Home /

Home / Electric Butterfly Valve Guide Features Types and Selection Tips

Comprehensive Electric Butterfly Valve Guide covering types, materials, actuator control, installation tips, and industry applications for optimal flow control.

Are you struggling to automate your flow control without blowing your budget?Selecting the right Electric Butterfly Valve is the difference between a seamless system and a maintenance nightmare.

I’ve seen too many industrial projects fail because of ignored torque safety margins or incompatible seat materials.In this Electric Butterfly Valve Guide, you’re going to learn exactly how to spec, size, and install these units correctly.

We aren’t just covering definitions.We are diving into modulating control, failsafe options, and how to avoid the “Torque Trap” that destroys actuators.

Here is everything you need to know to master flow automation.Let’s dive in.

Introduction to Electric Butterfly Valves

What is an Electric Butterfly Valve?

An electric butterfly valve is a vital component in modern automation, combining a mechanical quarter-turn valve with an electric actuator to manage fluid flow control. These valve assemblies are designed to regulate or isolate the flow of liquid and gas within industrial piping systems. From HVAC loops to complex wastewater operations, these electrically actuated units replace manual labor with automated precision, ensuring consistent performance across diverse media.

Working Principle: From Rotary Motion to Flow Control

The mechanism relies on converting electrical energy into mechanical rotary motion. The electric actuator drives the valve stem, which rotates the butterfly plate (or disc or vane) positioned in the center of the pipe.

- Open Position: The disc aligns parallel to the flow, allowing media to pass with minimal resistance.

- Closed Position: The disc rotates 90 degrees to sit perpendicular to the flow, sealing tightly against the ring seat.

- Modulation: Intermediate angles allow for flow regulation, adjusting the volume passing through the valve.

The “Quarter-Turn” Advantage: Why It Beats Gate Valves

The primary advantage of this design is the quarter-turn operation. While traditional gate valves require multiple turns of a handwheel to operate, a butterfly valve moves from fully open to fully closed with just a 90-degree rotation.

- Speed & Efficiency: Faster actuation times are crucial for emergency shutdowns and rapid process changes.

- Throttling Capability: Unlike gate valves, which are strictly on/off, electric butterfly valves can function as throttling valves for precise control.

- Compact Footprint: They are lighter and occupy less space, reducing stress on the pipeline.

Electric Actuator Essentials: The “Brain” of the Valve

When we engineer automated valve assemblies, the electric actuator serves as the command center. It replaces manual levers, converting electrical energy into rotary motion to drive the valve stem. Choosing the correct actuator type is just as critical as selecting the valve body itself, ensuring the torque output matches the application’s resistance.

On-Off vs. Modulating Control: 4-20mA Signals and Precision

We categorize electrically actuated systems based on how they manage flow. The choice depends on whether you need simple isolation or dynamic flow regulation.

- On-Off Control: The standard for isolation. The motor drives the butterfly plate to a fully open or fully closed position. It is ideal for “shut-off” services where precise control isn’t required.

- Modulating Control: These units accept an analog signal (typically 4-20mA or 0-10V DC). This allows the actuator to position the disc at specific angles (e.g., 25%, 50%, 75%) for accurate throttling in fluid control systems.

Comparison of Control Types:

| Feature | On-Off Actuators | Modulating Actuators |

|---|---|---|

| Function | Isolation (Open/Close) | Throttling (Flow Regulation) |

| Signal | Power Supply Voltage | 4-20mA / 0-10V Control Signal |

| Application | Pump discharge, Shut-off | Temperature control, Mixing |

| Cost | Lower | Higher |

Failsafe Options: Battery Backup vs. Capacitor Return (Addressing Safety)

In industrial piping systems, power failure is a real risk. Standard electric actuators stay in their last position when power acts out. For critical safety, we recommend failsafe options:

- Battery Backup: An internal battery pack drives the valve to a safe position (open or closed) during an outage.

- Capacitor Return: Uses stored energy in supercapacitors to perform the failsafe return. This is often preferred for high-cycle applications as it requires less maintenance than chemical batteries.

Voltage (AC/DC) and NEMA/IP Ratings for Outdoor Use

We stock actuators with various voltage options to match global site infrastructure. Ensuring the actuator enclosure can withstand the environment is vital for longevity.

Common Voltage Options:

- AC Voltages: 110V, 220V, 380V, 440V (Common in heavy industrial plants).

- DC Voltages: 12V, 24V (Often used in remote or solar-powered sites).

Environmental Protection:

For outdoor or washdown environments, the actuator housing must meet specific standards to protect the internal electronics:

- NEMA 4/4X: Watertight and corrosion-resistant (Standard for Oil & Gas).

- IP67/IP68: Dust-tight and protection against immersion (Essential for Water/Wastewater operations).

Types and Connections: Choosing the Right Fit

Selecting the correct body style is just as critical as sizing the actuator. If the connection type doesn’t match your piping systems or pressure requirements, you risk leaks or structural failure. In this Electric Butterfly Valve Guide, I break down the physical configurations you need to know to ensure your fluid control systems hold up under pressure.

Concentric vs. Eccentric: When to Upgrade to High-Performance

The internal design of the valve dictates how it handles pressure and friction.

- Concentric (Resilient Seated): This is the standard “zero offset” design found in most general applications. The valve stem passes through the center of the disc or vane and the ring seat. It is perfect for low-pressure water and air, offering a tight seal at a lower cost.

- Eccentric (High-Performance): When dealing with higher pressures or steam, I upgrade to an eccentric design (double or triple offset). The stem is offset from the center, causing the butterfly plate to cam away from the seat immediately upon rotation. This reduces friction, lowers torque requirements, and significantly extends the life of the seal in harsh media.

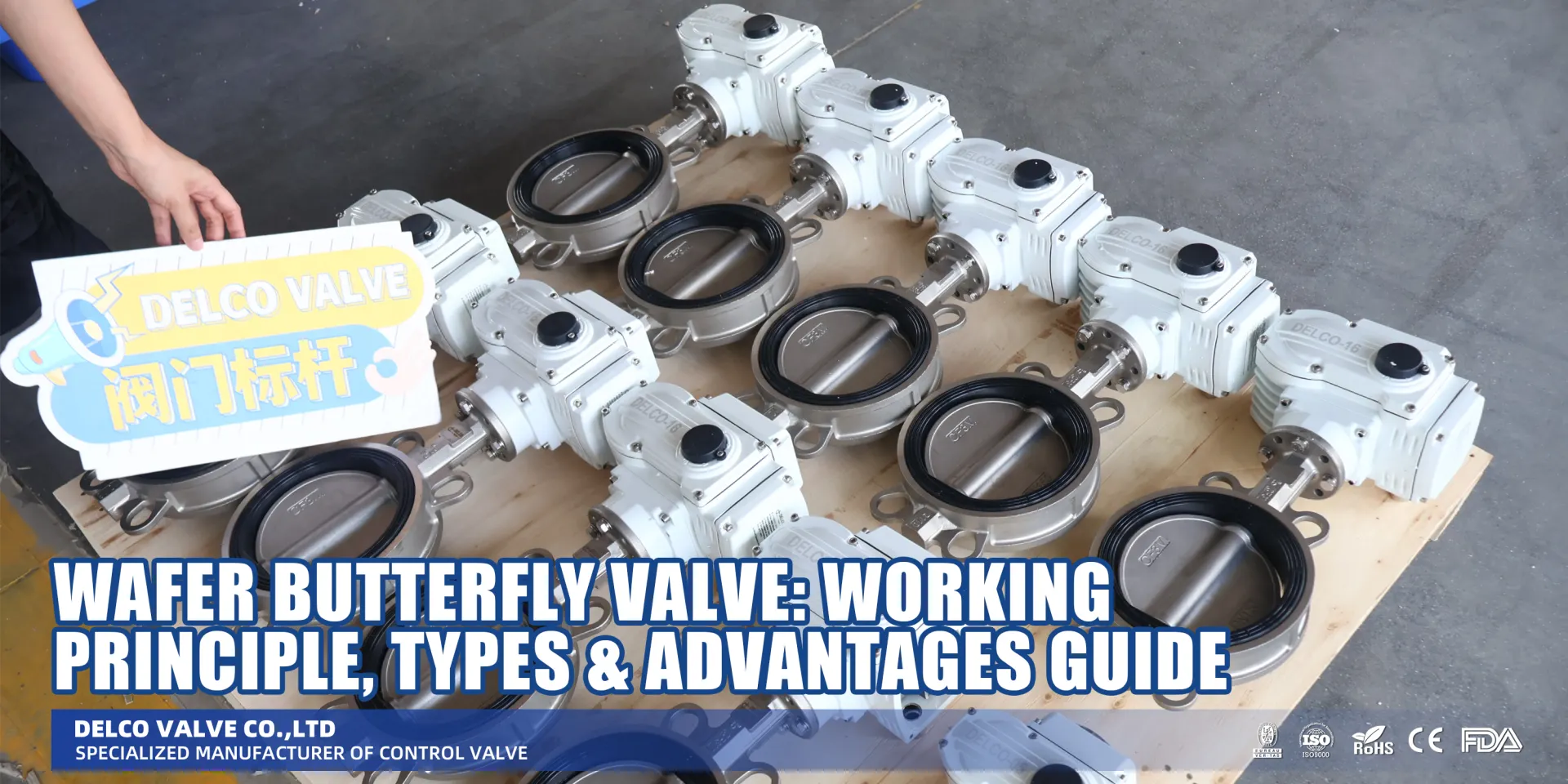

Wafer vs. Lug Style: Why “End-of-Line” Service Matters

The choice between Wafer and Lug often comes down to maintenance needs and installation location within the pipeline.

- Wafer Style: These valves are sandwiched between two pipe flanges using long bolts. They are lightweight and cost-effective. However, they cannot be used as an end-of-line valve; if you remove the downstream piping, the valve falls out.

- Lug Style: These feature threaded inserts on the valve body. I recommend Lug style for industrial valves that may require downstream maintenance. You can bolt the valve to a single flange, allowing it to cap off the line (dead-end service) while maintaining upstream pressure. This is crucial for safe maintenance without draining the entire system.

Flanged Connections for Heavy-Duty Piping Systems

For larger diameters—common in wastewater operations and large-scale cooling loops—standard wafer or lug bodies can be difficult to align. Double flanged electrically actuated valves solve this.

These valve assemblies have flanges built directly into the body that match the pipe flanges. This design provides the highest level of mechanical stability and ensures the ductile iron disc or stainless steel shaft remains perfectly aligned, even under high flow velocities. If you are managing massive fluid flow control infrastructure, the flanged connection is the most robust option to prevent body distortion.

Seat & Disc Materials: Preventing Chemical Failure

Selecting the right Electric Butterfly Valve Guide involves more than just sizing the actuator; you must ensure the internal components can survive the media. If the seat material swells or the disc corrodes, the friction increases, changing the torque requirements. This often causes the electric actuator to stall or burn out. We prioritize matching the chemical compatibility of the valve internals to your specific piping systems to ensure longevity.

The Rubber Debate: EPDM vs. NBR for Water and Oil

For standard resilient seated valves, the ring seat is usually an elastomer. Choosing the wrong rubber is the most common cause of failure in fluid control systems.

- EPDM: This is our standard for water, glycol, and steam applications. It handles temperature fluctuations well but degrades rapidly if exposed to oils or petroleum.

- NBR (Buna-N): This is essential for industrial valves handling hydrocarbons, fuels, and oils.

- The Risk: Using EPDM in an oil line causes the seat to swell. This traps the butterfly plate, spiking the torque needed to turn the valve and potentially damaging the actuator gears.

PTFE/Teflon Seats: Handling Corrosive Chemicals

When liquid and gas applications involve aggressive acids, solvents, or higher temperatures, rubber liners are insufficient. In these cases, we utilize PTFE (Teflon) seats. PTFE offers near-universal chemical resistance and a low coefficient of friction, which helps keep torque output requirements manageable. These are typical in our High Performance double offset valves, providing a tight seal without the risk of chemical degradation found in standard elastomers.

Disc Materials: Ductile Iron vs. Stainless Steel 316

The disc sits directly in the flow stream and endures constant erosion and pressure. We stock various materials to balance cost and performance:

- Ductile Iron Disc: Strong and cost-effective. These are ideal for fresh water, HVAC, and general utility lines. We often supply these with nickel plating to extend service life.

- Stainless Steel (CF8M/316): The industry standard for corrosive environments. A 316 SS disc paired with a stainless steel shaft provides excellent resistance to rust and chemical attack.

- Selection Tip: For wastewater operations or chemical processing, upgrading to Stainless Steel prevents the disc from pitting, ensuring the valve stem and seal remain intact for reliable flow regulation.

Selection Guide: Avoid the “Torque Trap”

Selecting the right Electric Butterfly Valve isn’t just about picking a size; it requires careful calculation of forces to prevent equipment failure. At Delco Valves, we see many systems fail because the actuator type wasn’t strong enough to turn the disc against the line pressure.

Calculating Torque: Why Safety Margins Matter (Dry Media vs. Lubricated)

Last year, we helped a client retrofit a chemical plant who initially sized their actuators without a safety margin. After just two months of handling viscous slurry, three actuators burned out because the torque required to break the seat seal was 15% higher than the motor's rating. This is why we insist on that 30% buffer—it’s cheaper than downtime.

The most common mistake in automation is undersizing the actuator based on nominal torque figures. The actual torque requirements change heavily based on the media flowing through the pipeline.

- Lubricated Media: Clean liquids like water or oil naturally lubricate the ring seat, reducing friction.

- Dry Media: Air, gases, or powders create significant drag on the butterfly plate, requiring higher torque output.

We always recommend applying a safety factor—typically adding 25% to 30% to the valve’s raw torque rating. If you are operating High Performance or Triple Offset valves in critical services, this margin ensures the electric actuator has enough power to break the seal after long periods of inactivity without stalling.

Sizing for Flow Coefficient (Cv) and Pressure Drop

Don’t just match the valve size to the pipe size. You must consider the Flow Coefficient (Cv) to ensure efficient fluid flow control. The Cv value indicates the volume of water (in gallons per minute) that flows through the valve with a 1 PSI pressure drop.

- Undersized Valves: Create excessive pressure drop, noise, and cavitation, damaging the piping systems.

- Oversized Valves: Reduce precise control capabilities, making the valve act like an on/off switch rather than a throttling valve.

We assist in calculating the correct Cv to balance flow capacity with control authority, ensuring your liquid and gas systems operate efficiently.

Matching the Actuator to the Valve (ISO 5211 Mounting)

The physical connection between the valve stem and the actuator gearbox is defined by the ISO 5211 mounting standard. This international standard ensures that valve assemblies are modular and interchangeable.

Our industrial valves feature standardized ISO mounting pads, allowing for direct mounting of electrically actuated units. This eliminates the need for complex brackets or couplers in most cases, reducing hysteresis (lag) and ensuring the rotary motion of the actuator translates instantly to the stem. Whether you are fitting a Resilient Seated unit or a heavy-duty Carbon Steel body, proper mounting alignment prevents stem wear and extends the lifecycle of the entire package.

Common Applications

Our electric butterfly valves are workhorses in fluid control systems across the globe. Whether handling liquid and gas, we supply valve assemblies that are engineered to fit specific industrial needs, from general utility to critical service.

HVAC & Water Treatment

In the HVAC sector, precise flow regulation is key to energy efficiency. Our resilient seated valves are the industry standard for managing chilled or hot water loops within complex piping systems. They offer a tight shutoff and are easy to automate for remote operation.

For wastewater operations, reliability is non-negotiable. We provide automated solutions that handle high-volume water flows without the need for constant manual intervention.

- Water Distribution: Large diameter valves (up to 72″) control main lines.

- Treatment Plants: Electric actuators allow for timed cycles and remote monitoring.

- General Utility: Cost-effective resilient seated options work best here.

Chemical Processing & Slurry Handling

When the media turns aggressive, standard valves won’t cut it. For chemical processing, we deploy High Performance (Double Offset) or Triple Offset valves made from Stainless Steel (CF8M) or specialty alloys to resist corrosion. These industrial valves are designed to meet ASME and API standards, ensuring safety in hazardous environments.

Slurry handling is even tougher; the valve must cut through particulates without jamming. In these setups, the actuator type is critical—it must deliver high torque requirements to ensure a tight seal every time.

- Corrosive Media: PTFE or metal-seated valves prevent chemical attack.

- Viscous Fluids: High-torque electric actuators power through thick liquids.

- Precise Control: Modulating actuators allow for exact throttling in chemical mixing.

Installation and Maintenance

Installation Don’ts: Preventing Liner Distortion

We often see performance issues stem from improper installation rather than product failure. For resilient seated butterfly valves, the rubber liner extends over the body face to act as a built-in seal. Do not use additional flange gaskets. Adding extra gaskets compresses the liner too much, causing the rubber to distort and grip the butterfly plate. This friction spikes the torque requirements, potentially stalling the electric actuator.

To ensure a smooth start-up in your piping systems:

- Align flanges perfectly before tightening bolts.

- Keep the disc or vane slightly open (about 10 degrees) during installation to prevent the edge from jamming against the liner.

- Tighten bolts in a star pattern to apply even pressure across the valve assemblies.

Wiring Best Practices and Limit Switch Adjustment

The electric actuator is the brain of the operation, and incorrect wiring is the fastest way to kill it. Always verify that the supply voltage matches the actuator’s nameplate before connecting power. Running 220V into a 110V unit will destroy the internal components instantly.

Once powered, setting the limit switches is critical for precise control. These switches tell the motor when to stop the valve stem rotation.

- Close Limit: Set this first to ensure the valve seals tight without over-torquing the seat.

- Open Limit: Adjust this to stop the disc exactly at 90 degrees for maximum flow.

- Sealing: Use proper cable glands to seal the conduit entries. Moisture inside the housing is a leading cause of electrical failure in electrically actuated units.

Troubleshooting Actuator Overheating and Seal Leaks

If your actuator is running hot, check the duty cycle. Standard electric actuators are generally not designed for continuous, non-stop modulation. If the valve cycles too frequently, the motor creates excess heat. Overheating can also indicate that the valve is undersized or stuck, demanding more torque output than the actuator can provide.

For leaks, identify the source:

- Through the valve: usually indicates damage to the ring seat or debris trapped in the line.

- At the stem: suggests the stem seals are worn, often due to abrasive media or misalignment.

Regular maintenance and cycling the valve periodically (even if usually static) keeps the fluid control systems responsive and prevents the seat from bonding to the disc.

Frequently Asked Questions (FAQ)

Are butterfly valves better than gate valves for flow control?

In my experience with fluid control systems, the electric butterfly valve is almost always the superior choice for automation compared to gate valves. Gate valves are designed strictly for isolation (fully open or fully closed) and require multiple turns to operate, making them slow and heavy.

A butterfly valve uses quarter-turn rotary motion, meaning it opens and closes in seconds. This makes them much more responsive for active fluid flow control. They are also significantly lighter and more compact, which saves valuable space and reduces stress on your piping systems. If you need frequent operation or automation, the butterfly valve wins every time.

Can electric butterfly valves be used for throttling?

Yes, they serve as effective throttling valves. While they aren’t as surgically precise as globe valves, an electrically actuated butterfly valve paired with a modulating actuator offers excellent flow regulation for most industrial applications.

To get the best performance when throttling:

- Operating Range: Aim to keep the disc opening between 30° and 70° for stable flow.

- Control Signals: Use an actuator that supports 4-20mA signals for precise control.

- Torque: Ensure the torque output of the actuator is sized to handle the dynamic forces of the moving media, not just the static break torque.

How long do electric butterfly valves typically last?

The lifespan varies based on the media passing through the pipeline and the cycle frequency. The rigid components, like the ductile iron disc and stainless steel shaft, are incredibly durable and rarely fail. Usually, the soft parts—specifically the ring seat—are the first to degrade due to friction or chemical attack.

In standard water or HVAC applications, these valve assemblies can easily last over 10 years. In harsh wastewater operations or abrasive slurries, the seat may need replacement sooner. Proper maintenance, such as checking for seal wear and ensuring the actuator isn’t overheating, is the best way to maximize service life.

About the Author: The DELCO Valve Engineering Team

With over 20 years of expertise in industrial flow control, DELCO Valves specializes in engineering high-performance actuation solutions for the Oil & Gas, Chemical, and Water Treatment sectors. We don’t just supply hardware; we deliver turn-key automation packages tested to rigorous API and ISO standards.

Ready to Automate Your Piping System? Don't let sizing errors compromise your project. At Delco Valves, our engineering team is ready to help you calculate the exact torque requirements and select the perfect electric butterfly valve for your application.

👉 Contact Us Today for a free consultation and quote.