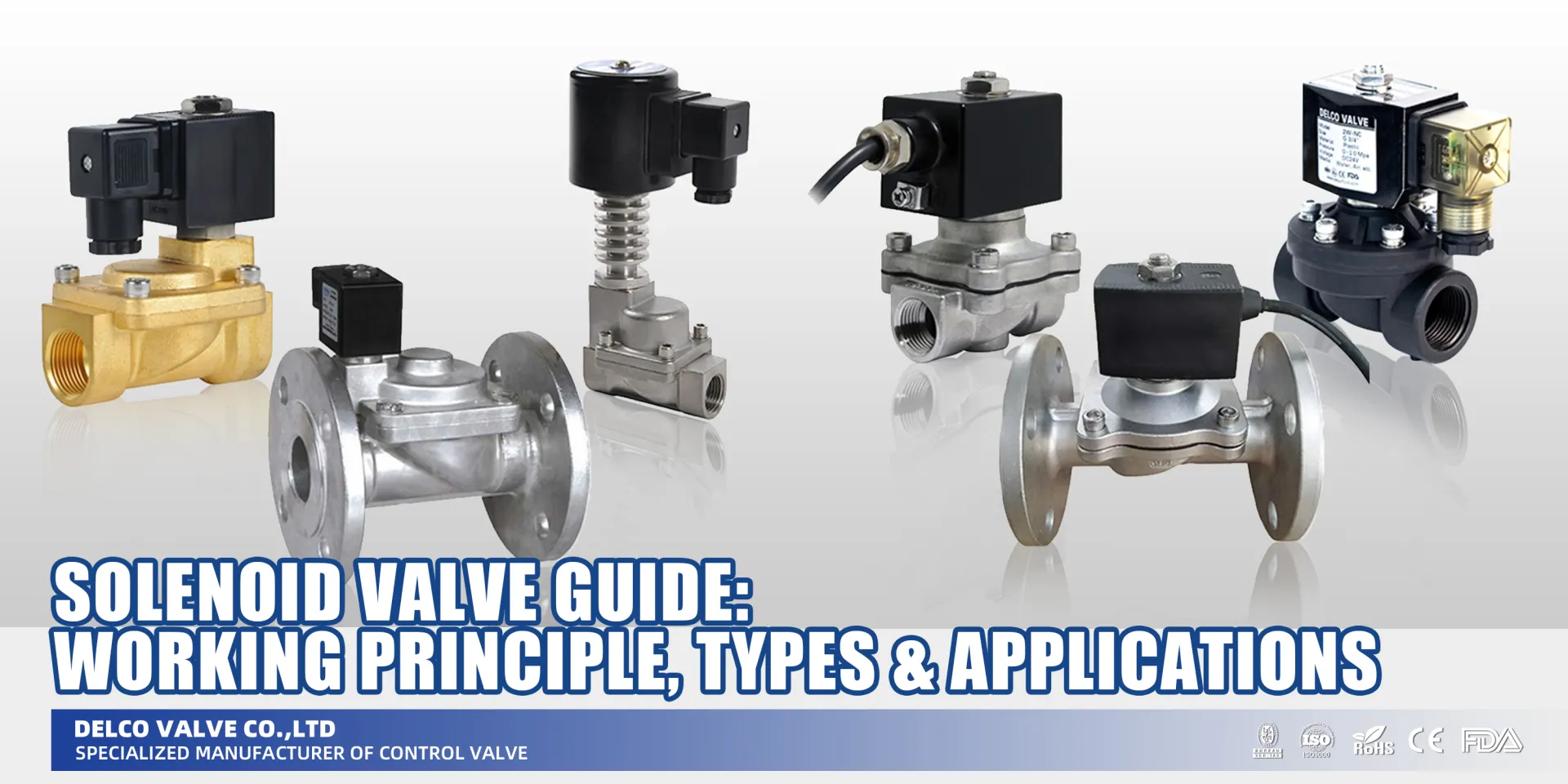

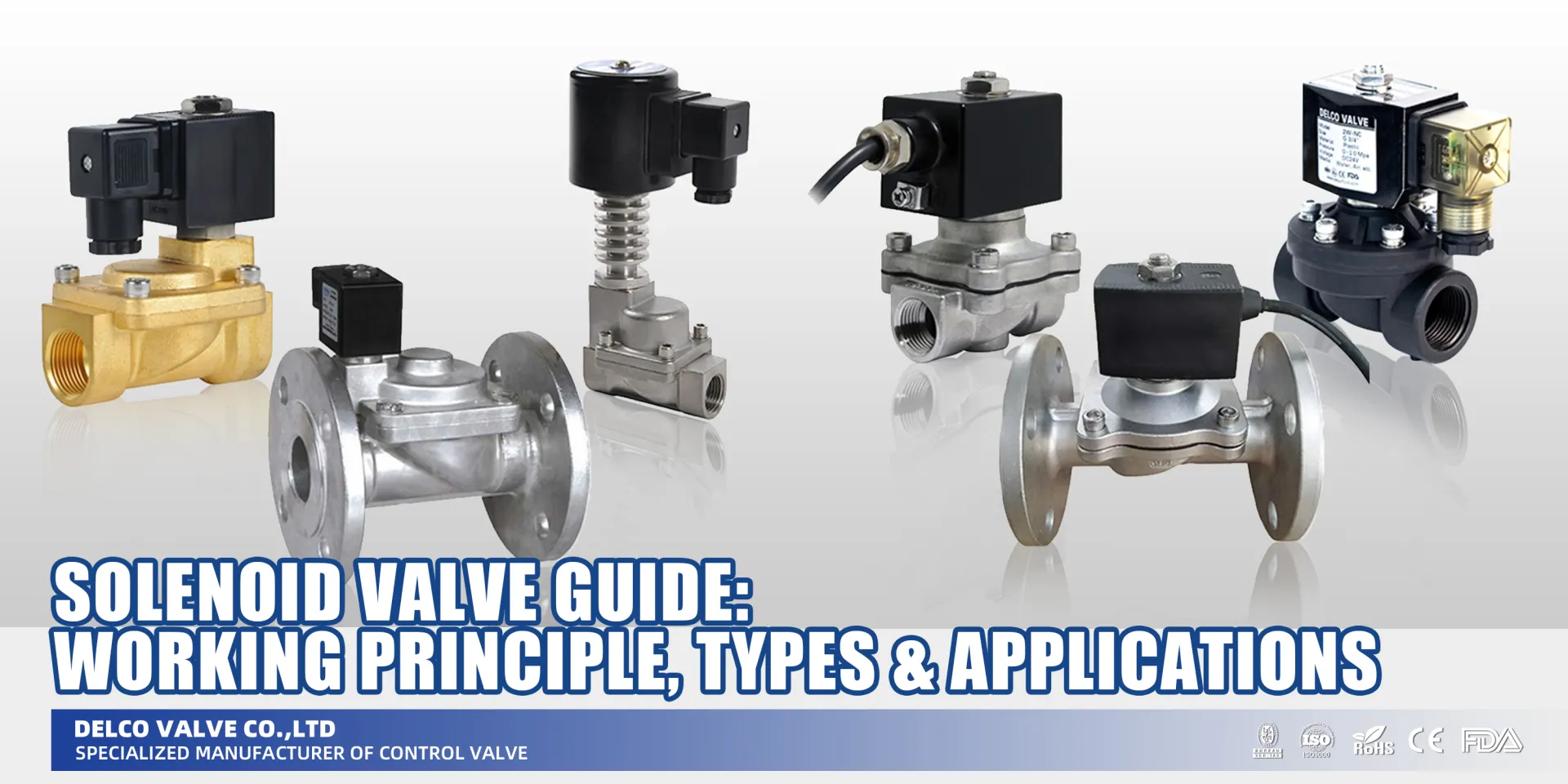

Solenoid Valve Guide: Working Principle, Types & Applications

Solenoid Valve Guide: Working Principle, Types & Applications

Dec 30, 2025

Gate Valve Guide: Working Principles, Types & Uses (2026)

Dec 30, 2025

Wafer Butterfly Valve: Working Principle, Types & Advantages Guide

Dec 29, 2025

Motorized Ball Valve: The Complete Guide to Types, Wiring, and Selection

Dec 29, 2025

Explore our solenoid valve introduction covering working principle types and applications. Master selection and maintenance in this complete guide.

What is a Solenoid Valve?

Have you ever wondered how an electrical signal actually stops high-pressure water, gas, or oil in an instant? That is the specific job of a Solenoid Valve.

Unlike manual valves that require physical effort (learn more in our complete guide on [What Is a Valve: Types, Parts, and Functions]), a solenoid valve acts as the critical handshake between your electronic control system and your physical piping. Instead of manually turning a handle, we use an electric current to trigger a magnetic field, opening or closing the valve automatically.

Core Components and Function

To understand how we get that precise control, you need to look inside the housing. The magic happens through a few robust internal parts working in unison:

- Electromagnetic Coil: This is the copper wire winding surrounding the core. When energized, it generates the magnetic field required for actuation.

- Plunger Armature: A ferromagnetic metal rod that moves up or down inside the tube. This is the only moving part in many designs.

- Spring: This critical component applies tension to return the plunger to its original position (either open or closed) once the power is cut.

- Orifice: The internal opening that the fluid flows through. The Orifice size directly dictates the flow rate and pressure drop.

- Seal/Disc: Attached to the plunger, this material presses against the orifice to stop leaks dead in their tracks.

Whether you are building a home irrigation system or an industrial hydraulic rig, understanding these basics is the first step to selecting the right hardware.

How Solenoid Valves Work: The Mechanics Inside

When we strip away the complex housing, the solenoid valve working principle is actually straightforward physics. It isn’t magic; it is electromagnetism in action. At the heart of the operation is the conversion of electrical energy into mechanical force.

Here is the breakdown of what happens inside the valve body:

- The Setup: We have a wire coil wrapped around a metallic core (the armature).

- The Power: When we apply AC or DC voltage to the electromagnetic coil, it generates a concentrated magnetic field.

- The Action: This magnetic field turns the coil into an electromagnet, creating a strong attractive force.

This force is what interacts with the plunger armature. Depending on the valve design, the magnetic field either pulls the plunger up or pushes it down to overcome the resistance of the internal spring. This movement is what opens or closes the orifice, allowing media to flow or stopping it dead in its tracks.

The Cycle: From De-Energized to Energized

Understanding the transition between states is key to controlling your system. Let’s look at how the plunger moves during a standard operation cycle:

- De-Energized State: Without power, the magnetic field is gone. The spring force dominates here, pushing the plunger into its resting position. In most safety setups, this seals the valve tight against the seat.

- Energized State: Once we hit the switch and power the coil, the magnetic force overcomes the spring. The plunger lifts (or shifts), opening the flow path.

- Return to Rest: As soon as the power cuts, the magnetic field collapses instantly. The spring snaps the plunger back to its original position, resetting the valve.

Understanding NC vs. NO Behavior

When selecting a valve for your US-based facility, you will constantly run into the terms Normally Closed (NC) and Normally Open (NO). This refers to the valve’s state when there is no power applied. Choosing the wrong one can lead to safety hazards or wasted energy.

Here is the cheat sheet on how they differ:

| Feature | Normally Closed (NC) | Normally Open (NO) |

|---|---|---|

| Default State | The valve is closed when de-energized. | The valve is open when de-energized. |

| Power Action | You need power to open it. | You need power to close it. |

| Best Use Case | Emergency shut-offs and standard flow control. | Systems that must vent pressure if power fails. |

| Safety | Fails closed (stops flow) during a power outage. | Fails open (allows flow) during a power outage. |

Most industrial applications I see rely on the normally closed NC configuration because it prevents leaks or spills if the electricity goes out. However, if your system needs to keep fluids moving to prevent overheating or pressure buildup during a blackout, the normally open NO is your go-to.

Would you like me to create a comparison guide for Direct-Acting vs. Pilot-Operated valves next?

Deep Dive into Solenoid Valve Actuation Methods

When I help customers choose a valve, the biggest confusion usually stems from how the valve actually opens. It’s not just about energizing a coil; the internal mechanics dictate whether the valve will work in your specific pressure environment. We categorize these into three distinct actuation types: direct acting, pilot operated, and semi-direct acting.

Direct Acting Solenoid

In a direct acting solenoid, the electromagnetic force is the only thing doing the work. When I energize the coil, the plunger armature is pulled directly off the orifice seat, allowing fluid to pass.

- Best Feature: It operates from 0 PSI. It does not need any line pressure to function.

- Limitation: Because the coil has to lift the seal against the full force of the fluid, the orifice size is generally small, and the flow rate (Cv factor) is lower.

- Use Case: I recommend these for low-flow applications, dispensing systems, or vacuum lines.

Pilot Operated Valve (Indirect Acting)

For larger pipes and higher pressures, a pilot operated valve is the industry standard. Instead of fighting the fluid pressure, this design uses it. The solenoid controls a tiny pilot port that vents pressure from the top of a diaphragm or piston. The line pressure then lifts the main seal for you.

- Best Feature: High flow capacity and high pressure rating with a relatively small, power-efficient coil.

- Limitation: It requires a minimum pressure differential (usually 3 to 5 PSI). If you have zero pressure in the line, this valve will not open.Do not use pilot valves on gravity-fed systems!

- Use Case: Ideal for irrigation, car washes, and industrial water control systems.

Semi-Direct Acting (Zero Differential)

The zero differential solenoid valve, or semi-direct acting, is a hybrid. The plunger is mechanically linked to the diaphragm. At low pressures, the coil lifts the diaphragm directly. At high pressures, the pilot function takes over to assist.

- Best Feature: It combines the zero-pressure operation of direct acting with the higher flow capabilities of pilot valves.

- Use Case: These are my top choice for gravity-fed systems or closed loops where pressure might drop to zero but you still need decent flow.

Quick Selection Guide:

| Actuation Type | Min. Pressure Required? | Flow Capacity |

|---|---|---|

| Direct Acting | No (0 PSI) | Low |

| Pilot Operated | Yes (Diff. Required) | High |

| Semi-Direct | No (0 PSI) | Medium/High |

Would you like me to create a comparison chart for common solenoid valve materials (Brass vs. Stainless Steel) for the next section?

Solenoid Valve vs. Motorized Ball Valve: Which to Choose?

A common dilemma for engineers is choosing between a solenoid valve and an electric ball valve. While both control flow electrically, they are beasts of different natures.

- Speed: Solenoids are instant (milliseconds), making them ideal for dosing. Motorized valves are slow (5-15s), which prevents water hammer.

- Media Purity: Solenoids clog easily in dirty water. If you are handling fluid with debris or need high flow rates, we recommend upgrading to a [Motorized Ball Valve].

- Power: Solenoids consume power constantly to hold position; motorized valves only use power while moving.

Types of Solenoid Valves by Circuit Function

When we talk about circuit function, we are really discussing the number of flow paths (ports) and the number of distinct states the valve can be in. In my experience supplying components for industrial automation control, understanding the difference between a simple shut-off valve and a complex directional control valve is crucial for building efficient systems.

Here is how we classify solenoid valves based on their circuit function.

2-Way Solenoid Valves: The Standard On/Off

This is the workhorse of the industry. A 2-way solenoid valve has one inlet port and one outlet port. It is designed for basic on/off control of fluids or gases.

- Function: It either allows fluid to flow through (open) or shuts it off (closed).

- Best Use: General-purpose shutting off of water, air, light oil, or gas lines. You will find these everywhere from irrigation systems to manufacturing lines.

3-Way Solenoid Valves: Diverting and Mixing

A 3-way solenoid valve introduces a third port, which usually functions as an exhaust or a secondary outlet. These are essential when you need to pressurize and exhaust a single-acting cylinder or divert flow between two different channels.

- NC vs. NO: Depending on the setup, these can be Normally Closed (NC), Normally Open (NO), or Universal (can handle flow in either direction).

- Best Use: Pilot control for larger valves, operating single-acting actuators, or diverting flow in chemical processing.

4-Way and 5-Way Solenoid Valves: Advanced Directional Control

When dealing with double-acting cylinders—where you need air to push a piston out and pull it back in—we step up to 4-way and 5-way valves. These are staples in pneumatic automation.

- 4-Way Valves: typically usually have four ports (one pressure, one exhaust, two cylinder ports). Common in hydraulic systems.

- 5-Way Valves: usually feature five ports (one pressure, two exhausts, two cylinder ports). These are the standard for pneumatic systems because having separate exhausts allows for better speed control on the extend and retract strokes.

- Best Use: Packaging machinery, assembly line robotics, and any application requiring precise industrial automation control of double-acting cylinders.

Quick Selection Guide: Circuit Functions

| Valve Type | Ports | States | Primary Function |

|---|---|---|---|

| 2-Way | 2 | 2 | On/Off Control |

| 3-Way | 3 | 2 | Diverting, Mixing, Single-Acting Cylinders |

| 4-Way | 4 | 2 or 3 | Hydraulic Cylinder Control |

| 5-Way | 5 | 2 or 3 | Pneumatic Cylinder Control |

Selecting the right circuit function ensures you aren’t over-engineering a simple line or under-speccing a complex automation task.

Classifications by Operating Principle and Material Selection

When we look at stocking or selecting the right solenoid valve for a project, it usually comes down to two main factors: how it handles pressure and what it’s made of. You can have the best electronics in the world, but if the body material dissolves in your media or the pressure principle is wrong, the valve will fail.

Operating Principles: Pressure Suitability and Trade-offs

Choosing between operating principles isn’t just about preference; it’s about the physics of your system. Here is how I break down the pros and cons based on pressure suitability:

- Direct Acting Solenoid Valves:

- Pros: These are my go-to for low-flow applications. The biggest selling point is that they are zero differential solenoid valves. This means they can operate from 0 PSI (vacuum) up to their rated maximum. They are fast and reliable.

- Cons: They require a larger, more powerful electromagnetic coil to open the orifice against higher pressures, which limits them to smaller sizes (usually under 1/2 inch).

- Pilot Operated (Indirect) Valves:

- Pros: These use the system’s own pressure to help lift the diaphragm or piston. This allows a small coil to control a huge amount of flow and very high pressures (often used in industrial automation control).

- Cons: They require a minimum pressure differential (usually around 5-10 PSI) to function. If you are using gravity feed, these won’t open.

Material Options for Fluid Compatibility

We see a lot of valve failures simply because the wrong material was chosen for the environment. In the US market, we generally categorize our valves into three main material groups to ensure proper fluid compatibility.

1. Brass Valves

This is the industry standard for neutral media.

- Best For: Water, air, light oil, and non-corrosive fluids.

- Why use it: It’s durable, handles heat well, and is cost-effective. If you are running a standard HVAC or irrigation setup, brass is usually the answer.

2. Stainless Steel (304 or 316)

When things get tough, we upgrade to stainless.

- Best For: Corrosive chemicals, food and beverage processing, and saltwater environments.

- Why use it: It offers superior resistance to corrosion and high temperatures. It’s also the standard for clean environments where hygiene is critical.

3. Plastic (PVC or Nylon)

Don’t underestimate plastic; engineered polymers are incredibly capable.

- Best For: Strong acids, alkalis, and cost-sensitive residential applications (like water purifiers).

- Why use it: Completely rust-proof and very cheap. However, they generally have lower temperature and pressure ratings compared to metal valves.

A Note on Seal Materials

The body material is only half the battle; the internal seals (the diaphragm solenoid component) dictate the real chemical resistance.

- NBR (Nitrile): Great for oil and petroleum.

- EPDM: Excellent for hot water and steam but terrible for oil.

- Viton (FKM): The premium choice for harsh chemicals and high heat.

What is the next step?

If you are unsure which material fits your specific chemical mix, would you like me to provide a quick compatibility chart for common US industrial fluids?

Specialized Solenoid Valve Types

Standard valves handle the basics just fine, but when my customers in the heavy industrial sector are dealing with extreme environments, “standard” doesn’t cut it. Sometimes, you need a valve built for specific, demanding scenarios. Here is a breakdown of the specialized gear we use when the stakes are high.

Proportional Solenoid Valves

Most solenoids are binary—they are either fully open or fully closed. But in sophisticated industrial automation control systems, you often need more finesse. Proportional valves adjust the flow rate based on a varying input signal (usually current or voltage). Instead of snapping the plunger armature all the way up, it holds it at precise points to regulate flow dynamically.

- Best for: Precise mixing, flow metering, and dynamic process control.

- Key Feature: Variable positioning rather than just On/Off.

High-Pressure Solenoid Valves

If you exceed the pressure rating of a general-purpose valve, you risk blowing out the seals or jamming the armature. Our high-pressure units are reinforced to handle massive PSI loads, often found in car wash systems or hydraulic applications. They typically use a piston design rather than a standard diaphragm solenoid to maintain integrity under stress.

Explosion-Proof Solenoid Valves

Safety is non-negotiable, especially in the oil and gas industries here in the States. When working with flammable gases or dust, a tiny spark from an electromagnetic coil can be catastrophic. Explosion-proof valves feature a specialized coil housing designed to contain any internal explosion without igniting the surrounding atmosphere.

- Certifications: Look for UL, ATEX, or IECEx ratings.

- Application: Refineries, chemical plants, and grain silos.

Key Applications in Industry and Automation

When we look at the backbone of American manufacturing and infrastructure, solenoid valves are the unsung heroes keeping everything moving. From massive assembly lines to the cooling systems in commercial buildings, these components are essential for precise, automated fluid control. In my experience, choosing the right valve for the specific job is what separates a smooth operation from costly downtime.

Here is how we see these valves powering the major sectors:

- Industrial Automation Control:In robotics and pneumatic systems, speed is everything. We use 4-way and 5-way solenoid valves to drive cylinders. These multi-port valves are the standard pilots for controlling [Pneumatic Actuated Valves], directing air to extend or retract the actuator with precision.

- Process Control: In chemical and pharmaceutical processing, accuracy is non-negotiable. Here, process control relies on proportional solenoid valves to regulate flow rates and mixtures exactly. Fluid compatibility is critical; we often use stainless steel bodies to handle aggressive chemicals without corrosion.

- HVAC and Refrigeration: Efficiency is the goal here. Solenoid valves manage the flow of refrigerants in chillers and air handling units. They control liquid lines and hot gas bypasses, often requiring a high pressure rating to handle modern refrigerants safely.

- Water Treatment: From municipal plants to industrial wastewater, diaphragm solenoid valves are standard for controlling dosing pumps and backwashing lines.

- Pro Tip: For large-diameter main lines (>2 inches) where solenoids become too expensive or bulky, we typically switch to [Wafer Butterfly Valves] for efficient isolation.

Would you like me to help you create a checklist for selecting the right valve based on your specific media and pressure requirements?

Commercial and Consumer Solenoid Valve Applications

You might assume solenoid valves are strictly for massive industrial plants, but that isn’t the case. I see these components working hard in places you visit every day and even inside your own home. Whether it’s keeping your car running smooth or ensuring your laundry gets done, these valves are the silent workhorses managing flow control behind the scenes.

Here is a breakdown of how we apply this technology across different commercial and consumer sectors:

- Automotive Industry: Inside your vehicle, solenoid valves are critical for performance and safety. We use them in fuel injection systems to dose fuel precisely and in automatic transmissions to manage hydraulic fluid. They have to withstand high temperatures and vibration while maintaining a strict pressure rating.

- Medical Equipment: In the medical field, reliability is a matter of life and death. You will find miniature valves in dialysis machines, blood analyzers, and anesthesia delivery systems. Here, fluid compatibility is the top priority to prevent contamination.

- Food Processing and Dispensing: Ever wonder how a soda fountain mixes your drink perfectly? That’s a solenoid at work. In commercial coffee machines and food processing lines, we use food-grade valves (often stainless steel) to control water, steam, and syrups hygienically.

- Oil and Gas (Commercial): Beyond the oil rig, we use robust valves at gas stations and in commercial heating systems. They act as essential safety shut-offs to prevent leaks of hazardous fuels.

- Household Appliances: This is the most common place you’ll find them. In household appliances like washing machines and dishwashers, a simple plastic diaphragm solenoid valve controls the water inlet. When the machine calls for water, the valve opens; when the tub is full, it snaps closed.

In these applications, the goal isn’t just heavy lifting; it’s about precision, safety, and longevity. Whether we are dealing with AC or DC voltage inputs, selecting the right valve ensures that your daily equipment runs without a hitch.

Next Step

Would you like me to create the next section on “How to Select the Right Solenoid Valve” to help you choose the correct specs for these applications?

How to Select the Right Solenoid Valve

Choosing the correct solenoid valve isn’t just about matching a part number; it’s about ensuring safety and efficiency in your system. In my experience, overlooking a single variable here usually leads to leaks, coil burnout, or a valve that simply refuses to actuate. Whether you are dealing with industrial automation control or a simple home project, you need to match the valve specs to your specific operating conditions.

Here is the checklist I use to ensure we get the right fit every time:

- Fluid Compatibility and Materials:

Always start with the media. What are you controlling—water, oil, steam, or corrosive chemicals? You need to match the valve body (Brass, Stainless Steel, or Plastic) and seal materials (NBR, EPDM, or Viton) to the fluid. Using a standard brass valve for corrosive acids is a recipe for failure. - Pressure Rating (MOPD):

Check your pressure range carefully. You must know the Maximum Operating Pressure Differential (MOPD) and the minimum pressure. For gravity-fed systems or low-pressure lines, you must use a direct acting solenoid or a zero differential solenoid valve. A pilot operated valve requires system pressure to lift the diaphragm and will not work in these scenarios. - Cv Flow Factor and Orifice Size:

Don’t select a valve based solely on the port size (e.g., 1/2 inch). You need to calculate the required Cv flow factor, which determines the valve’s capacity based on the internal orifice size. Undersizing creates a bottleneck, while oversizing is unnecessarily expensive. - AC/DC Voltage Specifications:

Ensure the coil voltage matches your power supply (e.g., 12V DC, 24V DC, 120V AC, or 220V AC). Keep in mind that AC/DC voltage choices affect performance; AC coils generally have a higher in-rush current providing strong opening force, while DC coils run quieter and cooler. - Temperature Ratings:

Consider both the fluid temperature and the ambient environment. High-temperature applications (like steam) often require PTFE seals and Class H coils to prevent overheating.

Solenoid Valve Maintenance and Troubleshooting

Trust me, nothing kills a system faster than a neglected valve. If you want your automation or fluid control systems to last, you have to stay on top of maintenance. In my experience, most failures come down to three things: dirt, heat, and worn-out seals.

Routine Maintenance Checks

You don’t need a PhD to keep these running. Here is the checklist I use to catch problems before they shut down production:

- Listen to the sound: A healthy valve makes a sharp “click” when energized. A loud buzzing (especially in AC valves) usually means the electromagnetic coil is failing or debris is trapped on the pole face.

- Clean the internals: Most failures happen because of sediment. Periodically clean the orifice and diaphragm to prevent clogging.

- Inspect the Seals: Look for cracks or swelling in the O-rings. If your fluid isn’t compatible with the seal material, it will degrade fast.

Common Troubleshooting Scenarios

If your system is down, don’t panic. Here is how I handle the most common headaches.

The Coil is Overheating

If you are dealing with solenoid valve troubleshooting coil hot to the touch, you likely have a voltage mismatch or a short circuit.

- Check the Voltage: Ensure you aren’t feeding the wrong AC/DC voltage (like 24V into a 12V coil).

- Inspect the Plunger: If the plunger armature is stuck and doesn’t pull all the way up, the inrush current stays high and will eventually burn out the coil.

Leakage or Failure to Close

If the valve is leaking internally, it’s usually debris stuck between the seal and the seat or a damaged diaphragm.

- Action: Disassemble the valve, clean the pilot hole, and check the spring tension. If the rubber components are torn, swap them out immediately.

Quick Troubleshooting Reference:

| Symptom | Probable Cause | Quick Fix |

|---|---|---|

| Valve won’t open | Low voltage, burnt coil, or pressure too high | Test coil resistance; verify pressure rating. |

| Valve won’t close | Dirt in the orifice or broken spring | Clean the armature tube; replace the spring. |

| Loud Buzzing | Debris on the magnetic core | Clean the top of the stationary core. |

| Sluggish Operation | High viscosity fluid or low differential pressure | Verify fluid compatibility and Cv flow factor. |

- PREV: Gate Valve Guide: Working Principles, Types & Uses (2026)

- NEXT: Not NEXT

Contact Us

In This Article

Solenoid Valve Guide: Working Principle, Types & Applications

Dec 30, 2025

Gate Valve Guide: Working Principles, Types & Uses (2026)

Dec 30, 2025

Wafer Butterfly Valve: Working Principle, Types & Advantages Guide

Dec 29, 2025

Motorized Ball Valve: The Complete Guide to Types, Wiring, and Selection

Dec 29, 2025