Home /

Home / Four-Way Valve: Operating Principles and Industrial Applications

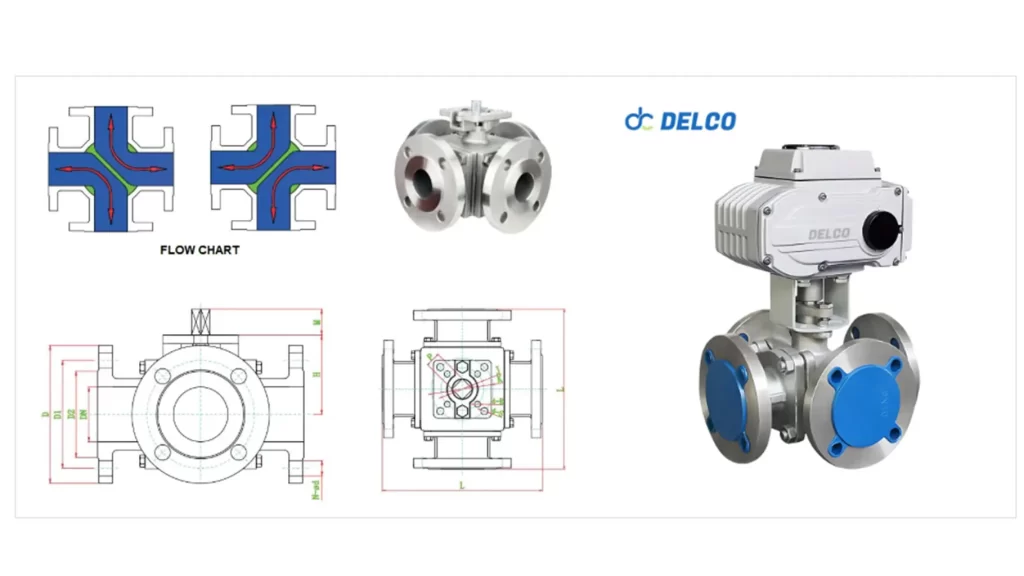

DELCO Valve provides a wide range of industrial valve solutions, specializing in control valves and four-way motorized ball valves designed for reliable fluid control in hydraulic and pneumatic systems.

What Is a Four-Way Valve?

A four-way valve is a directional control valve used to manage and redirect fluid flow within various systems.

It is typically a spool-type valve with equal surface areas for both the pump and the reservoir.

Due to its symmetrical design, it allows precise control of fluid direction, making it ideal for industrial automation and actuator applications.

Structure of a Four-Way Valve

A standard four-way valve consists of:

- A valve chamber with four ports.

- A valve spool containing two “L-shaped” channels that connect adjacent ports.

- A spool shape that can be cylindrical, conical, or spherical.

When positioned at the center, the spool maintains open flow paths between the inlet and outlet ports, enabling efficient and balanced operation.

Example: DELCO’s 4 Way Flange Motorized Ball Valve is designed with precision sealing and compact structure for long-term industrial reliability.

Working Principle of a Four-Way Valve

The four-way valve operates using two disconnected L-shaped channels to control the fluid path.

Originally used in double-acting steam engines, it now plays a crucial role in hydraulic actuators and pneumatic systems.

When activated, the valve directs pressure to one side of the cylinder while releasing pressure from the other side.

This alternating flow allows actuators to extend and retract smoothly — ensuring accurate directional control without signal loss.

Applications of Four-Way Valves

Four-way valves are essential in systems that require bi-directional flow or multi-path fluid control, including:

- Hydraulic and pneumatic automation lines

- Double-acting cylinders

- Industrial actuator systems

- Motorized valve assemblies

These valves are a core part of industrial fluid control engineering, helping operators maintain system efficiency and stability.

Advantages of Four-Way Valves

Versatility: Provide multiple flow paths, adaptable to various system requirements.

Precise Control: Enable accurate fluid management for actuators and cylinders.

Compact Design: Integrate multiple functions into a single component, reducing cost and installation complexity.

System Efficiency: Maintain balanced flow to minimize energy loss in hydraulic and pneumatic systems.

Disadvantages of Four-Way Valves

Higher Complexity: Require careful design to ensure reliability and precision.

Cost Consideration: Typically more expensive than three-way valves due to additional components and automation features.

Maintenance Requirements: Internal structure can be more complex, requiring skilled maintenance to prevent leakage or wear.

Difference Between Three-Way and Four-Way Valves

| Feature | Three-Way Valve | Four-Way Valve |

|---|---|---|

| Number of Ports | 3 (1 inlet, 2 outlets or vice versa) | 4 (2 inlets and 2 outlets) |

| Function | Mixing or diverting flow | Directional control for actuators |

| Application | Simple flow redirection | Complex hydraulic/pneumatic systems |

| Example | Temperature or flow regulation | Double-acting cylinder control |

In short, a three-way valve handles simple flow switching, while a four-way valve enables full directional control in industrial systems.

Conclusion

Four-way valves are critical components in industrial automation, providing unmatched versatility, precision, and flow management.

Despite their complexity and cost, they deliver long-term benefits through improved control and system efficiency.

For professional-grade control valve solutions, including 4 way motorized ball valves and hydraulic directional valves,

contact DELCO Valve — your trusted partner in industrial valve engineering.