Home /

Home / What Is a Valve: A Complete Guide to Types, Parts, Functions, and Selection

What Is a Valve: A Complete Guide to Types, Parts, Functions, and Selection

Dec 26, 2025

Different Types of Valve Actuators Working Principles and Benefits

Nov 29, 2025

Pneumatic Control Valves Overview Advantages and Industrial Applications

Nov 29, 2025

Ball Valve Maintenance Guide Preventive Routine Procedures 2026

Nov 29, 2025

When people ask me “what is a valve?” they’re really asking one thing: how does this device actually control my fluid and protect my system? In every industrial piping system, valves do four core jobs:

Basic Functions of Valves in Piping Systems

When people ask me “what is a valve?” they’re really asking one thing: how does this device actually control my fluid and protect my system? In every industrial piping system, valves do four core jobs:

Core Valve Functions in Piping Systems

At the simplest level, valves control the flow of liquids, gases, or steam by changing the size of the flow passage. In real plants, that turns into four main functions:

- Isolation (On/Off / Shut-off valves)

- Fully open or fully closed

- Used to start, stop, or segment flow in a line

- Critical for maintenance, emergency shutdown, and system startup

- Throttling (Flow control valves)

- Partially open to regulate flow rate or pressure

- Used when you need stable, repeatable process control

- Common in control valves, globe valves, and needle valves

- Non-Return (Check valves / Backflow prevention)

- Let flow go one way only

- Close automatically if flow tries to reverse

- Protect pumps, compressors, and equipment from backflow damage

- Pressure Relief (Overpressure protection valves)

- Open automatically when pressure gets too high

- Protect vessels, piping, and equipment from overpressure

- Core safety layer in boilers, process plants, and high-pressure systems

How Valves Impact Safety, Efficiency, and Process Control

In real-world piping systems, the right valve selection is not just a design choice—it’s a risk and money decision:

- Safety

- Reliable isolation valves prevent leaks during maintenance

- Pressure relief valves and safety valves stop catastrophic failures

- Non-return valves prevent reverse flow that can crack pipes or destroy pumps

- Efficiency

- Proper flow control valves reduce energy waste from over-pumping

- Correct valve sizing and type lower pressure drop and operating cost

- Tight shut-off valves stop product loss and unmetered flow

- Process Control

- Good throttling valves keep flow, temperature, and pressure stable

- Smooth, predictable valve actuation improves automation performance

- The right valve type and trim helps avoid cavitation, noise, and vibration

In short, a valve is more than a piece of hardware. It’s the control point that decides how safe, efficient, and controllable your entire piping system really is.

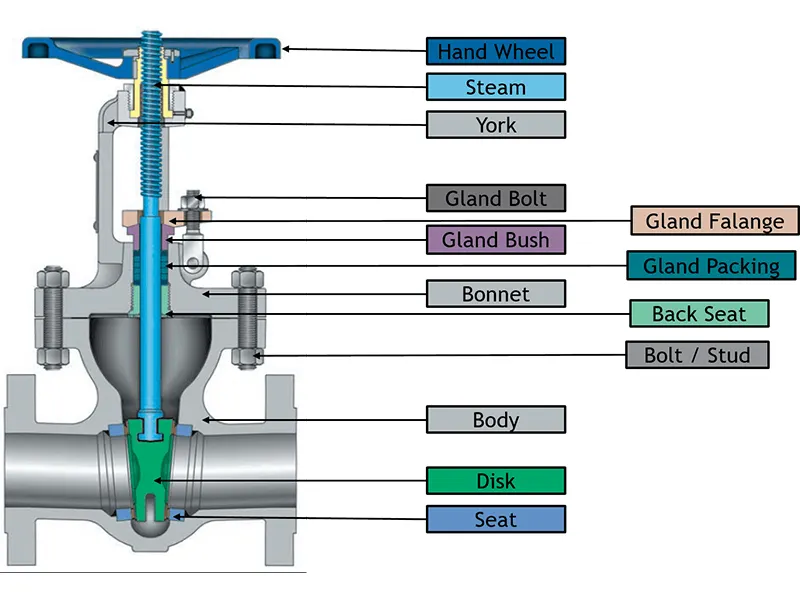

Key Parts of a Valve and Their Functions

Understanding valve parts and functions makes it much easier to pick, install, and maintain the right valve in commercial building. Here’s the quick breakdown.

Valve Body and Flow Path

The valve body is the main pressure-containing shell.

- Forms the flow path the fluid travels through

- Provides the end connections (flanged, threaded, welded)

- Built from carbon steel, stainless, or specialty alloys depending on pressure, temperature, and corrosion needs

In industrial service, I typically match body materials to piping specs and media to avoid premature failure.

Bonnet and Pressure Boundary

The bonnet bolts or threads onto the body and closes the top opening.

- Completes the pressure boundary

- Supports the stem, packing, and sometimes the actuator

- Must be rated for the same pressure class as the body

Poor bonnet gaskets or bolting are one of the fastest ways to end up with external leaks.

Valve Trim: Disc, Seat, and Stem

The trim is everything inside the valve that actually controls flow:

- Disc/ball/plug – the moving part that blocks or throttles flow

- Seat – the sealing surface the disc presses against

- Stem – connects the disc to the handwheel or actuator

For critical shutoff or control, I always look at trim materials and hardness first—they take the brunt of erosion and cavitation.

Actuators and Manual Operators

Valves can be manual or automatic:

- Manual operated valves: typically equipped with a handwheel, lever, or gear operator for cost-effective isolation.

- Actuators: Actuators: electric actuated valves for precise control or pneumatic actuated valves for fast, fail-safe operation in process plants.

On bigger lines and high-torque valves (like large butterfly or ball valves), we’ll pair them with robust actuators similar to those used on industrial quarter‑turn valves and control products.

Packing, Seals, and Leakage Control

Packing and seals protect against leaks to atmosphere:

- Stem packing (graphite, PTFE, etc.) seals around the stem

- Gaskets and O‑rings seal body‑to‑bonnet and other joints

- Proper compression keeps fugitive emissions and product loss in check

If I see stem leakage, packing adjustment or replacement is the first thing I check.

Supporting Parts: Yoke, Gland, Handwheel

These parts keep everything aligned and operable:

- Yoke – rigid frame that supports the actuator or handwheel above the bonnet

- Gland and gland flange – compress the packing to maintain a tight seal

- Handwheel or lever – the user interface for manual operation

Even on basic on/off valves, a sturdy yoke and properly set gland make a noticeable difference in reliability and feel when you operate the valve.

Valve Classification Overview: What Is a Valve and How Do We Group Them?

When I talk with U.S. plant managers, maintenance techs, or contractors, I always start by classifying what a valve is in simple groups. That makes choosing the right valve for a piping system much easier.

Linear vs Rotary Motion Valves

From a motion standpoint, most industrial valve types fall into two buckets:

- Linear motion valves (stem moves straight up/down)

- Common: gate valves, globe valves, diaphragm valves, needle valves

- Best for: tight isolation, throttling, and pressure control where precise stem travel matters

- Rotary motion valves (quarter-turn or similar rotation)

- Common: ball valves, butterfly valves, plug valves

- Best for: fast on/off, compact design, automation with simple actuators

Knowing if you need linear motion or rotary motion helps narrow valve selection fast.

| Feature | Linear Motion Valves | Rotary Motion Valves |

|---|---|---|

| Common Examples | Gate, Globe, Diaphragm, Needle | Ball, Butterfly, Plug |

| Stem Movement | Stem moves up and down (Push/Pull) | Stem rotates 90 degrees (Quarter-turn) |

| Operation Speed | Slow (Multi-turn handwheel) | Fast (Handle or pneumatic actuator) |

| Throttling Ability | Excellent (Especially Globe/Needle) | Limited (Except special V-port balls) |

| Headroom Needed | High (Stem rises up) | Low (Compact design) |

| Typical Actuator | Diaphragm or Piston Linear Actuator | Rack & Pinion or Electric Rotary Actuator |

Isolation, Control, Check, and Relief Valve Groups

I classify piping system valves by what job they do:

- Isolation (on/off) valves

- Gate, ball, plug, butterfly

- Used for shut off valve types where you want full open or full closed

- Control (throttling / flow control valves)

- Globe, diaphragm, needle, control valves with actuators

- Used for flow control, pressure control, and process tuning

- Check valves (non-return valves)

- Swing check, lift check, wafer check

- Stop backflow automatically, no operator needed

- Pressure relief / safety valves

- Pressure relief valve and safety valve types

- Protect equipment and people from overpressure

These four groups line up closely with real-world U.S. plant standards and code requirements.

End Connections: Flanged, Threaded, Welded

End connections on valves in piping systems matter for cost, safety, and maintenance:

- Flanged valves

- Easy to remove and service

- Common in refineries, chemical plants, water treatment

- Standard choice for medium–large pipe sizes

- Threaded (screwed) valves

- Used for small diameter lines (typically up to 2″)

- Common in commercial buildings, light industrial, HVAC, and plumbing

- Welded (butt weld / socket weld) valves

- Strong, leak-tight for high pressure valves and high temperature systems

- Typical in oil & gas, power plants, and critical service where you don’t want joints loosening

I match connection type to pressure rating, pipe size, and how often the valve may need to come out.

Valve Materials and Service Conditions

Valve material choices have to fit the service conditions in the U.S. market:

- Carbon steel

- Go-to for general industrial service, steam, oil, and gas

- Good for higher pressures and moderate temperatures

- Stainless steel

- Better corrosion resistance for chemicals, food & beverage, and clean services

- Common when media is corrosive, or cleanliness is key

- Bronze / brass

- Widely used in commercial plumbing and marine valve applications due to excellent resistance to seawater corrosion.

- Easy to machine and cost-effective

- Special alloys / lined valves

- For slurry service valves, aggressive chemicals, or extreme temperatures

- Think PTFE-lined, Hastelloy, duplex stainless, etc.

| Material | Common Grade | Best Applications | Temp/Pressure | Cost |

|---|---|---|---|---|

| Brass / Bronze | C37700 / B62 | Plumbing, HVAC, Low-pressure Water/Gas. | Low / Low | $ |

| Carbon Steel | A216 WCB | Oil & Gas, Steam, High-pressure Industrial. | High / High | $$ |

| Stainless Steel | A351 CF8M (316) | Chemicals, Food & Bev, Corrosive environments. | High / High | $$$ |

| Cast Iron | A126 Class B | Waterworks, Wastewater, General purpose. | Low / Low | $ |

| PVC / CPVC | Sch 80 | Chemical processing, Water treatment, Pools. | Low / Low | $ |

When I select a valve, I always match pressure, temperature, media, and corrosion to the right body material, trim material, and end connection. That’s the core of good valve selection criteria and long-term reliability in real U.S. plants and buildings.

Common Types of Valves Explained

When I pick a valve for a U.S. facility or plant, I usually start with these core industrial valve types. Each one shines in a specific job: isolation, throttling, non‑return, or pressure relief.

Gate valves and full-bore shutoff

What they do:

- Classic on/off shut-off valve for water, oil, gas

- Full-bore opening – almost no pressure drop when fully open

- Best for lines that stay either fully open or fully closed

Where I use them:

- Main isolation valves on straight piping runs

- Fire water lines, utility water, low-cycle services

Avoid for: precise flow control; they’re slow and rough for throttling.

Globe valves and throttling control

What they do:

- Designed for throttling and flow control

- More pressure drop, but better control than gate valves

- Commonly used as globe control valves in critical process lines where precise flow regulation is required.

Where I use them:

- Steam, condensate, cooling water bypasses

- Anywhere I need repeatable flow adjustment

Ball valves and quarter-turn operation

What they do:

- Quarter-turn valves: 90° from fully open to fully closed

- Tight shutoff, fast operation, low pressure drop

- Great as on/off valves in most U.S. industrial and commercial systems

Where I use them:

- Compressed air, gas, fuel, water, utilities

- Skid packages, OEM equipment, building piping

Butterfly valves for large lines

What they do:

- Rotary motion valves with a disc in the pipe center

- Compact, light, cost-effective in large diameters

- Can be used for on/off and moderate throttling

Where I use them:

- HVAC chilled water, cooling towers, large process lines

- Big diameter

| Valve Type | Primary Function | Best For | Pros | Cons |

|---|---|---|---|---|

| Gate Valve | Isolation (On/Off) | Main water supply, large pipelines where flow is constant. | Full flow, low pressure drop, bidirectional. | Slow to operate, not for throttling. |

| Globe Valve | Throttling (Control) | Steam systems, cooling water flow regulation. | Excellent flow control, easy maintenance. | High pressure drop, more expensive. |

| Ball Valve | Isolation (On/Off) | Gas lines, residential water, chemical plants. | Fast 1/4 turn, tight sealing, durable. | Poor throttling control, trapped cavity fluid. |

| Butterfly Valve | Isolation & Throttling | Large diameter HVAC, water treatment. | Lightweight, compact, low cost. | Seat wear, less precise control than globe. |

| Check Valve | Backflow Prevention | Pump discharge, vertical headers. | Automated protection, no operator needed. | Can chatter if undersized, added friction. |

How Does a Valve Work in Real Systems?

When I design or select valves for a U.S. plant or building system, I focus on how the valve type, motion, and actuator will actually control flow in the real world.

Flow control principles by valve type

Different industrial valve types move the flow in different ways:

- On/off (isolation) valves – gate, ball, plug:

- Designed to be fully open or fully closed

- Low pressure drop when open

- Not ideal for fine throttling

- Flow control (throttling) valves – globe, needle, control valves:

- Let you adjust flow rate precisely

- Great for process control and HVAC balancing

- Non-return valves (check valves):

- Open with forward flow, close on backflow

- Protect pumps, compressors, and equipment

- Pressure relief valves:

- Open automatically at a set pressure

- Protect piping and tanks from overpressure

Linear lift: gate and globe valve operation

Linear motion valves use a stem that moves straight up and down:

- Gate valve operation

- Stem lifts a “gate” out of the flow path

- Full-bore opening for minimal pressure drop

- Best for shut-off, not for regular throttling

- Globe valve operation

- Disc moves down onto a seat to restrict flow

- Flow changes in a controlled, predictable way

- Ideal for flow control valves in process and utility lines

This style is common in high-pressure steam, water, and process piping in U.S. industrial plants.

Rotary motion: ball, butterfly, and plug valves

Rotary motion valves turn 90° (quarter-turn) to open or close:

- Ball valves

- Drilled ball aligns with the pipe for full open

- Quarter-turn for fast shut-off

- Very common in U.S. commercial and residential piping systems

- Butterfly valves

- Disc rotates in the flow stream

- Lightweight, great for large-diameter HVAC and water lines

- Moderate throttling capability

- Plug valves

- Tapered or cylindrical plug with a port

- Good for on/off and some throttling in dirty or corrosive service

These rotary motion valves pair well with compact actuators and are easy to automate.

Manual vs automated valve actuation methods

In real facilities, I mix manual valves and automatic valves for cost and control:

- Manual actuation

- Handwheel, lever, or gear operator

- Best for low-cycle, non-critical service

- Lower cost, simple to maintain

- Automated actuation

- Electric actuators – great for building automation, remote control

- Pneumatic actuators – standard in process plants, fast and reliable

- Hydraulic actuators – used on large or high-torque valves

- Often combined with positioners, limit switches, and solenoids for precise control

Choosing the right valve actuation methods is a core part of any valve selection guide in U.S. industry.

Basic P&ID symbols for common valves

On P&ID drawings, valves are simplified but consistent:

- Gate valve – simple rectangle or gate symbol in the line

- Globe valve – symbol with a “bulged” body in the line

- Ball valve – circle with a quarter-turn mark

- Butterfly valve – circle with a line (disc) across it

- Check valve (non-return valve) – valve symbol with an arrow “flap”

- Pressure relief valve – spring-loaded symbol venting to a relief line

- Control valve – globe-style symbol with a diagonal line or actuator bubble

Learning these P&ID symbols makes it much easier to read U.S. plant drawings, spot flow control valves, and troubleshoot common valve problems in real piping systems.

Valve Selection Guide for Real-World Applications

When I pick a valve for a U.S. plant or commercial building, I always start with the process, not the catalog. A valve that’s “good enough” on paper can still fail fast in the field if the basics are wrong.

Reading Your Process Conditions

Before choosing any industrial valve type, lock in these details:

- Fluid type: clean liquid, gas, steam, slurry, corrosive chemical, abrasive fluid

- Operating pressure: normal, minimum, and maximum pressure (including surges)

- Temperature range: startup, normal, and upset conditions

- Required function: isolation, throttling / flow control, non-return (check), or pressure relief

- Piping layout: line size, schedule, end connections, space for operation and maintenance

Write these down. Every valve decision flows from these numbers.

Matching Valve Type to Fluid and Service

Here’s how I generally match valve types to common U.S. applications:

- Gate valve: on/off isolation, full-bore, low pressure drop, not for fine throttling

- Globe valve: flow control valve for throttling and regulating, good for control valves

- Ball valve: fast quarter-turn on/off valve, great shutoff, widely used in HVAC, water, oils, gas

- Butterfly valve: large diameter lines, low weight, good for HVAC, cooling water, low/medium pressures

- Check valve (non-return valve): stops backflow in pumps and header lines

- Diaphragm valve: corrosive or slurry service, wastewater, chemical dosing

- Plug valve / needle valve: on/off with some throttling (plug), fine flow control (needle)

- Pressure relief / safety valve: overpressure protection on boilers, compressors, pressure vessels

If the main goal is tight isolation, I lean toward ball or gate valves. If the priority is precise throttling, I go globe or specialty control valves.

Pressure, Temperature, and Flow Requirements

To keep a valve safe and reliable in real-world service:

- Pressure rating: use ASME class or PSI rating that covers worst-case pressure

- Temperature limits: check body, trim, and packing temperature ranges

- Flow characteristics:

- High flow, low drop → ball, gate, butterfly

- Modulating control → globe or characterized ball valves

- Cv / Kv sizing: size the valve to the required flow, not just the pipe size

Oversizing is a common U.S. industry problem. A valve that’s too big will “hunt,” wear fast, and control poorly.

Corrosion, Erosion, and Material Compatibility

Valve materials must match your fluid and environment:

- Carbon steel / ductile iron: standard water, oil, gas, HVAC, and general industrial service

- Stainless steel: corrosive fluids, food & beverage, pharma, chemical service

- Alloys (Duplex, Hastelloy, etc.): aggressive chemicals, offshore, high chloride service

- Elastomers / soft seats (PTFE, EPDM, Viton): check compatibility with chemicals and temperature

For abrasive or slurry service in U.S. mining, wastewater, or pulp applications, I favor hardened trim, diaphragm valves, or special slurry valves to fight erosion.

Choosing the Right Actuator and Accessories

Once the valve is right, I match the actuator to the job:

- Manual (handwheel, lever): low-cost, low cycle, easy access

- Electric actuator: precise positioning, integration with building automation or PLC, indoor-friendly

- Pneumatic actuator: fast, fail-safe (fail-open or fail-closed), widely used in process plants

- Hydraulic actuator: high torque for large or high-pressure valves

Useful accessories for U.S. facilities:

- Limit switches / positioners for automation and feedback

- Solenoid valves for pneumatic control

- Locking devices for safety and lockout/tagout compliance

Common Valve Selection Mistakes to Avoid

I see the same errors over and over. I avoid them like the plague:

- Using a gate valve for throttling → seat damage and leaks

- Choosing the wrong valve material for corrosive or hot service

- Ignoring valve actuation torque and picking an undersized actuator

- Forgetting about maintenance access (valve ends up buried behind equipment)

- Skipping pressure relief valves on closed systems → overpressure risk

- Assuming “one valve fits all” instead of matching valve to service and process conditions

If you start with the process, match the valve type to the function, then dial in materials and actuation, you’ll end up with a valve that actually works in your piping system and doesn’t become a maintenance headache six months later.

Valve Installation, Maintenance, and Troubleshooting

Best practices for valve installation in piping

When I install a valve in a piping system, I’m thinking long-term reliability first:

- Check the spec: Match valve type, pressure rating, end connections, and materials to the line (no guessing on pressure/temperature).

- Support the piping: Never use the valve as a pipe support. Use proper pipe supports so the valve body and bonnet aren’t stressed.

- Clean the line: Flush debris before installing. Dirt will ruin valve trim, seats, and packing fast.

- Install in the right direction: Follow flow arrows on check valves, control valves, and pressure relief valves.

- Use proper gaskets and torque: Tighten flanged joints in a star pattern to avoid body distortion and leaks.

- Respect orientation: Some valves (especially check valves and relief valves) need vertical or specific mounting positions to work properly.

Routine inspection, lubrication, and testing

A solid valve maintenance checklist keeps downtime and leaks under control:

- Visual inspection: Look for body and bonnet corrosion, packing leaks at the stem, and any wet spots on flanges.

- Cycle the valve: Operate manual and automatic valves fully open/closed to avoid sticking and verify stroke.

- Lubricate where required: Grease gear operators, stems (if design allows), and actuators according to OEM instructions.

- Test safety and pressure relief valves: Follow code and site procedures for pop testing and set pressure verification.

- Log everything: Record valve tag, location, last service, and any issues so future troubleshooting is faster.

Dealing with leaks, sticking, and wear

Most common valve problems in U.S. plants, building systems, and industrial sites come down to a few patterns:

- External leaks (packing/flanges)

- Gently tighten gland nuts evenly.

- If leak continues, replace packing or gaskets with compatible materials.

- Internal leakage (won’t shut off)

- Check for damaged seat, disc, or ball – solids, corrosion, and erosion are usual suspects.

- Inspect valve trim and clean or replace worn components.

- Sticking or hard-to-operate valves

- Look for bent stems, buildup on seats, dried-out lubrication, or misaligned actuators.

- Clean, re-lube, and verify the actuator is sized and set correctly.

- Vibration and noise

- Common in throttling and high-pressure drop services; may require a different valve type or trim.

When to repair vs when to replace

I treat valves like any other critical asset: run the numbers and the risk.

Repair the valve when:

- The body and bonnet are sound (no deep corrosion or cracking).

- The problem is limited to trim, packing, or actuators.

- It’s a large, specialty, or high-pressure valve where parts are cheaper than a full replacement.

Replace the valve when:

- The body is thinned, cracked, or heavily corroded.

- It’s undersized, oversized, or simply the wrong valve type for the service (for example, using a gate valve for constant throttling).

- The cost of repeated repair plus downtime is higher than installing a new modern design.

- Codes or safety standards require upgrading, especially for pressure relief valves and critical flow control valves.

Smart valve installation, proactive maintenance, and clear troubleshooting steps are what keep flow control stable, protect equipment from overpressure, and avoid surprise shutdowns in real-world U.S. piping systems.

Valve FAQs and Quick Answers

Common questions on valve types and uses

Q: What is a valve in a piping system?

A: A valve is a mechanical device that starts, stops, or controls the flow of a fluid (water, gas, steam, chemicals) in a pipe. In U.S. plants and commercial buildings, valves are used for isolation, throttling, non‑return (check), and pressure relief.

Q: Which valve is best for simple on/off service?

A: For most industrial and commercial jobs in the U.S., I typically pick ball valves or gate valves for on/off (shut off) service, depending on line size, pressure, and budget.

Q: Which valves are best for flow control (throttling)?

A: Globe valves, butterfly valves, plug valves, and dedicated control valves are better for flow control valves applications than gate valves.

Gate valve vs globe valve use cases

Gate valve (on/off, isolation valve):

- Use when:

- You need full-bore flow (minimal pressure drop)

- The valve stays mostly fully open or fully closed

- You’re isolating pumps, tanks, or long pipe runs

- Do not use for: Precise throttling or frequent cycling

Globe valve (throttling and control):

- Use when:

- You need accurate flow control or pressure control

- The valve will be adjusted often

- You’re controlling steam, condensate, hot water, or process fluids

- Downside: Higher pressure drop than a gate valve

Simple rule of thumb (USA plants and commercial jobs):

- Need clean shutoff, low pressure loss → pick a gate valve or ball valve

- Need controlled flow or pressure → pick a globe valve or control valve

Picking an actuator for your valve

Q: How do I choose a valve actuator?

I look at five things:

- Power source available

- Manual: Handwheel or lever for small/low-duty valves

- Electric actuator: Good for building systems, remote control, and slow operation

- Pneumatic actuator: Common in process plants for fast, fail-safe control

- Hydraulic actuator: For high-pressure valves or where strong force is needed

- Fail position (safety)

- Need it to go fail-closed or fail-open on loss of power/air?

- Pneumatic spring-return actuators are typical for fail-safe setups.

- Torque or thrust

- Ball, butterfly, plug = rotary motion valves → need torque

- Gate, globe, needle = linear motion valves → need thrust (linear actuator)

- Speed of operation

- Emergency shutdown (ESD) → faster pneumatic

- Gentle operation to avoid water hammer → slower electric

- Environment

- Outdoor, corrosive, or hazardous area → choose the proper enclosure rating and materials

Basic valve troubleshooting questions and answers

Q: Why is my valve leaking at the stem?

A: Most of the time, it’s packing:

- Try slightly tightening the packing gland

- If that doesn’t work, replace the stem packing with the right temperature/chemical-rated material

- Check for a scratched or bent stem

Q: The valve won’t fully close. What now?

A: Common valve problems:

- Debris stuck in the seat – cycle the valve or flush the line

- Worn trim (seat/disc/ball/plug) – inspect and replace trim

- Misadjusted or weak actuator – check travel stops and calibration

Q: The actuator is moving, but flow isn’t changing.

A: Likely issues:

- Stem not coupled to the actuator properly

- Sheared pin, stripped threads, or loose linkage

- Wrong rotation or stroke setting on the actuator

Q: My check valve is chattering or noisy.

A: That usually means:

- Flow is too low for that check valve type

- Spring or disc is too heavy for your normal flow conditions

- You may need a spring-loaded or silent check valve sized for your actual flow, not just pipe size

| Symptom | Likely Cause | Quick Fix |

|---|---|---|

| Stem Leakage | Worn packing or loose gland nuts. | Tighten gland nuts slightly or replace packing. |

| Passing (Internal Leak) | Debris in seat or damaged disc/ball. | Flush line fully open; inspect trim for damage. |

| Hard to Operate | Dried lubricant, bent stem, or corrosion. | Lubricate stem/gearbox; check for stem alignment. |

| Water Hammer | Closing valve too fast (esp. quarter-turn). | Install slow-closing actuator or shock arrestor. |

| Noise / Vibration | Cavitation or undersized valve. | Check sizing (Cv) and pressure drop; install correct trim. |

These fast checks solve most everyday valve troubleshooting calls I see in U.S. facilities and mechanical rooms.

- PREV: Different Types of Valve Actuators Working Principles and Benefits

- NEXT: Not NEXT

Contact Us

In This Article

What Is a Valve: A Complete Guide to Types, Parts, Functions, and Selection

Dec 26, 2025

Different Types of Valve Actuators Working Principles and Benefits

Nov 29, 2025

Pneumatic Control Valves Overview Advantages and Industrial Applications

Nov 29, 2025

Ball Valve Maintenance Guide Preventive Routine Procedures 2026

Nov 29, 2025