Pneumatic Fluorine-Lined Flanged Ball Valve Corrosion-Resistant PTFE/PTFE-F46

The Pneumatic Fluorine-Lined Flanged Ball Valve is engineered for superior automation and isolation in the most aggressive chemical applications. The entire inner cavity and wetted surfaces of the valve body are meticulously lined with advanced fluoroplastics (such as PTFE or PTFE-F46), providing extreme resistance against strong acids (like sulfuric and hydrochloric acid), powerful alkalis, and various organic solvents. The full bore design ensures smooth, unrestricted flow and minimizes medium residue. Paired with a pneumatic actuator, this flanged valve delivers fast, reliable quarter-turn shutoff, making it essential for corrosive medium conveying systems in the chemical, electroplating, and pharmaceutical industries, capable of handling temperatures up to 150℃.

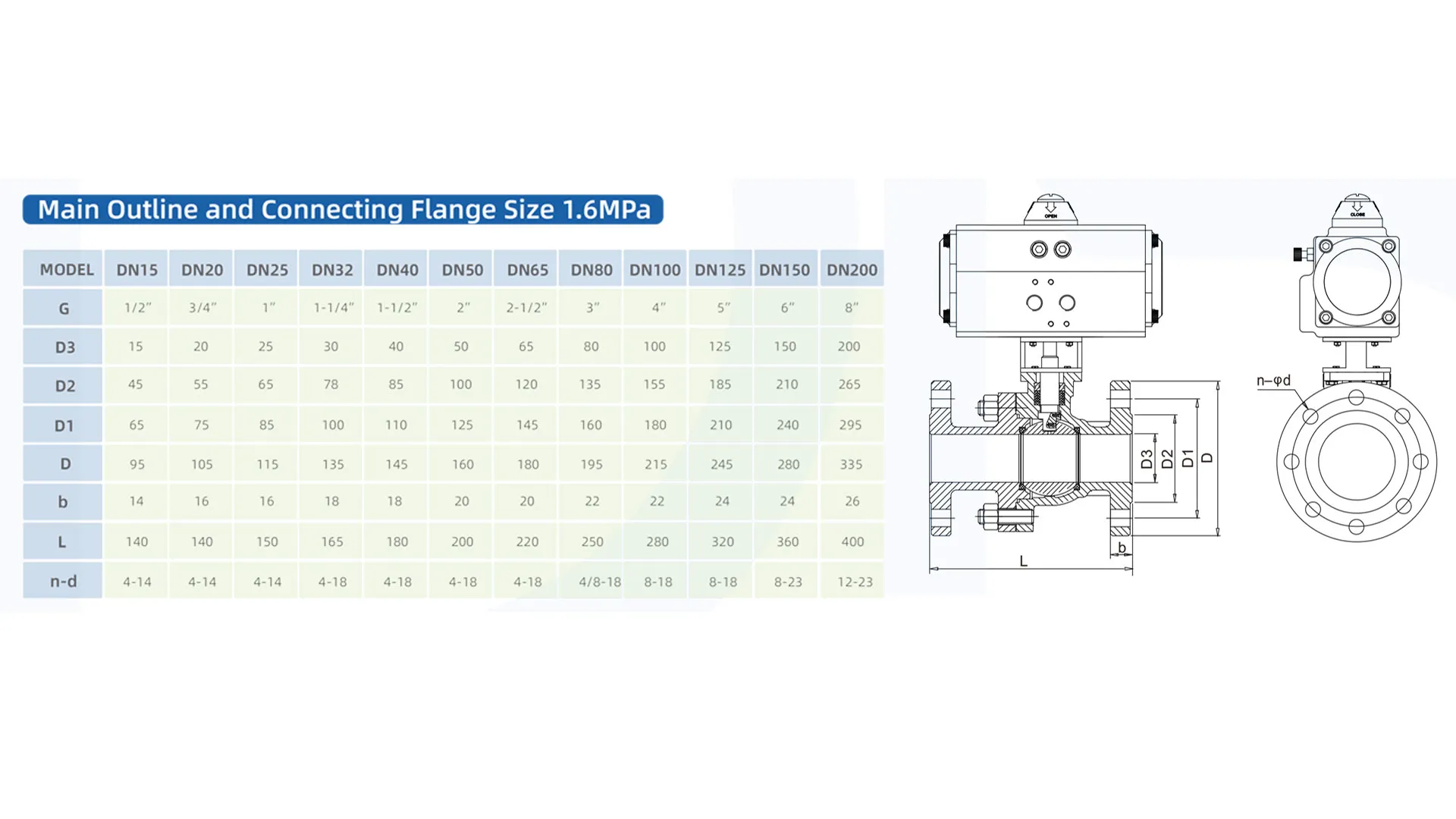

Size Range: DN15-DN350

Size Range: DN15-DN350

Material: WCB, Stainless Steel etc.

Material: WCB, Stainless Steel etc.

Connection Standard: GB / ANSI / JIS /DIN

Connection Standard: GB / ANSI / JIS /DIN

Features

A pneumatic flanged ball valve featuring a full fluoroplastic lining (PTFE/F46) for extreme corrosion resistance, designed for fast, automated isolation in chemical conveying systems operating up to 150℃.

✅Extreme Chemical Immunity: The comprehensive fluoroplastic lining (PTFE/F46) acts as a robust barrier, making the valve highly resistant to nearly all corrosive media, including strong acids, strong alkalis, and aggressive organic solvents.

✅Full Bore Design: Features a full bore flow path, significantly reducing pressure drop, maximizing media transfer efficiency, and preventing the buildup or residue of highly viscous or corrosive fluids.

✅Wide Temperature Adaptability: Suitable for operational temperatures ranging from -40℃ up to 150℃(depending on the specific lining material), accommodating a broad range of industrial processes.

✅Fast Pneumatic Isolation: The pneumatic actuator provides immediate, high-speed, quarter-turn actuation, enabling reliable and quick isolation of dangerous or time-sensitive corrosive flows.

✅Secure Flange Connection: The flanged connection ensures a robust, high-integrity seal with the pipeline, vital for maintaining safety and preventing leaks when transporting hazardous and corrosive media

Photo

Photo

Parameters

Industry Applications

-

Water Treatment

Chemical dosing (chlorine, pH adjusters), filtration systems -

Chemical Processing

Acid/alkali transfer, solvent blending lines -

HVAC Systems

Chilled water control, heat recovery units -

Aquaculture

Seawater flow diversion, ozone injection -

Plating Plants

Electrolyte management, waste neutralization

Browse our case studies or talk directly with our engineers to discuss your application.

Send Your Inquiry

Not sure which valve fits your project? Our engineers provide fast selection support and OEM customization.

For a faster and more precise quotation, kindly include details such as:

- The model or features you are looking for

- Your estimated purchase quantity

- Any OEM / branding requirements

- Target market or application