Home / Product / Special Valve /

Home / Product / Special Valve /

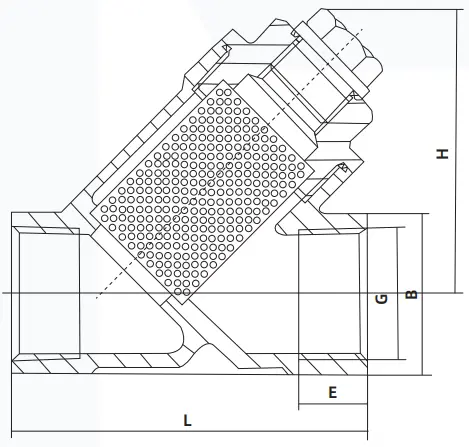

SY11 Y-Strainer for Pipeline Protection and Particle Filtration

The DELCO SY11 Y-Strainer is a crucial component designed to filter mechanical impurities from fluid media, safeguarding downstream equipment from wear and clogging. Available in durable materials like WCB and Stainless Steel (CF8/CF8M), it handles pressures from PN1.6 to PN6.4. Featuring a removable mesh cartridge, the Y-Strainer offers high efficiency, easy maintenance, and long-term protection for pumps, valves, and instruments.

Size Range: DN15-DN50

Size Range: DN15-DN50

Material: WCB, Stainless Steel etc.

Material: WCB, Stainless Steel etc.

Thread Standard: G/BSP/NPT etc.

Thread Standard: G/BSP/NPT etc.

Features

High-Efficiency Filtration and Ease of Maintenance

✅ Essential Equipment Protection: The primary function of the Y-Strainer is to filter out solid particles, rust, sand, and other mechanical impurities present in the medium. This process is vital for protecting sensitive and expensive equipment downstream, such as control valves, pumps, and flow meters, from damage and premature failure.

✅ High Working Pressure Range: Built to accommodate demanding industrial systems, the Y-Strainer is available across a wide pressure spectrum, ranging from PN1.6 up to PN6.4 (1.6 MPa to 6.4 MPa), ensuring structural integrity under high operating loads.

✅ Corrosion-Resistant Material Options: The strainer is offered in three main material specifications: SY11-C (WCB) for general fluids (water, oil, gas), SY11-P (CF8 / SS 304 equivalent) for nitric acid, and SY11-R (CF8M / SS 316 equivalent) for acetic acid and more aggressive media. The mesh itself is available in 304 or 316 Stainless Steel.

✅ Simple and Quick Maintenance: The 'Y' configuration allows for easy access to the filter element (cartridge). When cleaning is required, the filter cover (bonnet) can be quickly removed to take out and clean the removable cartridge before re-installation, minimizing process downtime.

✅ Broad Temperature Applicability: The standard WCB strainer is rated for temperatures from -29 ℃ up to 180 ℃, making it suitable for both cold and high-temperature industrial processes.

Photo

Photo

Parameters

Industry Applications

-

Water Treatment

Chemical dosing (chlorine, pH adjusters), filtration systems -

Chemical Processing

Acid/alkali transfer, solvent blending lines -

HVAC Systems

Chilled water control, heat recovery units -

Aquaculture

Seawater flow diversion, ozone injection -

Plating Plants

Electrolyte management, waste neutralization

Browse our case studies or talk directly with our engineers to discuss your application.

Send Your Inquiry

Not sure which valve fits your project? Our engineers provide fast selection support and OEM customization.

For a faster and more precise quotation, kindly include details such as:

- The model or features you are looking for

- Your estimated purchase quantity

- Any OEM / branding requirements

- Target market or application