Home /

Home / Manual Globe Valve: Design, Functions, Types & Essential Maintenance Guide

DELCO Valve: We offer a full range of high-quality industrial valves, including specialized solutions for flow control.

What is a Manual Globe Valve?

A manual globe valve is a critical type of linear motion valve engineered for precise regulation of fluid flow in industrial piping systems. Its defining feature is a spherical body and a movable disc that operates perpendicular to the flow path—hence the name "globe."

By simply rotating the handwheel, operators can finely adjust the flow rate to the required level. Due to its superior flow control capabilities and robust, easy-to-maintain design, the globe valve is indispensable across a spectrum of demanding industrial applications, including water treatment, oil and gas, chemical processing, and power generation.

This comprehensive guide will detail the design, core functions, primary types, key advantages, and essential maintenance practices of manual globe valves.

Understanding the Core Structure of a Globe Valve

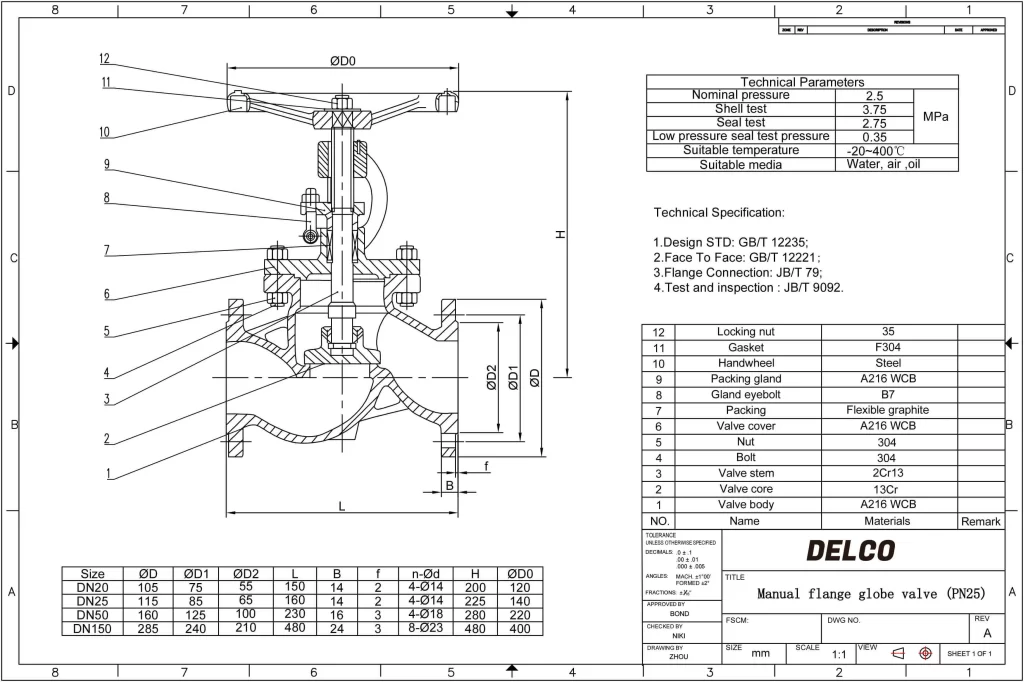

A manual globe valve is structurally composed of several robust components working in concert to manage flow. The key parts include the valve body, bonnet, stem, disc, seat, and handwheel/actuator:

Handwheel or Actuator: The mechanism used to operate the valve, providing manual rotation (handwheel) or automatic control (actuator).

Valve Body: The main pressure-containing boundary, connecting directly to the pipeline. Common construction materials for industrial globe valves include stainless steel, cast iron, carbon steel, and various alloy materials, selected based on pressure and fluid compatibility.

Bonnet: A cover bolted or threaded to the valve body, providing a crucial seal for the valve's internal components.

Stem: The threaded shaft connecting the handwheel to the disc. Its vertical movement, controlled by the handwheel rotation, is what positions the disc.

Disc (or Plug): The movable throttling or shut-off element. Its design directly impacts the valve's flow control characteristics.

Seat: The fixed sealing surface against which the disc is pressed to stop or regulate flow. The disc/seat geometry is essential for the precise flow control capability of globe valves.

Handwheel or Actuator: The mechanism used to operate the valve, providing manual rotation (handwheel) or automatic control (actuator).

The Three Main Types of Globe Valves and Their Applications

Globe valves are classified primarily by their body design, which influences flow path and pressure drop. The three major types are:

Application: Perfect for applications that require a change in flow direction while simultaneously saving space and reducing the need for additional pipe fittings.

1.Z-Type Globe Valve (Straight-Through):

Design: The most conventional type, characterized by a Z-shaped internal flow path. The horizontal seat allows the stem and disc to move perpendicular to the flow direction.

Application: Provides a simplified flow path compared to older designs, making it suitable for general service where flow resistance is acceptable.

2.Y-Type Globe Valve:

Design: Features a Y-shaped body where the stem and seat are angled (typically $45^{\circ}$) relative to the flow.

Application: This angular design significantly reduces flow resistance and minimizes pressure drop, making the Y-type globe valve ideal for systems requiring high flow rates and applications involving slurry or erosive fluids.

3.Angle Globe Valve:

Design: The inlet and outlet are positioned at a $90^{\circ}$ angle, effectively combining the function of a valve and a pipe elbow.

Application: Perfect for applications that require a change in flow direction while simultaneously saving space and reducing the need for additional pipe fittings.

Core Functions: Why Choose a Globe Valve for Flow Control?

The manual globe valve is primarily valued for its outstanding capability in flow management:

Emergency & Backflow Prevention: Can be rapidly closed during emergencies for system safety, and when properly installed, prevents unwanted fluid backflow during system shutdown.

Precise Throttling and Regulation (Key Function): By adjusting the handwheel, the operator precisely controls the disc's position, allowing the valve to operate effectively across the full range from fully closed to fully open, and critically, at any intermediate point for accurate flow modulation.

Reliable Shutoff (On-Off Control): When the disc is fully seated, the vertical movement ensures a tight, positive seal, making it an excellent shutoff valve.

System Pressure Regulation: Partial closure introduces variable resistance, which can be used strategically to regulate or reduce downstream pressure.

Emergency & Backflow Prevention: Can be rapidly closed during emergencies for system safety, and when properly installed, prevents unwanted fluid backflow during system shutdown.

Advantages of Manual Globe Valves in Industrial Settings

The globe valve remains a preferred choice due to its robust benefits:

Ease of Maintenance: Simple, straightforward design permits easy in-line disassembly and maintenance (bonnet removal), significantly reducing downtime and operating costs.

Exceptional Flow Regulation: Its design excels where fine, continuous adjustments (throttling) are necessary.

Superior Sealing Integrity: The linear motion and perpendicular seating mechanism ensure a reliably tight, low-leakage seal.

Durability and Resilience: Constructed from materials capable of withstanding high temperatures, high pressures, and corrosive media, ensuring a long service life.

High Versatility: Available in numerous materials, sizes, and connection types to meet nearly any process requirement.

Ease of Maintenance: Simple, straightforward design permits easy in-line disassembly and maintenance (bonnet removal), significantly reducing downtime and operating costs.

Essential Maintenance Practices for Globe Valve Longevity

Proper maintenance is paramount for ensuring the long-term reliability and performance of your manual globe valves:

Installation Verification: Ensure correct alignment and secure mounting, as improper installation can induce stress leading to premature wear on internal components.

Routine Visual Inspection: Establish a schedule to check for early signs of stem leakage, external corrosion, and wear on the body or bonnet.

Lubrication Schedule: Keep the valve stem and gland packing lubricated according to manufacturer specifications to ensure smooth operation and prevent stem seizure or sticking.

Cleaning: Remove any external debris or internal buildup that could affect disc movement or sealing effectiveness.

Timely Part Replacement: Replace worn components (especially the disc, seat, and packing) promptly to prevent catastrophic failure or chronic leakage.

Installation Verification: Ensure correct alignment and secure mounting, as improper installation can induce stress leading to premature wear on internal components.

Conclusion

Manual globe valves are foundational components in modern fluid control systems, delivering unmatched precision in flow regulation, dependable shutoff, and rugged durability. Their adaptability, with types like the Z-Type, Y-Type, and Angle valve, makes them suitable for the most demanding industrial environments. By adhering to proper design selection, operation, and the essential maintenance practices detailed above, users can ensure maximum performance and safety from these critical valves.

- PREV: Four-Way Valve: Operating Principles and Industrial Applications

- NEXT: Not NEXT