Home /

Home / Pneumatic Knife Gate Valve: Features, Application Areas, and Selection Guide

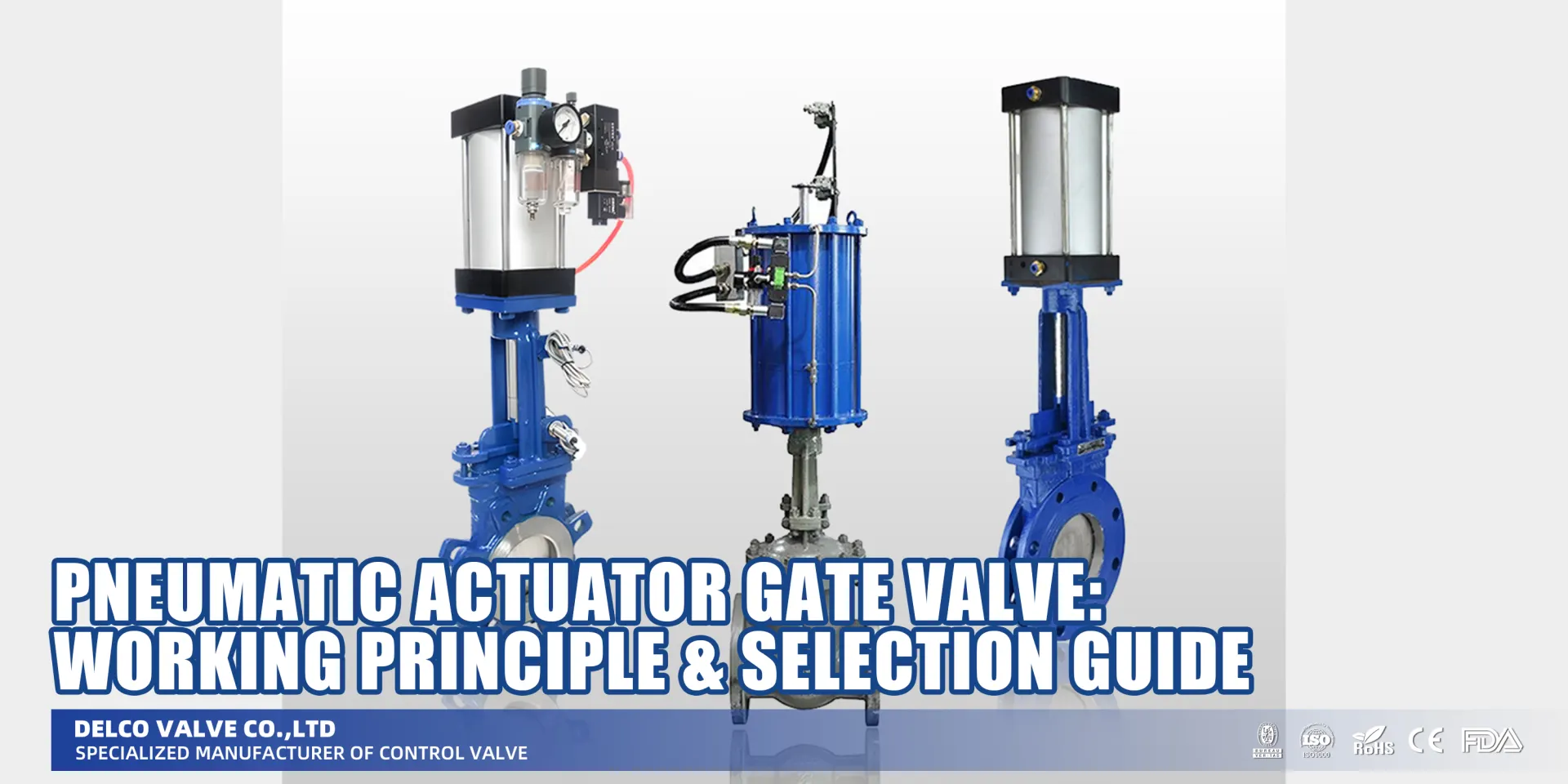

What is a Pneumatic Knife Gate Valve?

At Delco Valve, we often receive inquiries from engineers frustrated by jammed valves. A pneumatic knife gate valve is the solution we recommend when standard valves simply cannot handle the load. Engineered specifically for difficult flow conditions, these heavy-duty units utilize a sharpened blade—the knife edge—to cut through heavy liquids, slurry, and suspended solids. By integrating a pneumatic actuator, the valve automates flow control, utilizing compressed air to drive the gate, ensuring rapid and powerful actuation in harsh environments like mining and wastewater treatment.

Definition and Basic Working Principle

The core function of this valve relies on a linear motion mechanism. When air pressure is applied to the actuator, it drives the gate down to cut through the media and seal against the valve seat, or pulls it up to allow full flow.

- Shearing Action: The beveled gate effectively slices through viscous fluids, wood pulp, and sludge, preventing the wedge effect that causes jamming in other valve types.

- On-Off Operation: Designed primarily for isolation, these valves provide a tight shut-off even when solid particles are present in the industrial pipeline.

- Debris-clearing behavior: During travel, the gate can help push buildup away from the seating area. Performance depends on media, seat design, and cycling frequency.

Key Components Breakdown

To ensure durability and reliable sealing, our pneumatic knife gate valves are constructed from high-grade materials tailored to specific technical parameters.

- Valve Body: Available in robust materials including Ductile Iron, Cast Carbon Steel (WCB), and Stainless Steel (CF8, CF8M) to withstand internal pressures up to ANSI 150LB or PN16.

- Pneumatic Actuator: The power source, typically a double-acting or spring-return cylinder, that converts air pressure into linear force.

- Gate (Knife): A precision-machined stainless steel plate designed to penetrate bulk materials without bending.

- Valve Seat: Critical for leak prevention. Options range from resilient seats (EPDM, NBR, PTFE) for zero leakage to metal-to-metal seats for high-temperature or abrasive applications.

Pneumatic vs. Manual: Why Automate?

While manual valves are functional, upgrading to a pneumatic actuator offers significant operational advantages for modern system design.

- Speed and Efficiency: Pneumatic cylinders cycle much faster than manual handwheels, crucial for emergency shutdowns or high-frequency cycling.

- Remote Control: Automation allows operators to control valves in hazardous or inaccessible locations from a central control room.

- Consistent thrust: Pneumatic actuators deliver repeatable closing force. When correctly sized and paired with the right seat design, this improves isolation reliability compared with manual operation.

- Safety: Reduces physical strain on operators and minimizes exposure to dangerous environments.

Key Features and Advantages

When selecting valves for automated industrial systems, understanding the core benefits of a pneumatic knife gate valve is essential for optimizing system design. We engineer these valves to solve specific flow control challenges that standard gate or globe valves simply cannot handle.

Superior Cutting Performance for Difficult Media

The primary strength of this valve lies in its ability to handle slurry, viscous fluids, and pulp without clogging. Unlike traditional valves that rely on a wedge, our design utilizes a sharp knife edge gate. Driven by a powerful pneumatic actuator, the gate acts like a guillotine, slicing directly through suspended solids and heavy fibers. This shearing action ensures the valve closes fully every time, preventing media buildup in the valve body that could lead to operational failure.

Compact Structure and Space Efficiency

Space is often a luxury in complex industrial pipeline layouts. These valves feature a compact structure with a very short face-to-face dimension, typically known as a wafer design.

- Light-weight material: Constructed from robust yet lighter materials like Ductile Iron or Stainless Steel, they reduce the physical load on the piping system.

- Easy Installation: The slim profile allows for installation in tight spaces where bulky valves would not fit.

- Cost-Effective: Less material and smaller actuators translate to lower initial costs and easier maintenance.

Reliable Sealing and Flow Transfer

We prioritize reliable sealing to ensure safety and efficiency. The precision-machined gate maintains tight contact with the valve seat, available in soft (EPDM, PTFE) or metal options to suit your temperature and abrasion requirements. This design minimizes pressure drop and ensures efficient flow transfer when the valve is open.

Feature vs. Benefit Breakdown:

| Feature | Technical Advantage | Operational Benefit |

|---|---|---|

| Beveled Knife Edge | Cuts through solids and fibers | Prevents jamming in wastewater or mining applications. |

| Full Port Design | Eliminates flow restrictions | Maximizes flow capacity and reduces energy loss. |

| Pneumatic Actuation | Fast, automated cycling | Increases process speed and allows remote control. |

| Zero Leakage Seat | Tight shut-off capabilities | Prevents product loss and maintains a clean environment. |

Quick selection rules (field-proven):

- If your line has abrasive slurry/high solids or high velocity, prioritize metal seat (and consider protective features).

- If you need end-of-line isolation or frequent downstream maintenance, choose lug type.

- If pressure can reverse (backwash/pump changeover), consider bi-directional designs.

By integrating high-quality components from Delco Valves, operators gain a solution that balances durability with precision control.

Common Types of Pneumatic Knife Gate Valves

When designing an industrial pipeline, selecting the right valve configuration is just as critical as the actuator itself. We offer distinct structural designs tailored to specific pressure ratings, installation constraints, and maintenance requirements. Understanding these variations ensures your system design remains efficient and safe.

Wafer, Lug, and Flanged Type Connections

The connection style dictates how the valve integrates into your piping system.

Wafer Type: This is generally the more economical and light-weight material option. The valve body is sandwiched between two pipe flanges. It is ideal for systems where space is at a premium and connecting dimensions need to be compact.

Lug Type: These valves feature threaded inserts around the body. This design allows for more secure bolting and enables dead-end service (end-of-line installation). If you need to remove downstream piping while keeping the upstream pressure contained, the lug type is the necessary choice.

Flanged Type: Features full flanges on both sides (often U-type body). This robust design is preferred for larger diameters or applications requiring standard face-to-face dimensions compatible with traditional gate valves.

Both styles are manufactured to meet standard flange ratings, such as ANSI 150LB or PN10/16, ensuring compatibility with global infrastructure.

Sealing Designs: Metal vs. Resilient Seated

The valve seat determines the tightness of the shut-off and the valve’s longevity against specific media.

- Resilient Seated (Soft Seat): We use materials like EPDM, NBR, or PTFE to achieve reliable sealing with zero leakage. This is best for water, chemicals, and applications requiring a bubble-tight shut-off.

- Metal Seated: For heavy-duty slurry and viscous fluids containing abrasive rocks or sands, a soft seat would wear out too quickly. Our metal-to-metal seats withstand high temperatures and severe abrasion, prioritizing durability over absolute zero leakage.

Unidirectional vs. Bi-directional Models

Flow directionality is a major factor in flow control stability.

- Unidirectional: These valves are designed to seal primarily in one direction. The line pressure pushes the gate against the seat to create a seal. They are cost-effective and highly efficient for standard on-off operation where the pressure direction is constant.

- Bi-directional: These models can handle flow and pressure from either side. They are essential in complex piping networks where backflow is possible or where the valve must isolate flow regardless of the direction. This versatility prevents leakage issues during system surges or reverse pumping.

Major Industrial Application Areas (Use Cases)

We design our pneumatic knife gate valves to handle the toughest jobs where standard valves simply fail. If your pipeline deals with solids, thick liquids, or abrasive materials, a standard globe or butterfly valve will likely clog. Our valves are engineered specifically to cut through these difficult media, ensuring reliable operation across several critical industries.

Mining and Minerals Processing

This is one of the most demanding environments for any valve. In mining operations, pipelines constantly transport heavy slurry, tailings, and mineral concentrates.

Real-World Case (Chile – Copper Concentrator Slurry Line): A client in Chile operating a copper concentrator slurry line (DN200, PN16) experienced repeated shutdowns when solids packed into the bottom cavity of conventional wedge gate valves. We upgraded the line to a Delco pneumatic knife gate valve with a hardened metal seat, sized for the available air supply and closing thrust. After the change, the customer reported a significant reduction in jamming-related stoppages and reliable isolation even during short-term high-solids surges.

💡 Selection Focus: Metal seat for abrasion resistance + actuator thrust margin for high-solids conditions.

- Abrasive Resistance: We supplied valves with hardened metal seats built to withstand the erosion caused by sharp rocks and grit.

- Cutting Power: The sharp knife edge successfully sliced through the suspended solids, ensuring the valve closed fully every time without jamming.

- Reliability: We ensure tight shut-off in coal washing and mineral separation lines, preventing costly leakage.

Pulp and Paper Industry

The knife gate valve was originally developed for this exact sector. Handling wood pulp and fiber suspensions requires a valve that can cut through the flow rather than blocking it.

Real-World Case (Vietnam – Recycled Paper Mill, Pulper Discharge): A recycled paper mill in Vietnam faced frequent jamming on their pulper discharge valves (DN300) due to mixed contaminants such as plastic tape, fibers, and metal staples. Standard valves could not maintain stable isolation. We replaced them with Delco pneumatic knife gate valves configured with a deflector cone and a precision beveled gate edge. The mill reported drastically longer run times between unplanned shutdowns after the retrofit.

💡 Selection Focus: Debris deflection (via cone) + preventing fiber/staple packing at the seat interface.

- Handling Fiber: The gate cuts through paper stock and recycled fiber that would otherwise build up in a standard valve seat.

- Viscous Fluids: Our pneumatic actuators provide the necessary force to manage thick, viscous fluids and high-density stock.

- Efficiency: Automated operation helps maintain the speed of paper production lines, reducing downtime caused by clogging.

Wastewater Treatment Systems

In wastewater treatment plants, managing sludge and debris is a daily challenge. We supply valves that keep these systems running smoothly.

- Sludge Handling: Ideal for raw sewage, thickened sludge, and scum lines where solids are present.

- Self-Cleaning: The shearing action of the gate pushes debris out of the seating area during closing.

- Corrosion Protection: We use durable materials to resist the corrosive nature of municipal and industrial waste.

Chemical and Food Processing

Precision and material purity are key in these sectors. Our valves are versatile enough to handle both corrosive liquids and dry bulk goods.

- Bulk Materials: Excellent for handling dry powders, pellets, and grains in silos and hoppers. The design prevents material from getting trapped in cavities.

- Chemical Compatibility: We offer stainless steel bodies (like CF8M) to handle aggressive fluids in chemical processing.

- Hygiene: The streamlined flow path minimizes dead zones, reducing the risk of cross-contamination in food production lines.

Engineering Guide: Selection and Technical Parameters

Selecting the right pneumatic knife gate valve requires a deep look into your system’s specific demands. We don’t just pick a size off a shelf; we engineer a solution that withstands your operating environment. Below is a breakdown of how we evaluate the core requirements for a successful installation.

Evaluating Critical Technical Parameters

The first step in our engineering guide is matching the valve specifications to the media flowing through your industrial pipeline. If you are handling slurry, viscous fluids, or suspended solids, standard valves will fail. We need to analyze the chemical composition and temperature to select the right valve body and valve seat materials.

For general water or mild industrial applications, a light-weight material like Ductile Iron or Carbon Steel (WCB) is cost-effective. However, for corrosive environments or food processing, we strictly use Stainless Steel (CF8, CF8M, CF3M).

Key Technical Parameters Checklist:

| Parameter | Options / Standards | Application Note |

|---|---|---|

| Body Material | Ductile Iron, WCB, Stainless Steel | Choose Stainless for corrosion resistance. |

| Seat Material | EPDM, NBR, Viton, PTFE, Metal | Metal seats are best for abrasive bulk materials. |

| Pressure Rating | PN10, PN16, ANSI 150LB | Ensure the valve handles the max line pressure. |

| Temperature | -20°C to +400°C (depending on seat) | High temps require Metal or PTFE seats. |

⚠️ Engineer's Note on Seat Selection: A common mistake we see is using resilient seats (like EPDM) in high-velocity slurry applications to save costs. Don't do this. The abrasive particles will tear the soft rubber within weeks. For mining slurry or pulp with staples/wires, we strongly recommend choosing a Metal-to-Metal seat or a specialized Deflector Cone to protect the seal.

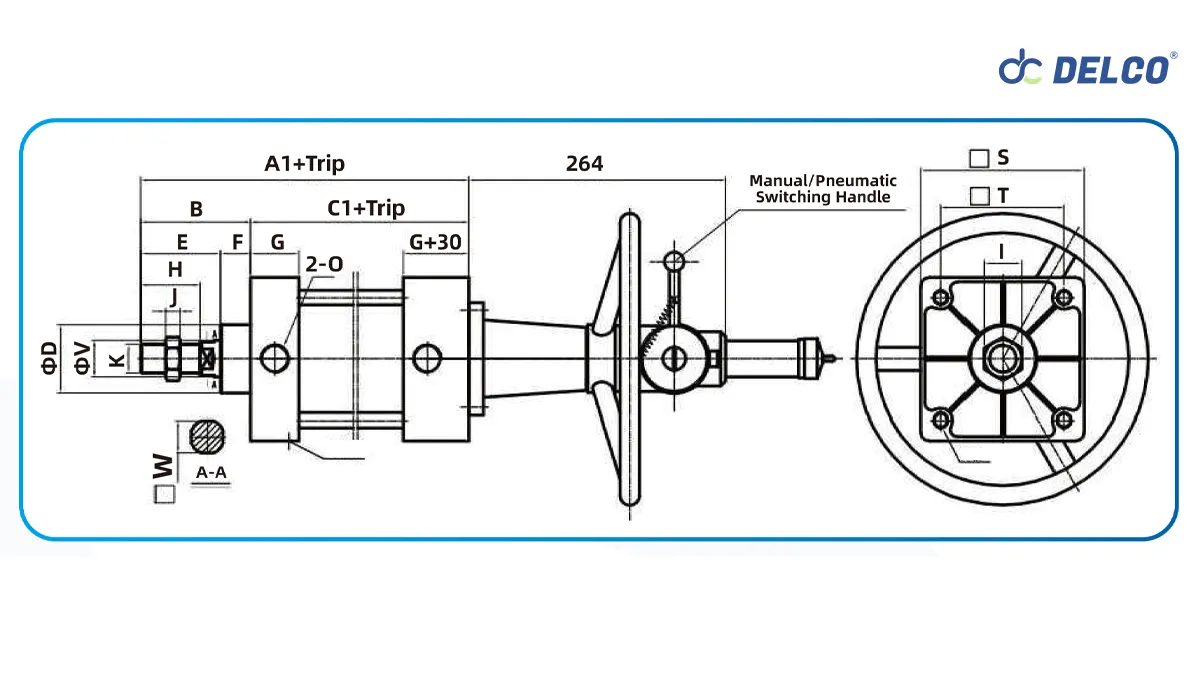

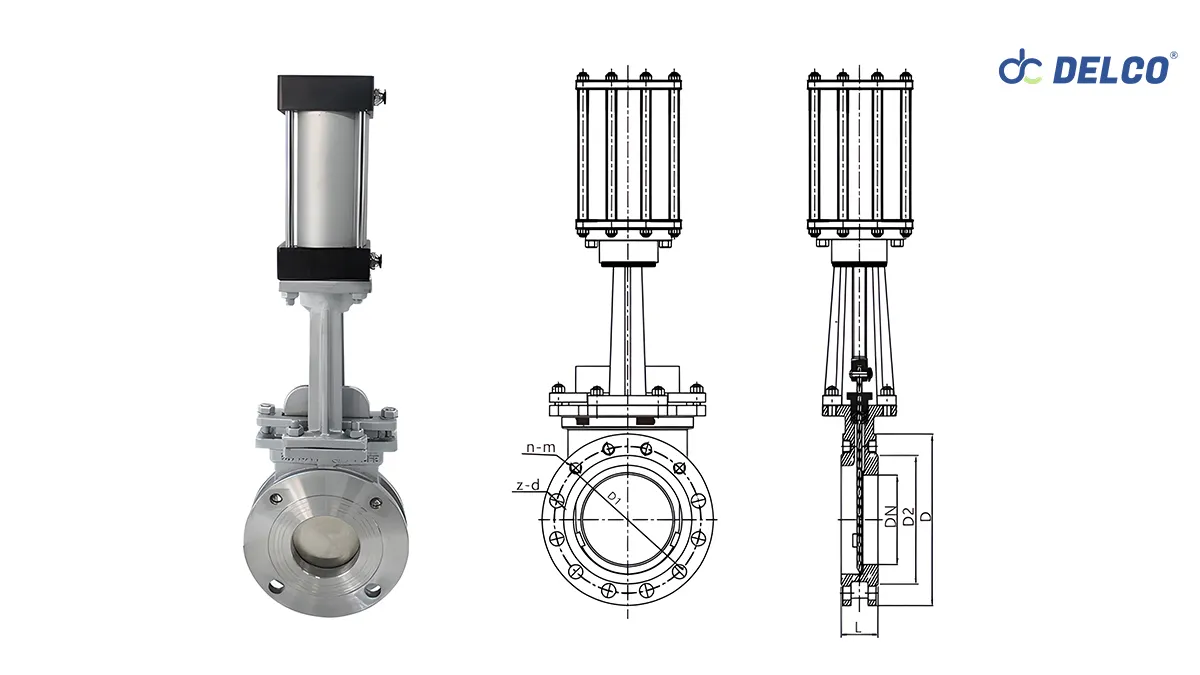

Checking Connecting Dimensions

A valve is useless if it doesn’t fit the pipe. We must verify the connecting dimensions to ensure seamless integration into your system design. This involves checking the flange drilling standards (DIN, ANSI, JIS, or BS) to match your existing piping.

Whether you are using a wafer type or lug type, the face-to-face dimension is critical, especially when replacing an old valve in a tight space. We ensure the bolt circle diameter and the number of bolt holes align perfectly to prevent installation headaches. Accurate dimensional data prevents costly downtime during site fit-up.

Matching Actuator to Process Needs

The pneumatic actuator is the muscle behind the operation. We size the cylinder based on the available air supply pressure and the thrust required to cut through the media. For heavy pulp or thick sludge, we need a larger cylinder to drive the knife edge through the flow without stalling.

We also need to define the control logic. Most applications require simple on-off operation, but some systems need precise flow control.

- Double-Acting: Uses air to open and air to close. Standard for most applications.

- Spring-Return: Fails to a safe position (open or closed) if air supply is lost.

- Accessories: We often add solenoid valves for remote control and limit switches to send position feedback to your control room.

By aligning the actuator power with your process needs, we guarantee reliable, automated performance.

Installation Position and Maintenance Best Practices

Proper setup and care are non-negotiable if you want your pneumatic knife gate valve to last. We design these valves for heavy-duty work, but even the toughest equipment needs the right environment to perform. Ignoring installation guidelines or skipping maintenance schedules is the fastest way to cause leaks, jams, or actuator failure.

Correct Installation Position and Alignment

Getting the installation position right is the first step in successful system design. While our valves are versatile, gravity and physics still apply, especially with a heavy pneumatic actuator attached.

- Vertical Installation is Best: We strongly recommend installing the valve with the stem pointing upward and the actuator on top. This keeps the gate aligned and prevents heavy solids from settling in the valve body cavity.

- Support for Horizontal Lines: If you must install the valve horizontally, you need to support the actuator. Without support, the weight of the pneumatic cylinder creates leverage that can warp the stem or damage the packing seal.

- Check Pressure Direction (Critical): This is the #1 cause of leakage we see in the field. For unidirectional models, the valve relies on line pressure to push the gate against the seat. You must install the valve so the arrow on the body points in the direction of the flow. If installed backward, the abrasive media will blast directly into the sealing face, causing rapid failure.

- Flange Alignment: Ensure your pipeline flanges are parallel and centered before bolting the valve in. Forcing the valve into a misaligned gap puts stress on the casting and can crack the body.

Routine Maintenance for Longevity

Maintenance for a pneumatic knife gate valve is straightforward, but it must be consistent. In harsh environments like mining or wastewater, a little attention goes a long way.

Follow this checklist to ensure operational reliability:

- Lubricate the Stem: Keep the threaded stem well-greased. This reduces friction and strain on the actuator.

- Inspect the Packing: If you see minor weeping around the gate, tighten the packing gland bolts slightly. Do not overtighten, or the gate will bind.

- Check Air Supply: Ensure the pneumatic actuator is receiving clean, dry air at the correct pressure. Moisture in the air lines can corrode the cylinder internals.

- Cycle the Valve: If the valve stays in one position (open or closed) for weeks at a time, cycle it occasionally. This prevents the gate from getting stuck due to dried slurry or scale buildup.

Frequently Asked Questions

What is the difference between a gate valve and a knife gate valve?

The main difference lies in the design of the closure element and the intended media. A standard gate valve typically uses a wedge and is best suited for clean liquids; solids can easily get trapped in the bottom seating area, preventing full closure. In contrast, our knife gate valves feature a sharpened knife edge specifically engineered to slice through suspended solids, slurry, pulp, and viscous fluids. Additionally, the knife gate design offers a much more compact structure and uses light-weight material, making it easier to fit into tight industrial pipeline spaces compared to bulky ANSI gate valves.

Can pneumatic knife gate valves be used for throttling?

While physically possible, we strongly recommend using these valves primarily for on-off operation. Using a standard knife gate valve for partial flow control (throttling) creates high-velocity flow across the gate, which can rapidly erode the valve seat and the gate itself. This premature wear compromises reliable sealing. For most system design applications involving bulk materials or wastewater, the valve should be either fully open to allow unrestricted flow transfer or fully closed to isolate the line.

How do I determine the correct pressure direction for installation?

Correct installation position is vital, especially for unidirectional models. On a unidirectional wafer type valve, the pressure must push the gate against the seat to create a seal. You will typically find a flow or pressure arrow cast or stamped onto the valve body. Always align this arrow with the system’s pressure direction. Installing the valve backward can lead to leakage and may damage the pneumatic actuator or key components when the valve cycles against full line pressure.

About the Author

Delco Valve Engineering Team Specialists in Industrial Flow Control & Valve Export

With over a decade of experience in the valve industry, the Delco Valve team helps international clients navigate complex system designs for mining, paper, and wastewater sectors. We don't just sell valves; we provide the engineering guide you need to keep your pipelines running smoothly.

Have a technical question? Contact us directly or email us at inquiry@delcofluid.com.

- PREV: Pneumatic Actuator Valves: The Ultimate Guide to Selection and Use (2026)

- NEXT: Not NEXT