Home /

Home / Pneumatic Actuator Valves: The Ultimate Guide to Selection and Use (2026)

Pneumatic Actuator Valves: The Ultimate Guide to Selection and Use (2026)

Jan 14, 2026

Actuated Valve Guide: Working Principle, Types & Selection

Dec 31, 2025

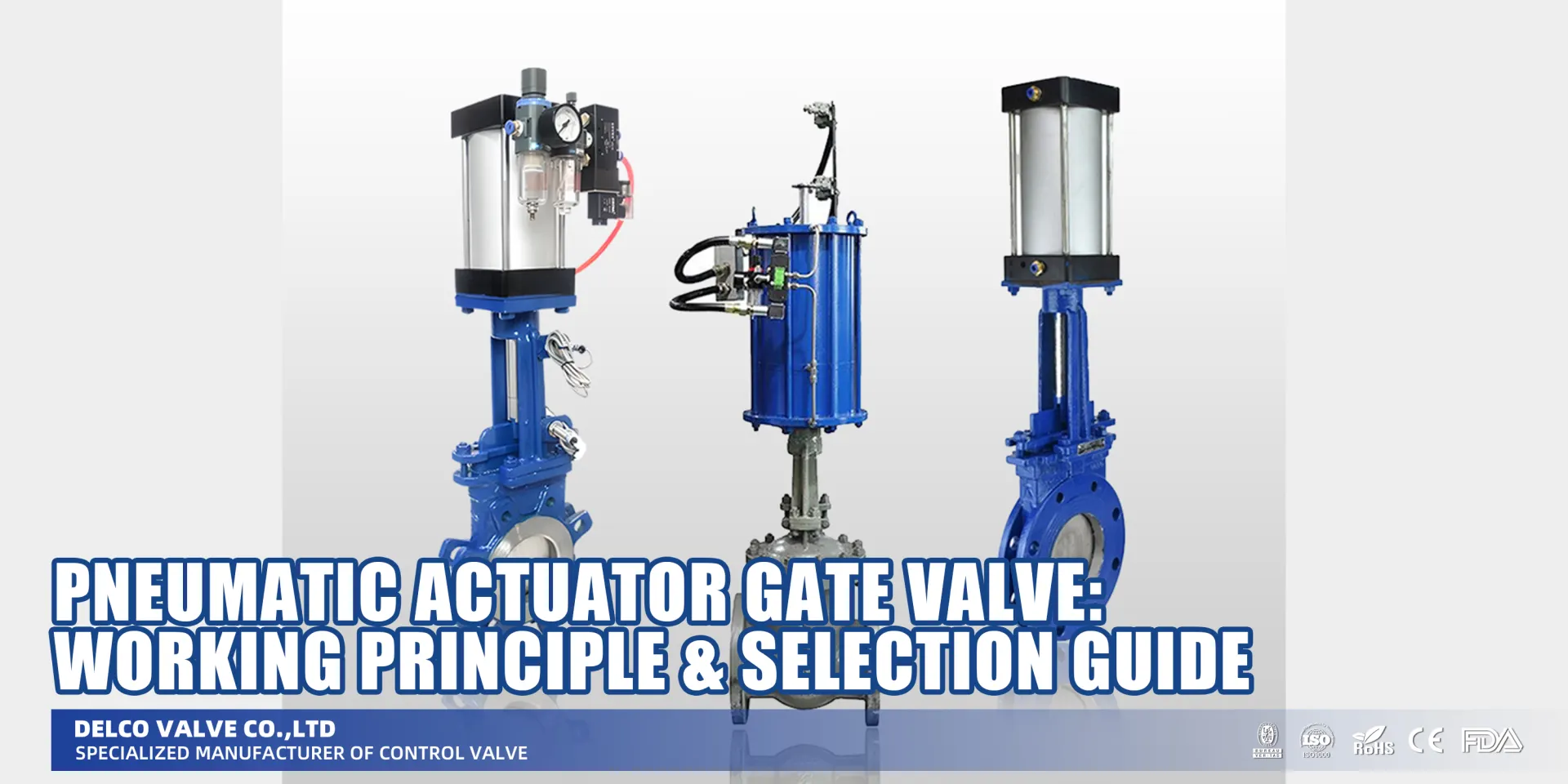

Pneumatic Actuator Gate Valve: Working Principle & Selection Guide

Dec 31, 2025

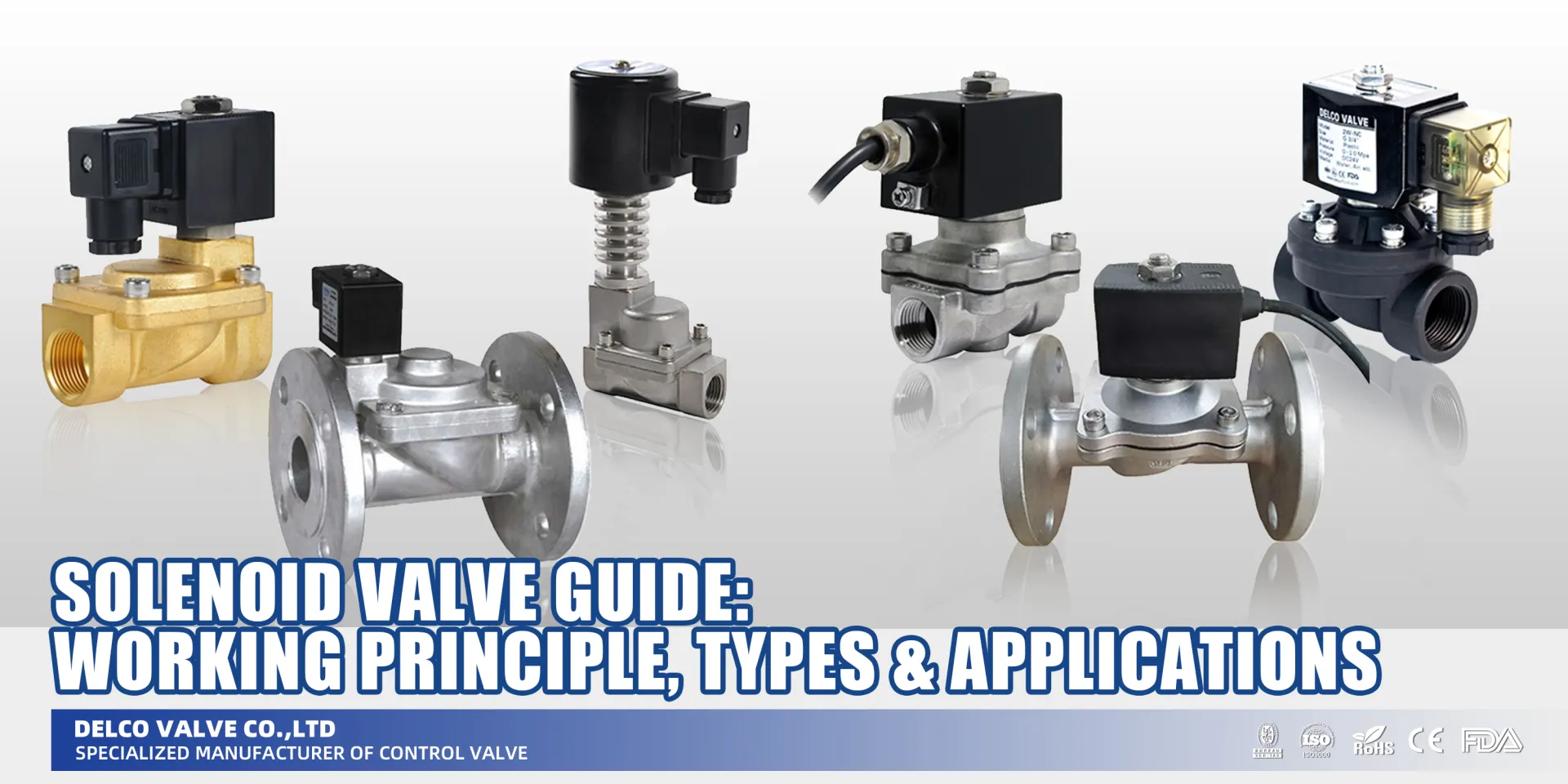

Solenoid Valve Guide: Working Principle, Types & Applications

Dec 30, 2025

Relying on outdated valve specs? You are likely overpaying for energy and compromising safety.

The rules have shifted for 2026. With the rise of smart pneumatics and IoT monitoring, selecting the right actuator is no longer just about torque—it's about future-proofing your facility.Whether you are sizing a rack and pinion unit for water lines or a critical fail-safe system for hazardous zones, precision is non-negotiable.

Drawing from Delco's 20+ years of field experience, this guide cuts through the noise. We cover everything from real-world sizing calculations to the latest ISO 5211 standards.

Let’s dive in.

Core Principles: How Pneumatic Actuator Valves Operate

At Delco Valves, we engineer our pneumatic actuated valves to serve as the muscle behind industrial automation. The fundamental operation is straightforward yet powerful: we convert the potential energy of compressed air into mechanical motion—either rotary (quarter-turn) or linear. This allows for rapid response times and high-force output, making air operated valves the preferred choice for process industries requiring speed and reliability.

Double-Acting vs. Spring Return Configurations

Choosing the right configuration is the first step in system design. We offer two primary actuation methods based on your control needs:

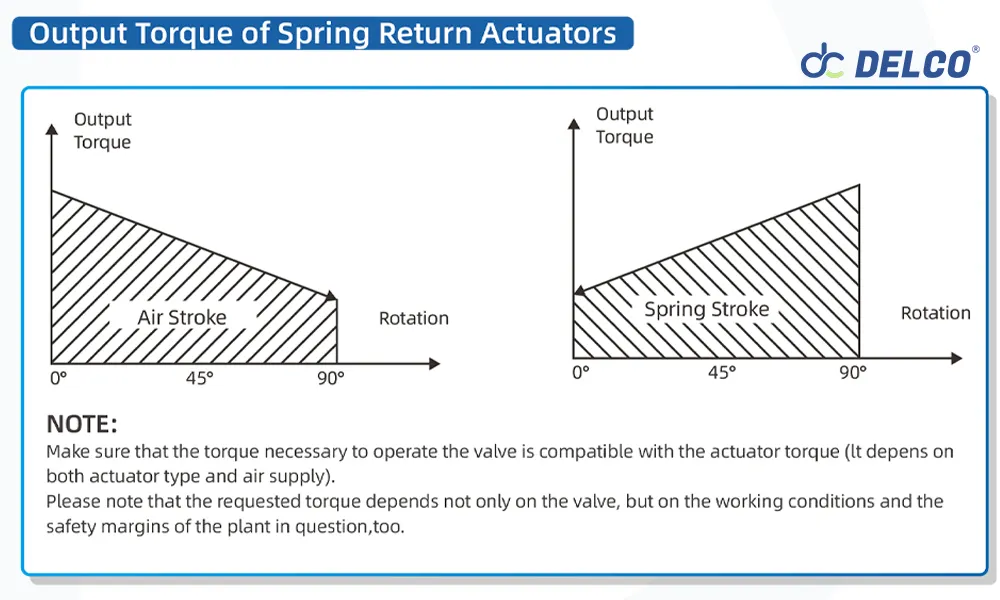

- Double Acting Pneumatic Actuator: This setup requires air pressure to both open and close the valve. It offers control over the speed of operation in both directions and typically provides a more compact footprint for the same torque output.

- Spring Return Actuator (Single-Acting): This design uses air pressure to move the valve in one direction (compressing internal springs) and relies on the mechanical force of the springs to return the valve to its original position when air is vented.

Fail-Safe Mechanisms for Emergency Shutdown

Safety is not optional in sectors like Oil & Gas or Chemical Processing. Our spring return actuators are the backbone of fail-safe valve actuation. If the compressed air supply fails or electrical power to the pilot valve is lost, the spring automatically forces the valve into a pre-determined safe state—either Normally Closed (NC) to stop flow or Normally Open (NO) to vent pressure. This mechanical redundancy is critical for preventing catastrophic system failures.

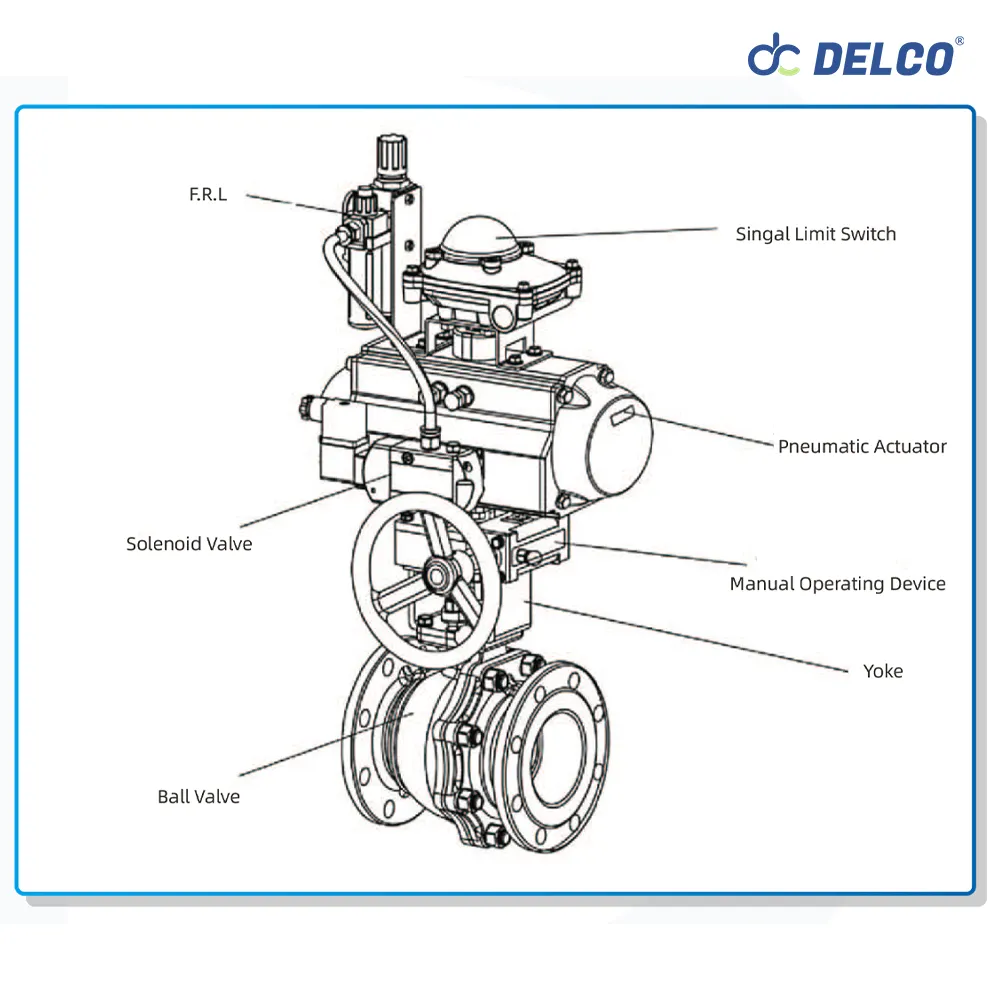

Critical Components Breakdown

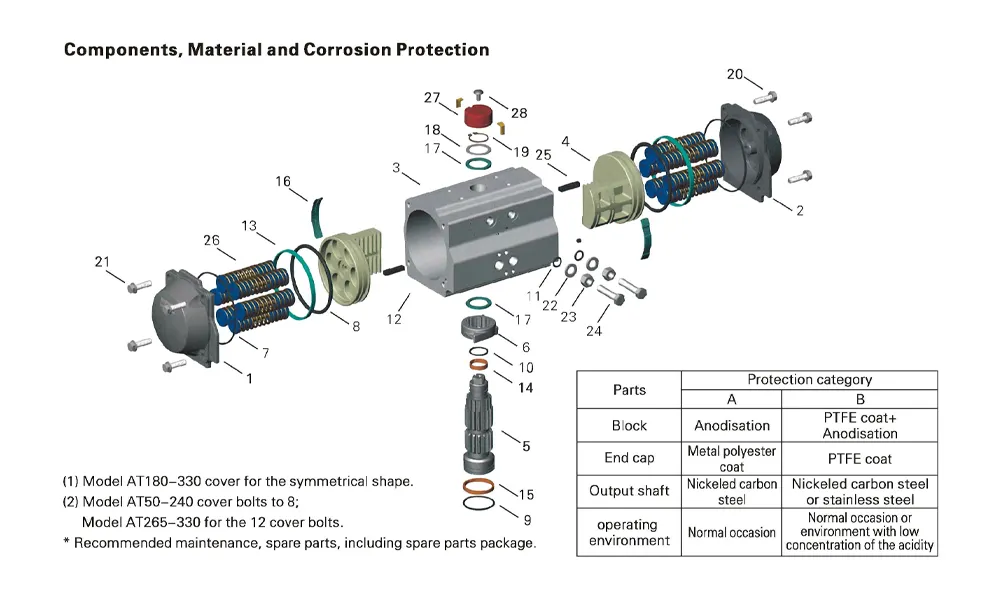

A pneumatic actuator valve is an assembly of precision-engineered parts working in unison. Our manufacturing process ensures seamless integration via ISO 5211 mounting standards:

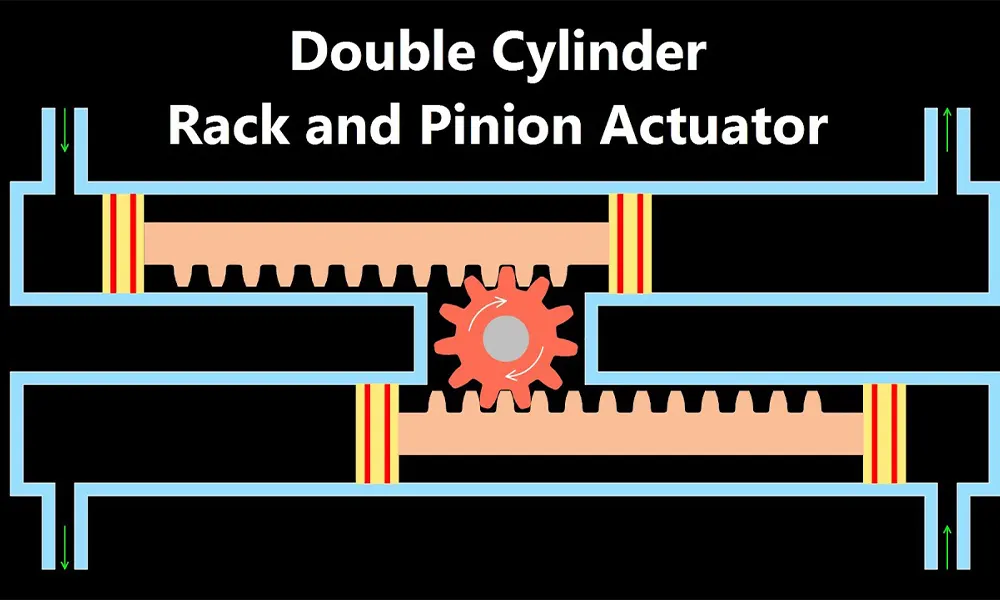

- Rack and Pinion Actuator (AW Series): Utilizing a dual-piston design, these provide constant torque output across the entire stroke, making them ideal for high-cycle ball and butterfly valves.

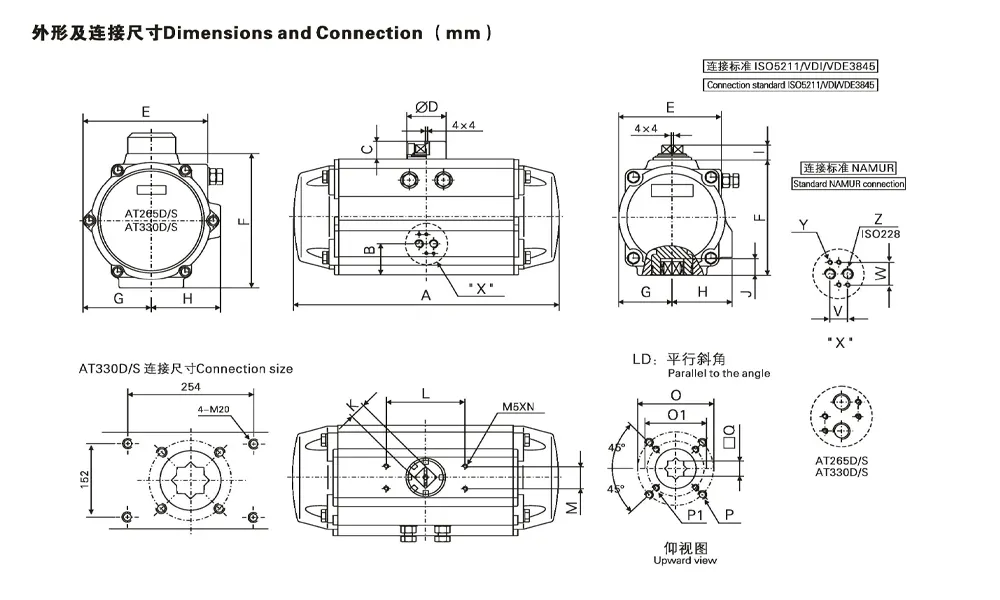

- Scotch Yoke Pneumatic Actuator (AT Series): Engineered for heavy-duty applications, the scotch yoke mechanism delivers high torque at the beginning and end of the stroke, exactly where large valves need it most to unseat or seal.

- NAMUR Solenoid Valve: This pilot valve acts as the 'brain' of the assembly, directing airflow into the actuator chambers based on electronic signals. Understanding how these distinct components interact is vital; if you are unsure about the specific mechanics of the pilot, check out our comprehensive [Solenoid Valve Guide: Working Principle, Types & Applications]to choose the right control voltage and configuration.

- Positioners: For applications requiring flow modulation, we integrate smart positioners that adjust the valve stem position based on a 4-20mA signal, transforming a standard on/off valve into a precise control instrument.

Types of Pneumatic Actuators and Their Ideal Valve Pairings

Selecting the correct actuation method is the difference between a smooth operation and a maintenance nightmare. We categorize our pneumatic solutions based on motion profile and torque delivery, ensuring every valve type—from standard water lines to abrasive slurries—gets the precise power it needs.

Rotary Actuators: The Quarter-Turn Standard

For the vast majority of industrial applications involving pneumatic ball valves or butterfly valves, rotary motion is the standard. These actuators turn the valve stem 90 degrees to open or close the flow.

- Rack-and-Pinion (AW Series): This is the industry workhorse. We design our AW series for compact spaces and high-cycle applications. The dual-piston mechanism provides constant torque output, making it the ideal match for on/off quarter-turn valves in water treatment and general processing.

- Scotch Yoke (AT Series): When you are dealing with larger pipeline diameters or high-pressure drops, you need more muscle. The Scotch yoke pneumatic actuator delivers a non-linear torque curve, providing maximum force at the beginning (break-open) and end (closing) of the stroke. This is critical for seating large pneumatic butterfly valves securely.

Left: AW Rack-and-Pinion Pneumatic Actuator; Right: AT Scotch Yoke Pneumatic Actuator

Linear Actuators for Direct Motion

Not all valves spin. For applications requiring precise throttling or handling slurries, linear motion is required. Our linear actuators connect directly to the stem to push and pull the closure element.

- Gate and Globe Valves: These require multi-turn or long-stroke linear actuation, often used in steam and high-pressure regulation.

- Knife Gate Valves: Essential for wastewater and paper pulp, these pair with heavy-duty linear cylinders to cut through solids without clogging.

Specialty Configurations for Extreme Environments

Standard setups don’t work everywhere. We customize solutions for specific industry challenges:

- Sanitary Tri-Clamp: For food and pharma, we pair polished stainless steel actuators with hygienic valves to meet FDA standards.

- Fluorine-Lined Valves: In chemical processing, standard metals fail. We use fluorine-lined bodies paired with corrosion-resistant actuators to handle aggressive acids.

- High-Pressure Solutions: For the oil and gas sector, our actuators are built to withstand extreme internal pressures and harsh offshore conditions.

Quick Selection Matrix:

| Actuator Type | Motion | Ideal Valve Pairing | Best Application |

|---|---|---|---|

| Rack-and-Pinion | Rotary (90°) | Ball, Butterfly, Plug | General automation, high-cycle |

| Scotch Yoke | Rotary (90°) | Large Ball, High-Performance Butterfly | Heavy-duty, high-torque needs |

| Linear Cylinder | Linear | Gate, Globe, Knife Gate | Throttling, slurry handling |

Complete Selection Guide: Matching the Right Actuator to Your Application

Selecting the correct pneumatic actuator valve is the difference between a smooth operation and a costly shutdown. At Delco, we don’t rely on guesswork; we rely on engineering precision to match the actuator’s output to the valve’s specific demands. Whether you are retrofitting an existing line or building a new facility, getting the sizing and specifications right the first time is critical for safety and efficiency.

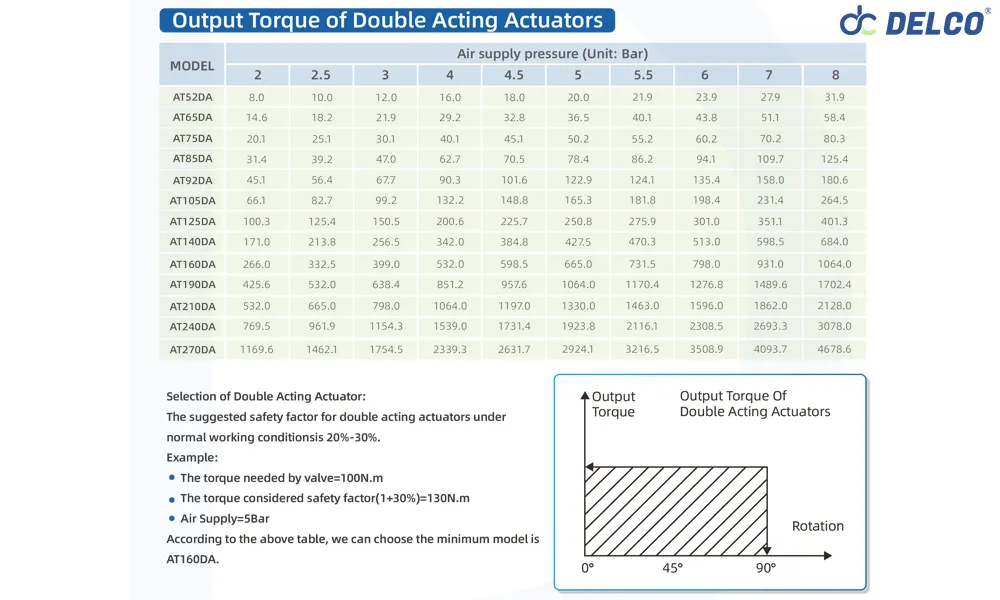

Critical Factors: Torque and Air Supply

The most vital metric in valve automation is torque. You must determine the “break-torque” required to unseat the valve ball or disc. This requirement changes based on the media pressure and viscosity.

- Torque/Output Requirements: The actuator must deliver enough force to open and close the valve under maximum differential pressure.

- Air Supply Pressure: Standard industrial air supply usually fluctuates. We size our AT Scotch Yoke and AW Rack-and-Pinion actuators to operate reliably within your specific air pressure range, ensuring consistent performance even if plant air drops slightly.

- Cycle Frequency: High-cycle applications require robust internal components to prevent wear.

Sizing Methodology: How We Calculate for Safety

The "Monday Morning" Factor: Why Standard Sizing Fails

If there is one piece of advice I give to every engineer, it is this: Do not trust the datasheet blindly.

Here is a scenario we see too often at Delco: A client sizes an actuator based on a brand-new valve’s torque chart. It works perfectly during the test run. But six months later, on a Monday morning after the plant has been idle for the weekend, the valve fails to open.

Why? Because of "Stiction" (Static Friction).

When a valve sits closed under pressure, the soft seats deform slightly against the ball or disc. The torque required to "break" this seal (Breakaway Torque) can spike by 40% or more compared to the running torque.

Our Recommendation:

When we size actuators for critical lines, we treat the standard 30% safety factor as a minimum requirement, not a suggestion. If your application involves infrequent cycling or viscous media, we recommend upsizing the actuator model. Paying an extra $50 for a larger actuator today is infinitely cheaper than a $5,000 shutdown caused by a stuck valve next Monday.

Material Selection: Matching the Alloy to Your Media

We don't believe in "one size fits all." When you send us your specs, we look immediately at your media compatibility.

- For General Water/Air: We typically recommend Ductile Iron. It offers the best balance of strength and cost-efficiency for non-aggressive lines.

- For Corrosive Acids: We will steer you directly towards our Fluorine-lined or Stainless Steel 316 options. We have seen too many carbon steel valves eaten away by unnoticed chemical traces, so we prioritize longevity over the lowest initial bid.

Essential Standards and Compliance

Compatibility and safety are non-negotiable. Our manufacturing process adheres to global standards to ensure seamless integration and legal compliance across borders.

- Mounting Interfaces: We utilize ISO 5211 standard mounting pads, making our actuators universally compatible with most valve stems.

- Solenoid Interfaces: NAMUR standards ensure easy integration of pilot valves and accessories.

- Safety Certifications: For hazardous industries like Oil & Gas, we provide ATEX certified explosion-proof options and SIL rated reliability.

- Hygiene Standards: Our sanitary valves meet FDA requirements for food and pharmaceutical safety.

2026 Advancements: Smart and IIoT-Enabled Pneumatic Actuator Valves

The industrial landscape has shifted. We aren’t just bolting mechanical devices onto pipes anymore; we are integrating intelligent nodes into a global network. At Delco Valves, our move toward Industry 4.0 means pneumatic actuator valves are now critical data points in your facility’s nervous system. The 2026 standard is defined by connectivity, where compressed air meets computation.

Integrating Smart Positioners and Protocols

Modern automation demands more than simple open/close functionality. We are seeing a massive uptake in smart pneumatic actuators equipped with advanced positioners supporting HART, Foundation Fieldbus, and Profibus protocols. These aren’t just responding to 4-20mA signals; they are communicating bi-directionally.

- Precision Control: Digital positioners allow for micro-adjustments in flow, vital for our pneumatic globe control valves used in chemical dosing.

- Seamless Integration: Plug-and-play compatibility with existing DCS and PLC systems reduces installation time.

Real-Time Diagnostics and Predictive Maintenance

The era of “run-to-failure” is over. With IoT valve monitoring, our actuators provide real-time feedback on valve health. Sensors embedded in the assembly track performance metrics, enabling predictive maintenance pneumatics. Instead of scheduling maintenance based on a calendar, you schedule it based on actual wear data.

Key Diagnostic Metrics:

- Valve Signature Analysis: Detects increased friction or sticking before the valve seizes.

- Air Supply Monitoring: Identifies pressure drops or leaks in the supply line immediately.

- Cycle Counting: Tracks total strokes to predict seal life expectancy.

Energy Efficiency and IIoT Readiness

Data-driven insights directly translate to cost savings. By monitoring air consumption through smart modules, operators can identify inefficiencies in the pneumatic loop. Our manufacturing process utilizes AI-powered inspection to ensure every unit is built to these exacting standards. Whether you are running a digital twin simulation or managing a remote offshore rig, IIoT-ready solutions ensure your valves deliver maximum uptime with minimal energy waste.

Industry-Specific Applications and Case Examples

After two decades of manufacturing and supplying pneumatic actuator valves globally, we know that a valve’s success depends entirely on how well it handles its specific environment. We don’t just sell off-the-shelf units; we engineer solutions tailored to the unique demands of critical industries. From the freezing North Sea platforms to sterile cleanrooms in Germany, here is how our air operated valves deliver value across different sectors.

Oil & Gas: Safety in Hazardous Zones

In the oil and gas sector, failure isn’t an option. We design our pneumatic actuated valves to withstand extreme pressures and volatile environments.

- Explosion-Proof Compliance: Our actuators feature ATEX and SIL certifications, ensuring safe operation in potentially explosive atmospheres.

- Rugged Protection: We utilize IP67 and IP68 protection classes to prevent ingress from seawater and dust in offshore and onshore rigs.

- High-Pressure Handling: Our heavy-duty Scotch Yoke pneumatic actuators provide the necessary torque to shut off large pipeline valves instantly during emergency shutdowns.

Chemical Processing: Combating Corrosion

Handling aggressive acids and alkalis requires materials that won’t degrade. We specialize in corrosion-resistant solutions that extend service life and prevent leaks.

- Lined Valve Technology: We offer fluorine-lined and PTFE-lined pneumatic ball and butterfly valves. These provide a robust barrier against corrosive media that would destroy standard metals.

- Specialized Materials: Beyond standard stainless steel, we manufacture valves using specialized plastics and alloys designed specifically for harsh chemical compatibility.

- Precise Modulation: For chemical dosing, our pneumatic globe control valves with smart positioners ensure exact concentration levels are maintained.

Pharmaceutical & Food: Hygiene First

For our partners in the food, beverage, and pharma industries, contamination control is the priority. Our sanitary pneumatic valves are built to meet strict health standards.

- FDA Compliance: All wetted parts and elastomers are fully FDA-compliant, ensuring product safety.

- Clean-in-Place (CIP) Ready: Our designs feature smooth, crevice-free surfaces (like our sanitary butterfly and diaphragm valves) that support rigorous CIP and SIP (Sterilization-in-Place) protocols.

- Stainless Steel Construction: We use high-grade stainless steel that resists bacterial growth and withstands frequent washdowns.

Water Treatment & Power Generation: Durability at Scale

Municipal water systems and power plants demand reliability over long cycles. Our valves are engineered for high-flow efficiency and temperature resilience.

- Zero-Leakage Assurance: Our pneumatic butterfly valves (wafer and lug types) utilize durable EPDM or NBR seats to ensure a tight seal, preventing water loss.

- High-Temperature Performance: For power generation steam lines, we supply metal-seated valves capable of handling extreme heat without seizing.

- Cost-Effective Automation: We provide robust ductile iron options that offer high performance at a manageable cost for large-scale infrastructure projects.

Installation, Maintenance, and Troubleshooting Best Practices

Getting the most out of your pneumatic actuator valve starts long before you flip the switch. At Delco Valves, we have seen that nearly 80% of field failures stem from improper installation or neglected air supply quality. Whether you are deploying a compact rack and pinion actuator or a heavy-duty scotch yoke unit, following a strict installation guide and maintenance schedule is non-negotiable for process safety and longevity.

Step-by-Step Mounting and Alignment (ISO 5211)

Correct alignment is the foundation of a reliable air operated valve. While the ISO 5211 standard simplifies the interface, the actual assembly requires precision. For a detailed, visual walkthrough on assembling quarter-turn units, I highly recommend following our step-by-step [Pneumatic Ball Valve Installation Guide for Beginners]. It covers specific torque settings and alignment tricks that prevent premature stem wear.

- Clean the Interface: Ensure the valve stem and actuator drive are free of debris.

- Check the Position: Both the valve and the actuator must be in the same position (usually closed) before assembly.

- Align the Stem: Insert the valve stem into the actuator drive socket. It should slide in without force.

- Tighten Evenly: Secure the mounting bolts in a cross/star pattern to prevent uneven stress on the stem seal.

- Test Run: Manually cycle the valve (if equipped with a manual override) to check for binding before connecting the air supply.

Routine Checks: Air Quality and Seal Integrity

The lifespan of a pneumatic valve is directly tied to the quality of the compressed air driving it. Contaminated air destroys internal seals and cylinders.

- Air Supply Quality: Ensure your air is clean, dry, and regulated. Install a filter-regulator-lubricator (FRL) unit upstream. Moisture causes corrosion inside carbon steel or ductile iron bodies, while particulates score the pistons.

- Seal Inspection: periodically check for audible air leaks around the output shaft and end caps. If you are using our AT series or AW series actuators in harsh environments, inspect the external seals for chemical degradation.

- Lubrication: While many of our modern actuators are factory-lubricated for life, high-cycle applications may require periodic regreasing of the rack or yoke mechanism to maintain smooth torque transmission.

Case Study: The Cost of Ignoring Air Quality

Last year, we assisted a textile plant with a retrofit project. To save budget, they decided to rely on their central compressor’s drying system and skipped installing local FRL (Filter-Regulator-Lubricator) units near the valves.

The Result: Within three months, they faced multiple actuator failures. When our team opened the units for inspection, the interiors looked like they had been dipped in mud. Moisture condensation had traveled through the lines, washing away the factory grease and rusting the internal springs of the Single-Acting units.

The Lesson: A pneumatic actuator is only as reliable as the air driving it. At Delco, we consider the installation of an FRL unit within 5 meters of the valve mandatory. Clean, dry air isn't a luxury; it's the lifeblood of your automation.

Common Issues and How We Solve Them

In our 20+ years of supporting plant managers, we’ve found that 90% of "valve failures" aren't actually valve failures at all—they are system issues.

Before you order a replacement, I recommend checking the basics. We created this quick troubleshooting matrix based on the most frequent support calls our engineering team receives:

| Issue | Potential Cause | Recommended Action |

|---|---|---|

| Valve Fails to Move | Low air supply pressure or jammed valve | Check air pressure against the nameplate; inspect valve for debris blockage. |

| Slow Operation | Clogged exhaust muffler or restricted air line | Clean or replace the silencer; check air lines for kinks. |

| External Air Leakage | Worn piston seals or O-rings | Replace the seal kit (ensure material compatibility like Viton or NBR). |

| Inaccurate Positioning | Smart positioner calibration drift | Perform auto-calibration on the positioner; check feedback linkage. |

Pro Maintenance Tip: The "Quiet Shift" Walkthrough

You don't always need advanced IoT sensors to catch problems early. One of the most effective maintenance routines is also the simplest.

I encourage plant managers to walk their pneumatic lines during a shift change or a lunch break when the factory floor is relatively quiet.

Listen for the hiss.

A clearly audible hiss from a valve positioner or actuator seal might seem minor, but at 100 PSI (7 bar), that single leak can cost you over $600 per year in wasted electricity for your compressor. If you can hear it, tag it immediately. Most catastrophic actuator failures start as a simple $5 O-ring leak that was ignored for too long.

Extending Service Life with Proactive Strategies

Reactive maintenance costs time and money. To keep your pneumatic actuated valve running efficiently through 2026 and beyond, adopt a predictive approach. Monitor cycle times; a valve that starts closing slower than usual is often signaling seal wear or air supply issues. For critical fail-safe applications, test the spring-return function regularly to ensure the springs haven’t fatigued. By sticking to these protocols, you protect your investment and ensure your facility operates without unplanned downtime.

Pneumatic vs. Alternatives: A 2026 Comparison

In the world of industrial automation, choosing between pneumatic, electric, and hydraulic actuation isn’t just about preference—it’s about matching the physics to the process. While we focus here on pneumatic advantages, many engineers struggle with the electric vs. pneumatic decision. To dig deeper into that specific tradeoff, you can read our detailed breakdown on the [Difference Between Motorized Valves and Solenoid Valves]. At Delco, we have spent over 20 years engineering pneumatic actuator valves because they offer a specific balance of speed, safety, and reliability that other methods often struggle to match.

Why Pneumatic Still Wins on Speed (The "Blink" Test)

In 2026, there is a lot of hype around "all-electric" automation. While electric valves are precise, they struggle to compete with pneumatics in one critical area: Reaction Speed.

Let’s talk physics. If you need to slam a 12-inch butterfly valve shut in under 0.5 seconds to prevent a hazardous chemical spill, an electric motor faces a massive challenge. It needs to overcome inertia and ramp up speed through a gearbox.

Pneumatic actuators operate on stored energy. When the solenoid trips, the compressed air (or spring) releases instantly. It is the difference between waiting for a car to accelerate versus releasing a tensioned bowstring. For Emergency Shutdown (ESD) loops, pneumatic actuation isn't just an "old-school option"—in my professional opinion, it remains the safest, most responsive choice available.

Comparison Matrix: Speed, Safety, and Cost

Here is a breakdown of how our pneumatic solutions stack up against the alternatives in modern facility designs.

| Feature | Pneumatic Actuators (Delco AW/AT Series) | Electric Actuators | Hydraulic Actuators |

|---|---|---|---|

| Power Source | Compressed Air (60-100 PSI) | Electricity (AC/DC) | Hydraulic Fluid |

| Response Speed | Fast (Instant linear/rotary motion) | Slow to Moderate | Moderate |

| Safety (HazLoc) | Excellent (Explosion-proof by design) | Requires complex NEMA/ATEX enclosures | Good, but fluid leaks are a risk |

| Fail-Safe | Simple (Spring Return mechanism) | Complex (Battery backup/capacitors) | Complex (Accumulators) |

| Maintenance | Low (Simple seals, easy to repair) | High (Gears, motors, electronics) | High (Fluid changes, leak checks) |

| Cost | Low to Medium | Medium to High | High |

| Torque/Force | Medium to High (Scotch Yoke) | Moderate | Very High |

When Pneumatic Excels: The Delco Perspective

We focus on manufacturing Rack and Pinion (AW Series) and Scotch Yoke (AT Series) actuators because they win in critical categories:

- Hazardous Environments: In Oil & Gas or Chemical processing, a spark can be catastrophic. A pneumatic actuated valve is inherently explosion-proof. There is no internal motor to spark, making it the safest choice for ATEX and SIL-rated zones without adding expensive shielding.

- High-Cycle Applications: If your process requires a valve to open and close hundreds of times a day, pneumatic is the answer. Our actuators are built for durability under high-frequency cycling, whereas electric motors can overheat or wear out gears rapidly under similar stress.

- Fail-Safe Reliability: Achieving a fail-safe state (Fail Open or Fail Close) is mechanical and passive with a spring return actuator. If air is lost, the spring forces the valve to its safe position immediately. Electric actuators require battery backups to achieve this, introducing another point of failure.

Despite the rise of all-electric systems, pneumatic control valves retain the majority market share in heavy industries.

- Process Industries: For water treatment, petrochemical, and food processing, the cost-to-torque ratio of pneumatic systems is unbeatable.

- Modulation: With modern smart positioners, we can achieve precise flow control comparable to electric servos but with the ruggedness of pneumatic hardware.

If you need a solution that is waterproof (IP67/IP68), handles extreme temperatures, and integrates seamlessly with ISO 5211 mounting standards, pneumatic actuation remains the industry standard for 2026 and beyond.

Frequently Asked Questions (FAQs)

What is the difference between single-acting and double-acting pneumatic actuators?

The main difference lies in how they control movement and handle safety.

- Double Acting Pneumatic Actuators: These require compressed air to both open and close the valve. They give you precise control in both directions and are generally more compact.

- Spring Return (Single Acting) Actuators: These use air to move in one direction (usually open) and mechanical springs to return to the original position when air is cut. This provides a fail-safe valve actuation mechanism, ensuring the valve defaults to a safe state (open or closed) during power or air loss.

How do I calculate the correct torque for actuator sizing?

Sizing isn’t a guessing game; it requires precise actuator sizing calculation. To get it right:

- Determine Valve Torque: Get the break-torque data from the valve manufacturer.

- Apply Safety Factor: We recommend adding a safety margin (typically 20% to 30%) to account for friction, media viscosity, and wear over time.

- Check Air Supply: Match the required torque against your available air supply pressure (usually 4-6 bar).

- Select Series: Use our AW Rack and Pinion for standard torque or AT Scotch Yoke for high-torque, heavy-duty needs.

Are pneumatic actuators suitable for hazardous environments (ATEX)?

Absolutely. In industries like Oil & Gas or Chemical processing, safety is non-negotiable. Our pneumatic actuated valves are designed to meet strict safety standards. We manufacture actuators with ATEX and SIL certifications, ensuring they are explosion-proof and safe for use in potentially volatile atmospheres. Always verify the specific zone requirements before installation.

What are the main benefits of upgrading to smart pneumatic actuators?

Moving to smart pneumatic actuators integrates your valves into the Industry 4.0 ecosystem. By adding smart positioners and feedback units, you gain:

- Real-time Monitoring: Track valve position and performance remotely.

- Predictive Maintenance: Identify wear on seals or drops in pressure before a failure occurs.

- Precise Control: Achieve high-precision modulation for temperature and concentration control, far beyond simple on/off functionality.

How often should pneumatic actuator valves undergo maintenance?

While our actuators are built for high-cycle durability, pneumatic valve maintenance is key to longevity.

- Routine Checks: Inspect air quality and NAMUR solenoid valve connections every 3-6 months.

- Seal Integrity: For high-cycle applications, check piston seals and ISO 5211 mounting alignment annually.

- Environment: Harsh environments (corrosive or dirty) require more frequent inspections to ensure the IP67/IP68 protection remains intact.

Conclusion: Future-Proofing Your Process

As we navigate the industrial landscape of 2026, the gap between a standard facility and a smart, efficient plant is widening. Selecting the right Pneumatic Actuator Valve is no longer just a hardware purchase—it is a strategic decision that impacts your safety, energy costs, and uptime.

Whether you are battling the "Monday Morning" stiction we discussed or integrating NAMUR-compliant smart positioners for a new production line, the margin for error is small.

Why Leave It to Chance?

At Delco Valves, we don't just ship boxes; we provide the engineering assurance behind them. From calculating the precise safety factor to recommending the right seal material for your corrosive media, our team ensures your actuation matches your application perfectly.

Ready to optimize your automation?

Don't let outdated specs hold your facility back.

👉 [Contact our Engineering Team] for a free sizing consultation.

👉 [Download the 2026 Actuator Catalog] to see our full range of AW and AT series specifications.

- PREV: Actuated Valve Guide: Working Principle, Types & Selection

- NEXT: Not NEXT

Contact Us

In This Article

Pneumatic Actuator Valves: The Ultimate Guide to Selection and Use (2026)

Jan 14, 2026

Actuated Valve Guide: Working Principle, Types & Selection

Dec 31, 2025

Pneumatic Actuator Gate Valve: Working Principle & Selection Guide

Dec 31, 2025

Solenoid Valve Guide: Working Principle, Types & Applications

Dec 30, 2025