a distance, the rising stem gate valve or an OS&Y gate valve (Outside Screw and Yoke) is the better call.

- Actuation Needs: Do you need a manual handwheel, or will this be automated? Large valves often require gear operators or electric actuators.

Choosing the Right Material

In the US market, material selection usually comes down to the fluid and the environment. Here is a quick breakdown of the common choices:

- Cast Iron / Ductile Iron: The go-to for water, wastewater, and HVAC. It’s cost-effective but has lower pressure limits.

- Carbon Steel: The standard for the oil & gas industry. It handles high pressure and high temperatures well.

- Stainless Steel: Necessary for corrosive environments, chemical processing, or food-grade applications.

- Bronze: Common in marine environments and low-pressure plumbing due to corrosion resistance.

Standards Compliance (API, ANSI, DIN, ISO)

Never cut corners on compliance. In the global valve industry, we strictly adhere to major international standards.

- API (American Petroleum Institute): For the oil & gas sector, API 600 or API 602 compliance ensures the valve wall thickness and stem diameter can handle the stress.

- DIN & ISO: For European and general industrial projects, we ensure our valves meet DIN 3202 and ISO dimensions for seamless interchangeability.

Whether you are in Texas or Dubai, ensuring your valves meet these certifications is the only way to guarantee safety and longevity.

Maintenance Tips for Longevity

Once the valve is installed, keeping it running is straightforward if you follow the rules. The biggest mistake I see? People trying to use a gate valve for throttling.

- Avoid Partial Opening: I cannot stress this enough—gate valves are for full open or full closed service only. Throttling causes vibration that destroys the seats and wedge.

- Regular Lubrication: Grease the stem threads regularly, especially on rising stem models exposed to the elements.

- Periodic Cycling: If a valve sits in one position for months, it can seize up. Operate it occasionally to keep the gate from getting stuck.

Conclusion: Ensuring Reliability in Industrial Isolation

Gate valves remain the primary standard for full-bore isolation across process industries. However, their operational success depends entirely on matching the specific valve architecture—whether wedge, knife, or slab—to your unique fluid dynamics and pressure conditions.

Need Specialized Valve Solutions?

Navigating standards like API and ASME to find the right isolation strategy can be complex. At Delco Valve, we specialize in high-performance industrial valve solutions tailored to rigorous project specifications.

For technical consultation or to discuss your specific isolation requirements, contact the Delco Valve engineering team today. Let us help you ensure long-term containment integrity and operational safety.

Contact Us

In This Article

Solenoid Valve Guide: Working Principle, Types & Applications

Dec 30, 2025

Gate Valve Guide: Working Principles, Types & Uses (2026)

Dec 30, 2025

Wafer Butterfly Valve: Working Principle, Types & Advantages Guide

Dec 29, 2025

Motorized Ball Valve: The Complete Guide to Types, Wiring, and Selection

Dec 29, 2025