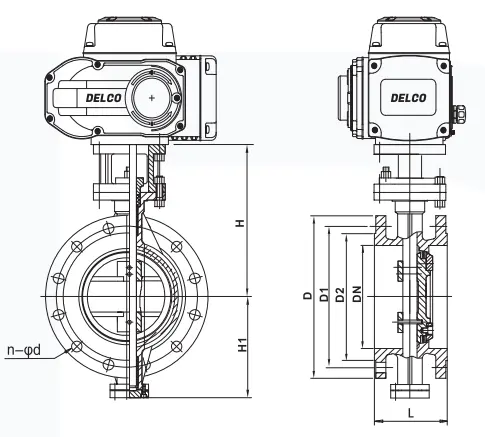

DK56-FB-G Electric Stainless Steel Hard Seal Flange Butterfly Valve - High Temperature & Abrasion Resistant

The DK56-FB-G Electric Butterfly Valve is built for superior reliability in severe service conditions. It features durable Stainless Steel (SS304/SS316) construction for excellent corrosion resistance and a robust Hard Seal (often Metal-to-Metal) design. This hard seal provides exceptional resistance to high temperatures, high pressure, and abrasive media, making it indispensable for applications involving steam, hot gases, and refining processes where soft-seated valves would fail. The flanged connection ensures a high-integrity, stable mounting interface for critical automated control.

Size Range: DN40-DN1200

Size Range: DN40-DN1200

Material:Cast Iron, WCB, SS304/316 etc.

Material:Cast Iron, WCB, SS304/316 etc.

Connection Standard: GB / ANSI / JIS /DIN

Connection Standard: GB / ANSI / JIS /DIN

Features

A high-performance electric butterfly valve featuring a stainless steel body and a hard seal design for secure, automated control of high-temperature, high-pressure, and abrasive fluids.

✅Extreme Durability (Hard Seal): The Hard Seal design (often utilizing specialized metal alloys) provides superior resistance to wear, heat, and high differential pressures, allowing the valve to be used reliably in severe throttling and isolation applications.

✅Corrosion Resistance (Stainless Steel): Constructed from high-grade Stainless Steel (SS304 or SS316), the valve offers excellent general corrosion resistance, suitable for a wide range of industrial fluids, chemicals, and environments.

✅Secure Flanged Connection: The flanged end connection ensures a standardized, high-integrity, and stable seal to the pipeline, which is vital for maintaining safety and operational integrity under high temperature and pressure.

✅Reliable Electric Automation : Equipped with the electric actuator, the valve provides fast, reliable quarter-turn operation for automated on/off control and rapid process isolation.

✅High Flow Efficiency: The inherent butterfly valve structure provides excellent flow characteristics and a low pressure drop, optimizing the energy efficiency of bulk fluid and gas transfer systems.

Photo

Photo

Parameters

Industry Applications

-

Water Treatment

Chemical dosing (chlorine, pH adjusters), filtration systems -

Chemical Processing

Acid/alkali transfer, solvent blending lines -

HVAC Systems

Chilled water control, heat recovery units -

Aquaculture

Seawater flow diversion, ozone injection -

Plating Plants

Electrolyte management, waste neutralization

Browse our case studies or talk directly with our engineers to discuss your application.

Send Your Inquiry

Not sure which valve fits your project? Our engineers provide fast selection support and OEM customization.

For a faster and more precise quotation, kindly include details such as:

- The model or features you are looking for

- Your estimated purchase quantity

- Any OEM / branding requirements

- Target market or application