Home /

Home / Pneumatic vs. Electric Actuated Valves: Which is Best? [Selection Guide]

Confused between Pneumatic and Electric actuators? We compare torque, failsafe options, and maintenance costs in this expert guide to help you choose the right valve.

Understanding Actuated Valves: The Core Conflict

At Delco Valves, we recognize that the efficiency of your piping system hinges on the reliability of its automation. Our Valve Automation Center specializes in converting standard manual valves into sophisticated automated units, but the first critical decision lies in the power source. The conflict between pneumatic and electric actuation is not just about preference; it is a technical calculation involving infrastructure, required torque, and response speed. Whether for the Oil & Gas sector or Power Generation, choosing the correct driving force ensures long-term operational stability and adherence to API and ISO standards.

How Pneumatic Actuators Work (The Muscle of Compressed Air)

Pneumatic actuators are the workhorses of the industry, utilizing a clean dry air supply to generate mechanical motion. By converting fluid pressure into linear or rotary force via a piston or diaphragm, these devices deliver an exceptional power-to-weight ratio.

- Simple Mechanics: Few moving parts reduce wear and maintenance requirements.

- High Output: Capable of generating massive output torque for large-diameter ball valves and butterfly valves.

- Safety: The absence of electrical components in the primary drive makes them ideal for hazardous environments.

How Electric Actuators Work (The Precision of Motors & Gears)

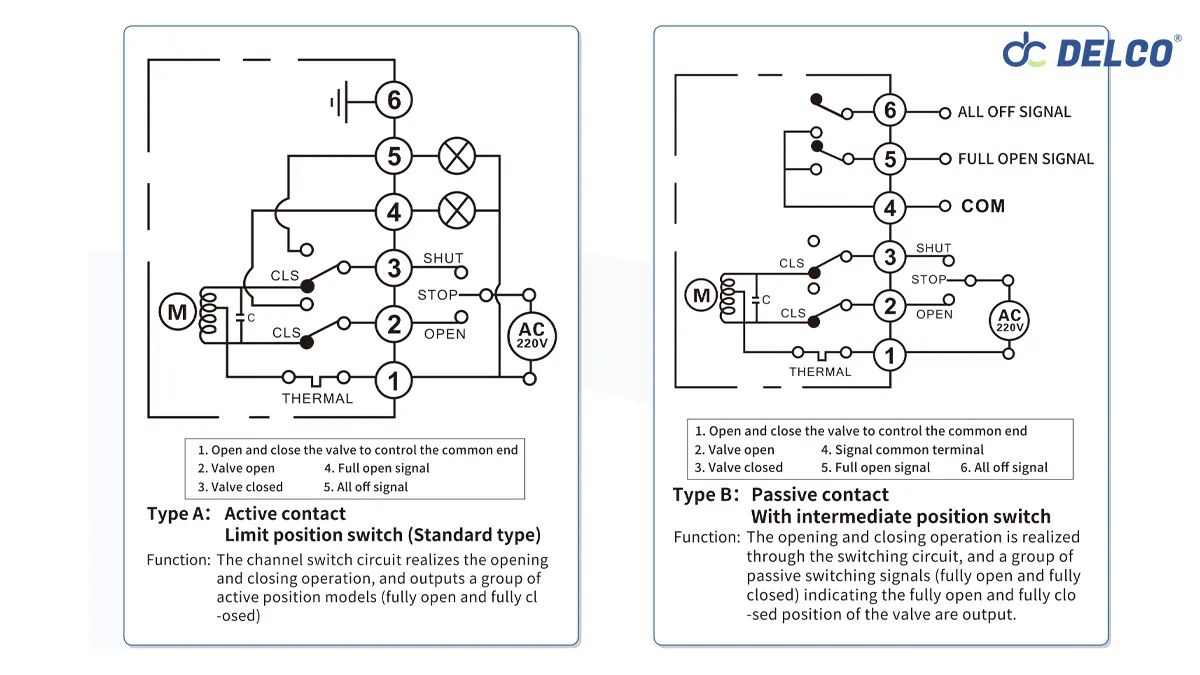

Electric actuators replace air lines with electrical wiring, using a motor and gear train to drive the valve stem. This method provides precise control over position, making them superior for applications requiring exact flow modulation rather than simple on/off duties.

- Accuracy: Gears allow for fine-tuned positioning and modulating control.

- Infrastructure: Eliminates the need for air compressors and piping; requires only a power grid.

- Feedback: Easily integrates into complex automation systems for real-time status monitoring.

The Hybrid Reality: Electro-Pneumatic Systems

Modern industrial applications often require a convergence of technologies. We frequently engineer turn-key valve packages that combine the raw strength of pneumatic rotary actuators with electronic intelligence. By adding ancillary equipment such as solenoid valves and a positioner accessory, we bridge the gap. These electro-pneumatic systems allow digital control signals to regulate the air supply, offering the precision of electronics with the mechanical speed and fail-safe reliability of pneumatics.

Pneumatic Actuators: Speed and Simplicity

When I look at heavy industrial applications, pneumatic actuators are often the default choice, and for good reason. They are the workhorses of the valve world. By utilizing air pressure acting on a piston or diaphragm, these devices convert energy into mechanical motion with incredibly simple internal mechanics. If your facility already has a reliable air supply, integrating pneumatic units is usually straightforward and cost-effective. They don’t overcomplicate things—they just work.

The “Spring-Return” Advantage: Intrinsic Failsafe Safety

The single biggest reason I recommend pneumatic systems for critical lines is the spring-return feature. This provides intrinsic failsafe safety without needing complex electronics or backup batteries.

Here is how it works:

- Operation: Compressed air pushes the spring back to operate the valve.

- Failure Mode: If the air supply or power is cut, the mechanical spring immediately forces the valve into a safe position (either fully open or fully closed).

This mechanical reliability is unbeatable for emergency shutdown (ESD) applications. Unlike electric actuators, which require a battery backup or capacitor to move during a power outage, a pneumatic actuator uses stored mechanical energy. It is a passive system that guarantees fail-safe options are always active.

Durability in Hazardous & Explosive Environments (ATEX/Ex-proof)

In sectors like oil and gas or chemical processing, we often deal with hazardous areas where a single spark could be catastrophic. This is where pneumatics truly shine. Because they operate on fluid pressure (air) rather than electricity, they are naturally explosion-proof.

- No Spark Risk: There are no internal electrical components to arc or overheat.

- Simplified Compliance: Meeting ATEX or other safety standards is easier. You don’t need expensive explosion-proof enclosures for motors.

- Ruggedness: They withstand harsh environmental conditions, including extreme heat and vibration, better than sensitive electronics.

Choosing wiring vs. piping in these zones isn’t just about cost; it’s about safety. Running an air line is inherently safer than running high-voltage cables into a volatile zone.

However, if electricity is your only power source in these zones, we supply certified explosion-proof electric actuators to meet strict safety codes.

High Speed and Rapid Response Times

If your process requires a valve to slam shut in a fraction of a second, pneumatic is the only way to go. The reaction time of a pneumatic actuator is significantly faster than an electric motor.

Electric actuators generally rely on gears to build up torque, which slows down the motion profile. In contrast, pneumatic actuators deliver instant linear force or pneumatic rotary motion the moment the solenoid pilot valve opens.

- Instant Action: Compressed air expands rapidly, driving the piston immediately.

- High Duty Cycle: They can handle high-frequency cycling without overheating, provided you feed them clean dry air.

- Torque Density: They offer a high output torque relative to their physical footprint.

For applications requiring immediate flow diversion or stopping, the raw speed and driving force of pneumatics provide the operation efficiency that geared motors simply cannot match.

Electric Actuators: Precision and Connectivity

At Delco Valves, we see the shift toward electric actuated valves when the application demands exactness over raw speed. While our pneumatic packages are built for muscle, our electric automation solutions are designed for the “brain” of your operation. By utilizing a motor and gear train, these units provide a level of control that compressed air simply cannot match, especially in facilities where running air lines is impractical or too costly.

Modulating Control: Precise Positioning and Repeatability

When your system requires more than just “fully open” or “fully closed,” electric actuation is the superior choice. Through our Valve Automation Center, we configure these units for modulating control, allowing the valve to hold a specific position—say, 45% open—with extreme accuracy.

This capability is driven by the mechanical gear train, which eliminates the “drift” often seen in pneumatic systems relying on air compression. For industries requiring strict flow regulation, such as power generation or chemical processing, this precise control ensures high repeatability. We ensure that whether you are automating a 2″ ball valve or a larger gate valve, the output torque and positioning remain consistent every single time.

Advanced Feedback & IIoT Integration (Data logging, diagnostics)

One of the biggest advantages of going electric is the ease of integration into modern control networks. Unlike pneumatic systems that require complex ancillary equipment like I/P converters and solenoid valves to talk to a DCS, electric actuators are natively digital.

- Simplified Infrastructure: You trade complex piping for standard wiring, reducing the footprint of the installation.

- Real-Time Data: These units can provide immediate feedback on valve position, torque load, and alarm status.

- Diagnostics: Smart electric actuators help predict maintenance needs before a failure occurs.

We build these turn-key valve packages to plug directly into your existing automation system, ensuring seamless communication from the field to the control room.

The Duty Cycle Trap: Understanding Thermal Limitations

While electric actuators offer precision, they have a critical limitation: the duty cycle. Unlike pneumatic actuators which can cycle continuously without issue, electric motors generate heat. If an electric actuator is pushed beyond its rated duty cycle (the ratio of on-time to off-time), it faces a high risk of overheating.

We always advise our global clients to carefully evaluate their operation efficiency requirements. If your process demands continuous modulation or rapid-fire cycling, an electric motor may trip its thermal overload protection. In our custom automation process, we calculate the required frequency of operation against the actuator’s specs to prevent premature failure, ensuring you don’t install a standard duty unit in a high-intensity application.

Critical Comparison: Performance Battleground

At Delco Valves, we engineer automation packages daily, and the performance differences between these two technologies are distinct. When we design a turn-key solution, we look strictly at the physics of how the valve needs to move and the environment it operates in. Here is how they stack up in the field.

Torque & Size: Why Pneumatics Win on Torque-to-Weight Ratio

When you are automating large diameter valves—like our 48″ series—space and weight become critical issues. Pneumatic actuators are power-dense. They generate massive output torque relative to their physical size.

- Pneumatic: Delivers high force with a compact footprint. The cylinder size increases linearly with torque needs, but remains manageable.

- Electric: To generate equivalent torque, electric units require large motors and heavy gearboxes. This results in a bulkier, heavier assembly that may require additional structural support on the pipeline.

Motion Profile: Instant Linear Force vs. Geared Rotary Motion

The fundamental driving force dictates the speed. Pneumatic systems utilize compressed air to create immediate pressure on a piston, translating to near-instant movement.

- Reaction Time: Pneumatics are superior for applications requiring fast cycle times.

- Mechanism: Electric actuators rely on rotary actuator gears to build momentum. While this allows for smooth modulation, it lacks the “snap” action required for emergency isolation.

Failsafe Reliability: Mechanical Spring vs. Battery Backup

In our experience supplying the Oil & Gas industry, reliability is non-negotiable. The spring-return mechanism in pneumatic actuators is the gold standard for safety.

- Mechanical Certainty: If the air supply cuts out, a physical spring forces the valve into a safe position (Open or Closed). It is passive and requires no external power.

- Electric Complexity: Fail-safe options for electrics usually involve battery backups or supercapacitors. These are additional components that require monitoring and eventually degrade, introducing a potential point of failure.

Maintenance: Seal Replacement vs. Electronic Board Failure

Long-term maintenance requirements impact your Total Cost of Ownership. We find that mechanical systems are generally easier for plant crews to service on-site.

| Feature | Pneumatic Actuators | Electric Actuators |

|---|---|---|

| Primary Wear Part | O-rings and Seals | Gears, Motors, Circuit Boards |

| Repair Complexity | Low (Simple Seal Kits) | High (Requires Technician/Replacement) |

| Vulnerability | Contaminated Air | Overheating, Moisture, Voltage Spikes |

| Lifespan | High Cycle Life | Limited by Duty Cycle |

Pneumatic actuators are essentially simple mechanical devices; if they leak, you replace the seals. Electric actuators are complex computers sitting on a pipe. If an electronic board fries due to heat or a surge, you are often looking at a full unit replacement rather than a repair.

Cost Analysis: It’s Not Just the Price Tag

When we engineer a turn-key valve package at our Valve Automation Center, we always advise clients to look beyond the initial invoice. While the upfront cost of the hardware is important, the real financial impact comes from how that equipment interacts with your facility’s infrastructure over time. We stock a massive inventory to keep lead times short, but choosing the right actuation method requires balancing your immediate budget against long-term operational reality.

CAPEX (Upfront): Valve Cost vs. Infrastructure (Compressors vs. Cabling)

If you look strictly at the component cost on our shelf, a pneumatic actuator is almost always significantly cheaper than an electric equivalent, especially for larger valves (e.g., 12″ to 48″). However, CAPEX calculations must include the supporting infrastructure.

- Pneumatic Systems: The actuator is cheap, but do you have the air supply? If you need to install new compressors, dryers, and run extensive piping loops, the installation cost skyrockets.

- Electric Systems: The actuator unit has a higher price tag due to the complex motor and gearing. However, the infrastructure cost is often lower because running standard electrical cabling is generally cheaper and easier than installing rigid wiring vs. piping for air.

For a new facility without an existing air loop, electric actuation often wins on installation cost. For a plant with excess air capacity, pneumatic remains the budget-friendly winner.

OPEX (Running): The Cost of Compressed Air Generation vs. Electricity

Operation efficiency is where the hidden costs lie. Compressed air is one of the most expensive utility sources in an industrial plant. It is energy-inefficient to generate; you lose energy to heat during compression, friction in the pipes, and inevitable leaks.

- Pneumatic Efficiency: You are essentially paying for electricity to run a compressor to generate fluid pressure to move a valve. The energy conversion loss is high.

- Electric Efficiency: Electric actuators consume power directly and usually only draw current when the valve is actually moving.

If you have a high-cycle application, the ongoing electricity bill to generate the required clean dry air for pneumatic actuators will be significantly higher than the direct power consumption of electric units.

Total Cost of Ownership (TCO) over 10 Years

We build our automated packages to meet rigorous API and ISO standards because we know durability lowers TCO. Over a decade, the calculation shifts from energy costs to maintenance requirements.

- Pneumatic Maintenance: These are simple mechanical devices. When they fail, it is usually a seal or diaphragm issue. Repair kits are cheap, and your general maintenance crew can fix them easily.

- Electric Maintenance: These are complex electromechanical devices. Failures often involve circuit boards, capacitors, or motors. Repairs are expensive and may require specialized technicians or complete unit replacement.

For hazardous environments or remote lines where maintenance is difficult, the rugged simplicity of a pneumatic system often results in a lower TCO, provided the air supply is kept dry to prevent internal corrosion.

Selection Guide: How to Choose for Your System

At Delco Valves, our Valve Automation Center handles custom requests daily. We don’t just pull parts off a shelf; we engineer a solution that fits your specific pipeline reality. Choosing between pneumatic and electric isn’t about which technology is “better” on paper—it’s about which one survives your specific environment.

Scenario A: When to Choose Pneumatic (High cycles, HazLoc, Failsafe)

If your facility has a reliable air supply, pneumatic actuation is often the default choice for heavy industrial applications, particularly in the Oil & Gas and Petrochemical sectors we serve.

You should choose pneumatic actuators if:

- You Need Speed: For Emergency Shutdown (ESD) applications, nothing beats the reaction time of compressed air. We can configure packages to close large valves in fractions of a second.

- Safety is Critical: In hazardous areas where sparks can cause explosions, pneumatic systems are inherently safer because they don’t rely on electricity.

- Fail-Safe is Required: Using a spring-return design, the valve automatically drives to a safe position (open or closed) if air pressure is lost. This is the most reliable mechanical safety method available.

- High Duty Cycle: If the valve cycles hundreds of times a day, air cylinders won’t overheat like electric motors might.

Scenario B: When to Choose Electric (Remote sites, Precision, No air supply)

Electric actuators are the problem solvers for isolated infrastructure and processes requiring exact flow management. When running air lines is impossible or too expensive, electricity is the answer.

You should choose electric actuators if:

- Infrastructure is Limited: For remote sites or pipelines where installing compressors and piping for air is cost-prohibitive, running a power cable is much cheaper.

- You Need Precision: If your application requires modulating control (throttling a valve to 25%, 50%, or 75% open), electric motors with gears provide superior precise control compared to pneumatic systems.

- Cold Weather Operation: While pneumatic lines can freeze if the air isn’t dry, electric actuators (equipped with heaters) perform reliably in freezing conditions without the risk of ice blocking the lines.

- Silent Operation: Electric systems are significantly quieter than the exhaust noise associated with pneumatic cycling.

For outdoor installations subject to heavy rain, our IP68 water-proof electric actuators ensure zero water ingress.

Checklist: Assessing Your Plant’s Air Quality and Power Grid

Before we finalize your “turn-key” valve package, run through this checklist to ensure your facility can support the automation hardware.

| Factor | Pneumatic Requirements | Electric Requirements |

|---|---|---|

| Power Source | Requires a central compressor and tubing network. | Requires stable voltage (AC or DC) and cabling. |

| Quality Control | Must have Clean, Dry Air. Moisture and dirt will destroy seals and solenoids. | Must have stable power free of surges to protect circuit boards. |

| Maintenance | Check for air leaks and filter regulators regularly. | Check battery backups and seal integrity for moisture ingress. |

| Footprint | Actuators can be bulky, especially with spring-return units. | Generally more compact, but requires clearance for wiring. |

Key Takeaway: If you have the air infrastructure and need safety/speed, go pneumatic. If you need precision control or lack air supply, go electric. Our team ensures every automated assembly is tested to API and ISO standards before it leaves our shop.

Frequently Asked Questions (FAQ)

Which is better for outdoor freezing environments?

Generally, electric actuators have the advantage in extreme cold. Pneumatic systems are vulnerable to moisture freezing inside the air lines or the actuator itself, which can block the air supply and cause failure. If you must use pneumatic in freezing zones, you need rigorous air drying systems. Electric units, on the other hand, are self-contained and can be equipped with internal heaters to maintain operation efficiency regardless of the environmental conditions.

Can electric actuators replace pneumatic in high-speed applications?

In most cases, no. If your system requires a rapid reaction time—like an emergency shutdown—pneumatic actuators are the superior choice. They release stored energy instantly. Electric actuators rely on gears and motors, meaning they are naturally slower and limited by their duty cycle. While high-speed electric options exist, they are significantly more expensive and larger than a standard pneumatic setup.

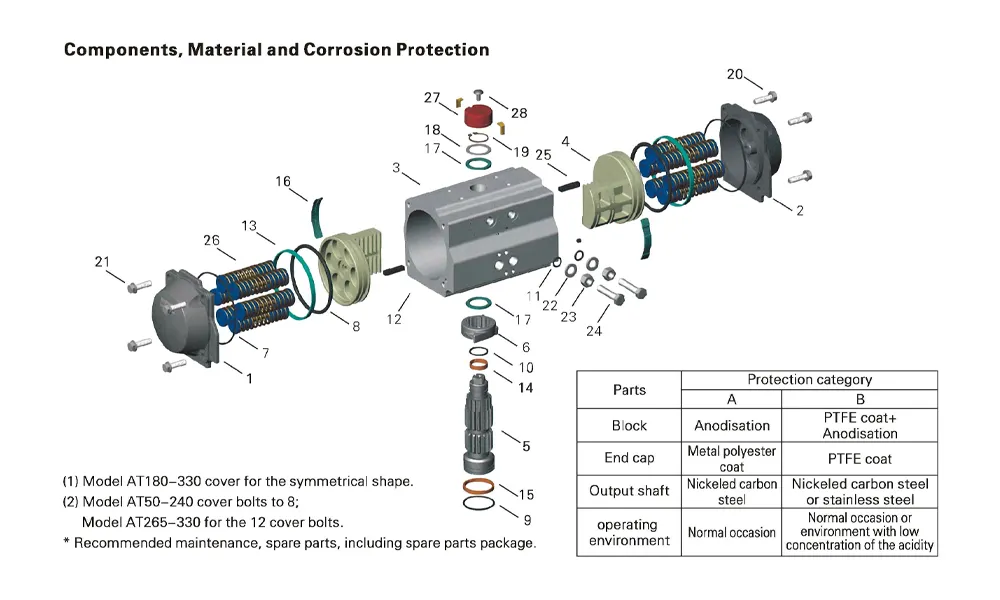

Why do pneumatic valves require “Clean, Dry Air”?

Using clean dry air is non-negotiable for reliability. Moisture causes corrosion inside the cylinder, while dust and debris act like sandpaper, destroying the seals and O-rings. This damage leads to air leaks and a drop in torque output. At our Valve Automation Center, we emphasize that poor air quality is the number one cause of pneumatic failure. Installing proper filtration and drying equipment protects your investment and reduces maintenance requirements.

Still Unsure Which Actuator Fits Your Process? Choosing between pneumatic and electric isn’t always black and white. At Delco Valves, our engineering team is ready to analyze your P&ID drawings and system requirements to recommend the most cost-effective solution.

👉 [Contact Our Valve Automation Center] today for a free consultation or to request a quote for your next project.

About the Author Delco Valve Engineering Team With over 20 years of experience in flow control automation, our team specializes in configuring valve packages for the Oil & Gas and Mining sectors. We ensure every actuator meets rigorous API standards.

- PREV: Pneumatic Knife Gate Valve: Features, Application Areas, and Selection Guide

- NEXT: Not NEXT